7

Note: Key length must be sufcient to engage the full length of

the bushing. The shaft must engage the full length of the bushing.

1.4.2 For Type 2 bushings which require one through key:

Install the bushing on the shaft, anged end rst. Align the keyway

in the bushing with the keyseat in the shaft and install the shaft key.

Position the shaft key ush against the inside ange surface of the

bushing. See Figure 1-2 Shaft Key and Bushing Location.

Note: There are three (3) series of bushing keys used in the Type

2 bushing system: rectangular, square and offset. In most cases,

the key supplied will be rectangular or offset. Use caution when

installing rectangular keys as some may visually appear square.

The key should install in the bushing keyway with a sliding type

t. The key in the driven shaft keyseat should be retained to

prevent movement.

Note: The shaft must be engaged the full length of the bushing.

1.4.3 On the side where the driven shaft enters, thread the bushing

ring onto the hollow quill until the bushing ring is ush with the end

of the hollow shaft. Rotate the gear unit input to align the keyway in

the hollow quill with the bushing/shaft key. Position the reducer on

the shaft with the bushing ring toward the bushing.

1.4.4 Slide the stabilizer ring onto the driven shaft with the small end

of the taper toward the reducer. Insert the stabilizer ring into the quill.

1.4.5 Thread the end cap and the dirt cover (not used if driven shaft

extends beyond the end of the hollow quill) onto the hollow quill until

hand tight. Do not tighten the end cap.

1.4.6 Rotate the bushing ring clockwise until the tapped holes align

with the drilled holes in the bushing ange. Prior to tightening the cap

screws, make sure the bushing key is as close as possible to the

inside ange of the bushing as shown in Figure 1-2 and the bushing

is positioned on the shaft as required in Figure 1-4. Dimensions for

rear mounting conguration with the stabilizer ring.

1.4.7 Install the bushing cap screws and tighten all the cap

screws evenly around the bushing ange to the required

torque. See bolt torque specications Table 1.2.5.

1.4.8 Tighten the end cap again until hand tight. Tighten

the setscrews to the recommended torque. See bolt torque

specications Table 1.2.5.

WARNING! The cap screws must thread into the bushing ring

and not the bushing. Threaded holes in the bushing are for

removal only. If assembled incorrectly, equipment failure and

personal injury may result.

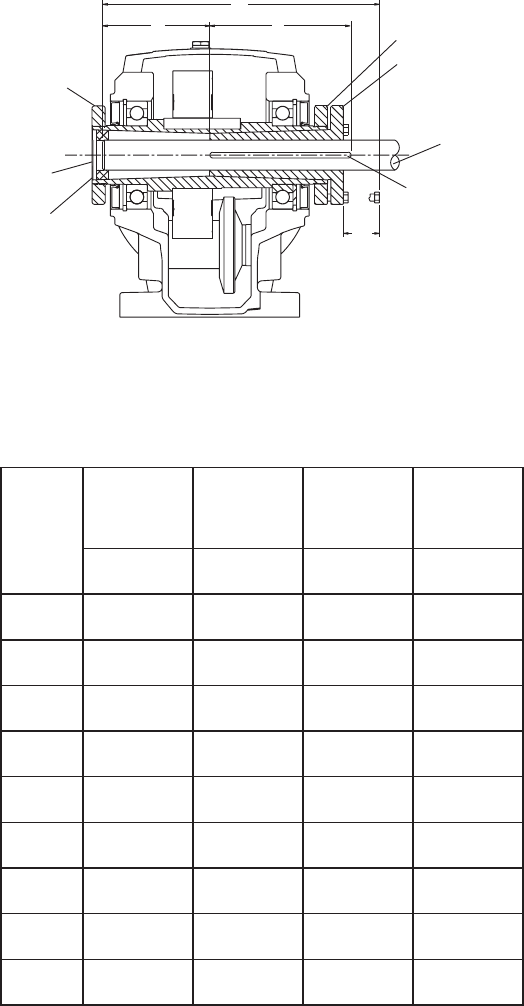

Driven

Shaft Keyseat

Dirt

Cover

Stabilizer

Ring

Driven

Shaft

MC

H

K

J

Endcap

Bushing

Bushing Ring

1.4 Mounting Conguration with Bushing on Load

Side of Reducer and Using Stabilizer Ring

Figure 1-4

Table 1-4 Dimensions for Mounting Conguration

with Bushing on Load Side of Reducer and

Using Stabilizer Ring

Gear

Frame

Bolt

Clearance

Minimum

Shaft

Mounting

Length

Minimum

Key

Connection

Length

Max.

MC H K J

31 1.50 9.11 2.88 4.73

32 1.75 10.54 4.38 4.28

33

1

1.75 10.47 4.38 4.21

33A 1.88 12.23 4.63 5.83

34 1.88 12.51 4.63 6.01

35 1.88 13.13 5.63 5.62

36 1.88 17.50 6.13 9.49

37 2.25 19.76 7.38 10.13

38 2.75 19.05 7.38 7.74

1

This design is replaced by 33A design effective Jan. 2010

1.4.1 For Type 1 bushings which require an external key and a

shaft key: Install the key (supplied with the bushing) in the external

keyseat of the bushing as shown in Figure 1-1. Install the shaft key

(not supplied) in the shaft keyseat and retain to prevent movement.

Install the bushing onto the shaft, anged end rst, align the bushing

keyway with the shaft key and position the bushing over the key.