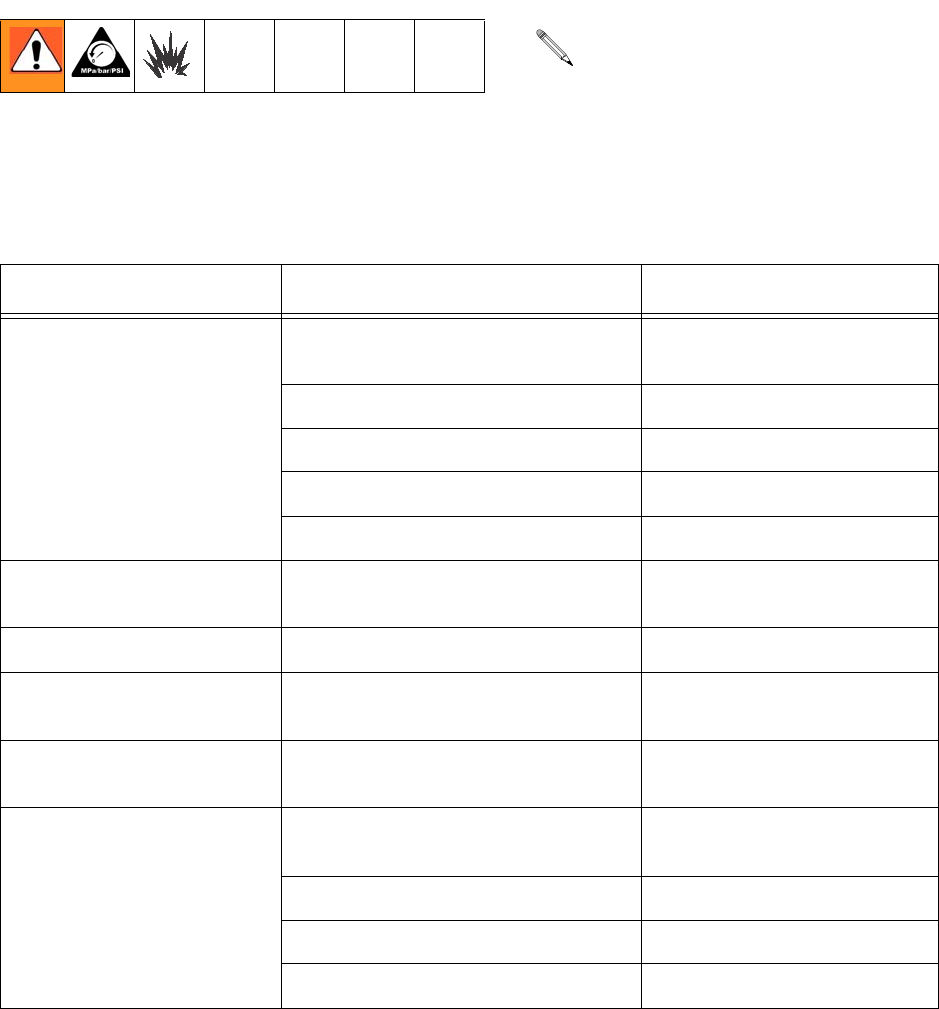

Troubleshooting

309868D 7

Troubleshooting

Check all other possible problems and solutions

before disassembling the pump. Before you trouble-

shoot problems using the table below, relieve the

pressure and disconnect the pump fluid line. If the

pump starts when the air is turned on again, the

fluid line, dispensing valve, etc., is clogged.

Problem Cause Solution

Pump fails to operate Inadequate air supply pressure or

restricted air lines

Increase air supply; clear

Closed or clogged dispensing valve Open; clear

Clogged fluid lines, hoses, valve, etc. Clear

Damaged air motor Service air motor

Exhausted fluid supply Refill and reprime or flush

Continuous air exhaust Worn or damaged air motor gasket,

packing, seal, etc.

Service air motor

Erratic pump operation Exhausted fluid supply Refill and reprime or flush

Pump operates, but output low

on down stroke

Held open or worn intake valve or pis-

ton packings

Clear; service

Pump operates, but output low

on up stroke

Held open or worn piston ball or piston

packings

Clear; service

Pump operates, but output low

on both strokes

Inadequate air supply pressure or

restricted air lines

Increase air supply; clear

Closed or clogged valves Open; clean

Exhausted fluid supply Refill and reprime or flush

Clogged fluid lines, hoses, valves, etc. Clear