2.4. Con nect ing the com pressed-air sup ply

Check com pressed-air pip ing for cor rect in stal la -

tion and as sem bly.

Check fit tings, length and qual ity of the hose con -

nec tions for agree ment with re quire ments.

Check all com pressed-air lines for leak ages.

You need a com pressed-air sup ply with 5 - 6 bar

(72.52-87.02 PSI) sys tem overpressure. The air

should be free from oil and wa ter, if pos si ble.

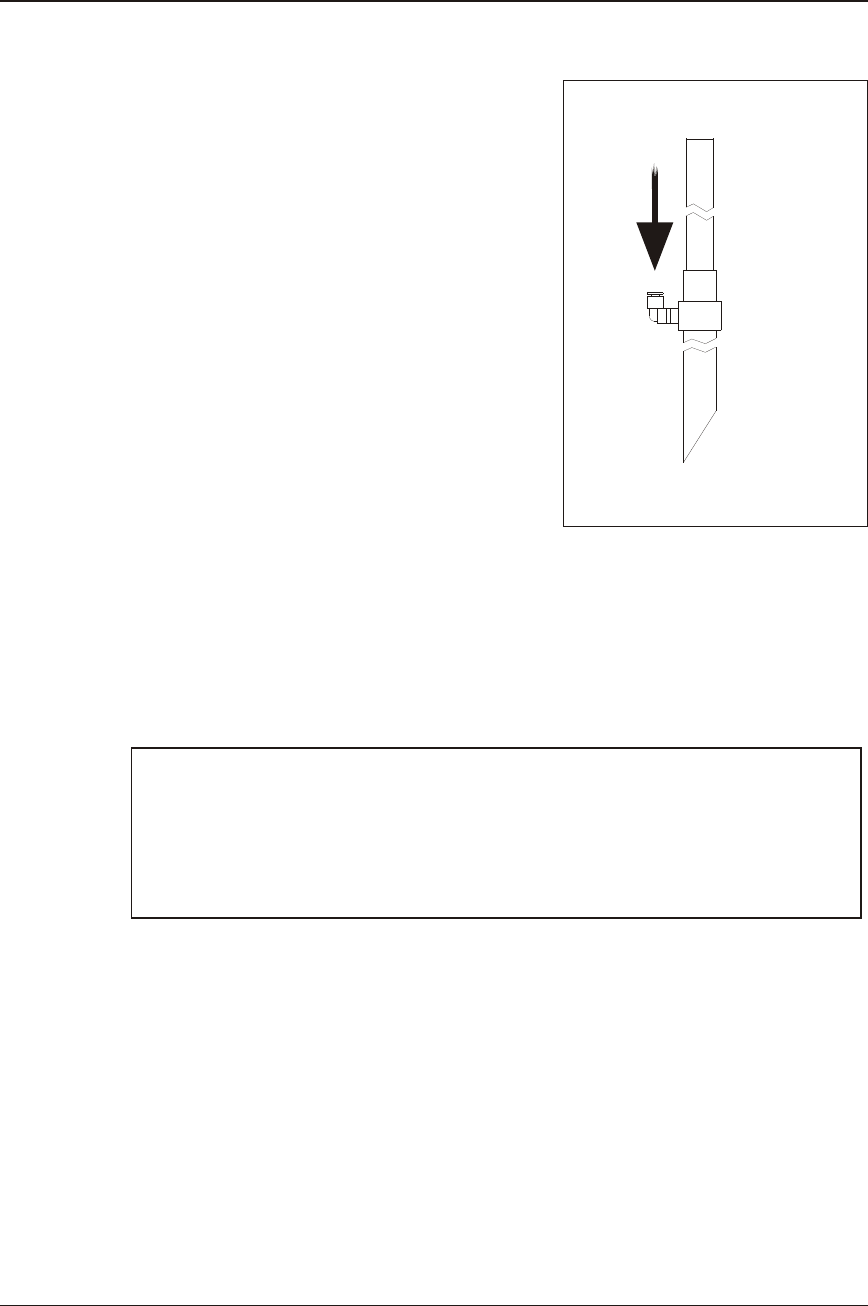

Con nect the com pressed-air hose, which is part

of the sup ply, to the in jec tor tube and to the con trol

and main te nance unit. To this end, the com -

pressed-air hose is firmly pressed into the con -

nect ing sockets.

Con nect the con trol and main te nance unit to the

com pressed-air sup ply (max. in put pres sure 10 bar (145.03 PSI) sys tem

overpressure).

Set the pres sure on the pres sure re ducer at 5 - 6 bar (72.52-87.02) PSI.

F

Max i mum in put pres sure 10 bar (145.03 PSI) (sys tem

overpressure).

Max i mum out put pres sure 6 bar (87.02 PSI).

006-4MS

SSV 05

In stal la tion in struc tions 17