4

402 and 402VP Instruction Manual

January 2014 LIQ_MAN_ABR_402_402VP

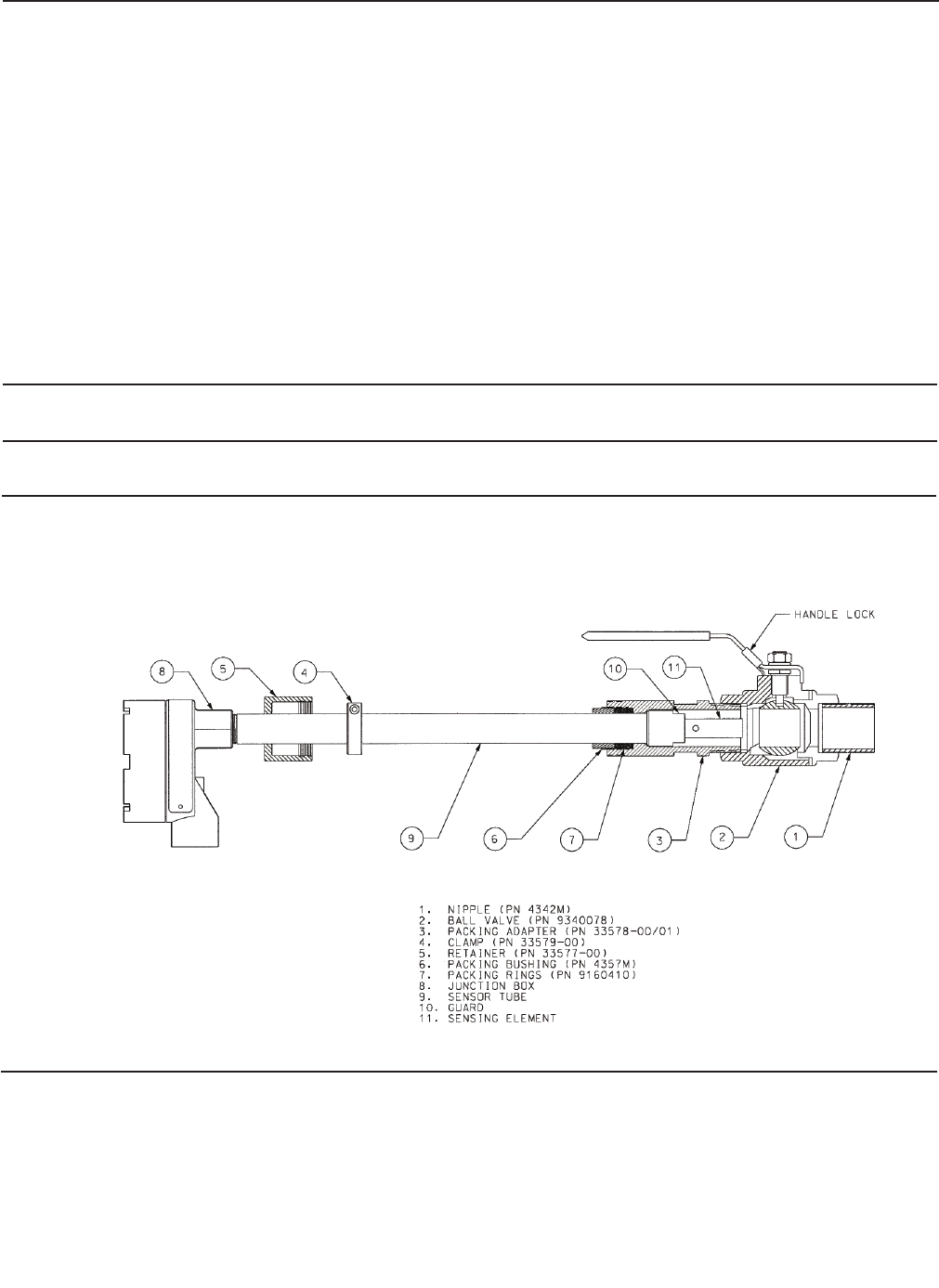

Retraction

1. Make sure the system pressure is at or below 542 kPa abs (64 psig) at the valve before proceeding. Provide adequate

working area for retraction.

2. Unscrew the retainer (5) from the packing adapter (3). If it is difcult to unscrew the retainer, system pressure may be

forcing the clamp (4) into the retainer. The packing bushing (6) may not be tight enough to hold the sensor tube (9) in

place. To prevent a sudden retraction of the sensor tube as the retainer is removed, hold onto the junction box (8) or

sensor rear to restrain the sensor.

3. If the sensor tube (9) does not slide back as the retainer is unscrewed, pull back on the junction box (8) or sensor tube

to retract the sensor.

4. If the sensor tube (9) cannot be retracted, loosen the clamp (4) using the hex key. Pull the clamp back and slowly loosen

the packing bushing (6) in 1/8-turn increments. System pressure may cause the tube to retract.

If not, pull back on the junction box (8) or sensor tube (9) to withdraw the sensor.

5. Withdraw the sensor tube until the guard (10) contacts the stop inside the packing adapter (3). The electrodes (11) are

now inside the packing adapter. See Figure 5. Slide the handle lock up on the valve handle and close the ball valve (2).

IMPORTANT!

Failure to withdraw the sensor completely may result in damage to the electrodes when the valve is closed.

6. Unscrew the packing adapter (3) from the ball valve (2) to remove the sensor and retraction assembly.

Figure 5. 402 Sensor in Retracted Position