10

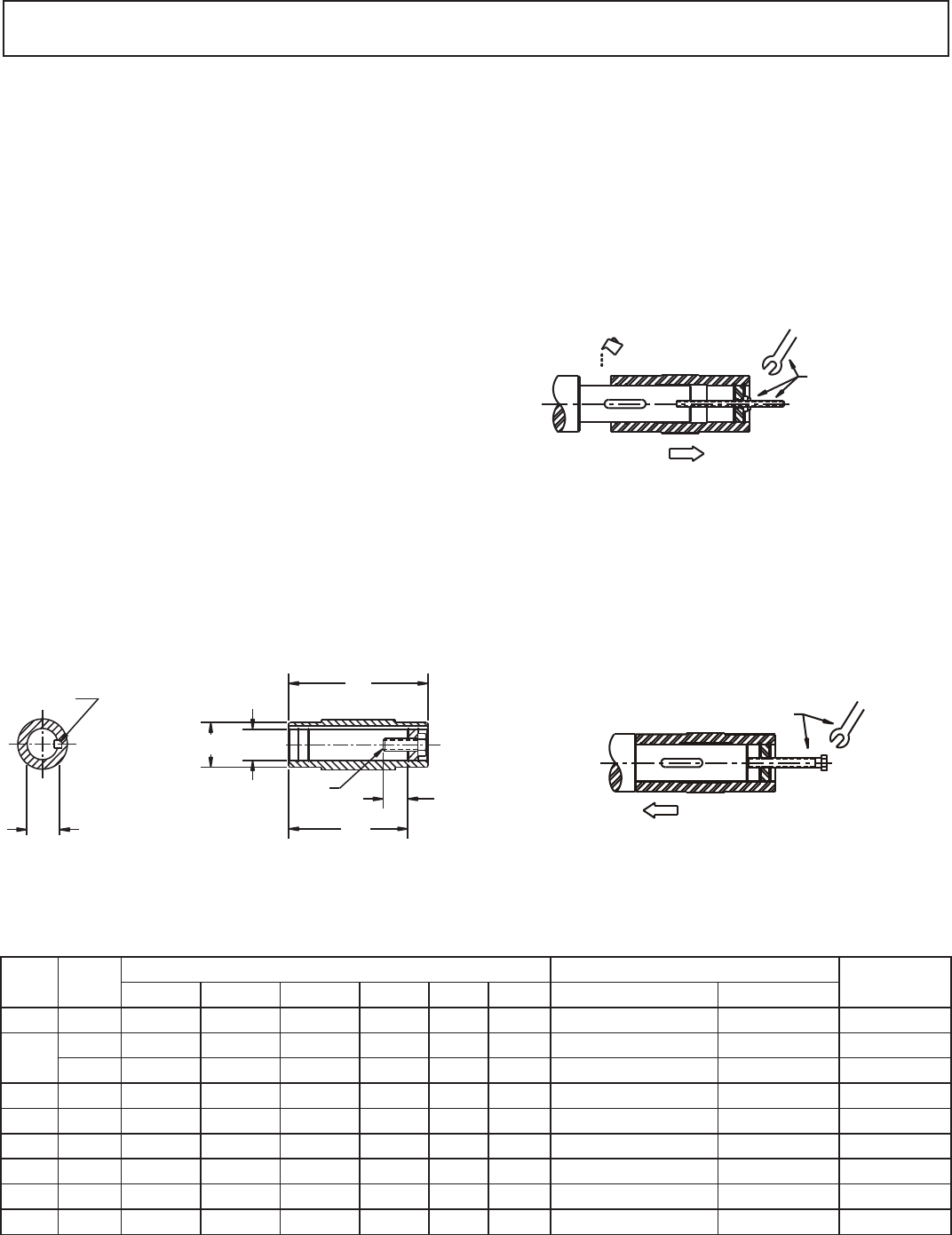

1.6 Mounting Of Reducer with Finished Bore Shaft

1.6.1 Check the internal bore of the reducer and make sure the

snap ring and washer are in the end of the shaft bore opposite

the entry side of the driven shaft.

1.6.2 Check the driven shaft to make sure it is free from

burrs and any rust preventative coating. Lubricate the driven

shaft to ease mounting with reducer. (Anti-Fretting grease is

recommended only for nished bore designs). A lifting lug is only

for lifting the weight of the reducer/gearmotor.

WARNING! (Do not use the lifting lug on the gear housing to

lift additional attached assemblies to avoid overloading the

lifting lug). Never lift gear unit by its output shaft.

1.6.3 Check the driven shaft to ensure the end is tapped. Install

the shaft key in the keyseat.

1.6.4 Rotate the OtN input until the hollow output shaft is aligned

with the key in the driven shaft.

1.6.5 The OtN gear shaft is mounted on the driven shaft using a

threaded rod, and screwed into the shaft.

By then threading a nut down onto the washer in the reducer

shaft, the shaft is smoothly inserted into the cylindrical bore of the

reducer shaft.

NOT SUPPLIED

REMOVAL

VG

EH

UY

UF U

M

Key

Output Shaft

MH

1.6.6 Replace the threaded rod with the bolt that is supplied with

the OtN unit. Thread it into the driven shaft and tighten to the

required torque. See bolt torque as shown in Table 1.2.5.

1.6.7 Install the hollow shaft cover onto the gear housing

opposite the driven shaft with the two (2) screws provided with

the cover.

1.6.8 Drive Shaft Recommendations - Its best to use the keeper

bolt to pull the driven shaft into the quill up against a shoulder on

the driven shaft.

1.7 Dismounting of the Reducer from driven shaft

1.7.1 Secure the reducer weight.

1.7.2 Thread in a long bolt that has the same thread design as

the threaded core of the reducer shaft’s washer (see Table 7-1

below). By tightening down that bolt, the driven shaft will be

separated smoothly from the reducer shaft bore.

Finished Bore Mounting

Gear

Frame

Version

Reducer Shaft Driven Shaft

Keeper Washer

Thread UNC

EH U UF UY VG MH Key

1

M (inches)

31 S2 5.12 1.250 1.77 1.372 4.31 0.37 1/4 x 1/4 x 1-1/2 7/16-14 x 1.00 5/8

32

S2 5.94 1.375 1.96 1.523 5.06 0.37 5/16 x 5/16 x 1-13/16 1/2-13 x 1.00 5/8

S3 5.94 1.250 1.96 1.372 5.19 0.37 1/4 x 1/4 x 1-13/16 7/16-14 x 1.00 5/8

33 S2 6.94 1.500 2.16 1.674 5.96 0.49 3/8 x 3/8 x 2-1/4 5/8-11 x 1.75 3/4

34 S2 8.97 2.000 2.56 2.210 7.44 0.72 1/2 x 7/16 x 2-5/8 5/8-11 x 1.75 3/4

35 S2 9.66 2.375 3.54 2.638 8.15 0.85 5/8 x 5/8 x 3-3/8 3/4-10 x 2.0 7/8

36 S2 12.44 2.750 3.93 3.037 10.89 1.23 5/8 x 5/8 x 5-1/2 3/4-10 x 2.0 1

37 S2 13.59 3.625 4.72 4.019 11.9 1.23 7/8 x 7/8 x 5-1/2 3/4-10 x 2.0 1

38 S2 13.74 4.00 5.50 4.316 11.69 1.58 1 x 1 x 6 1-8 x 2.5 1.25

1

the key for the frame 34 is supplied by Browning

MOUNTING

NOT

SUPPLIED