Air Motor and Throat Service

8 309868D

Air Motor and Throat Service

Before You Start

• Be sure you have all necessary parts on hand.

Pump Repair Kit 246918 includes repair parts for

the pump and air motor. Use all the parts in the kit

for the best results. Parts included in the kit are

marked with one asterisk, for example (17*), in the

text and drawings. See Parts, page 14.

• Two accessory tools should be used: Padded

Pliers, 248198, are used to grip the trip rod without

damaging its surface. Gauge, 15E796, is used to

ensure the proper clearance between the poppets

and seat of the transfer valve.

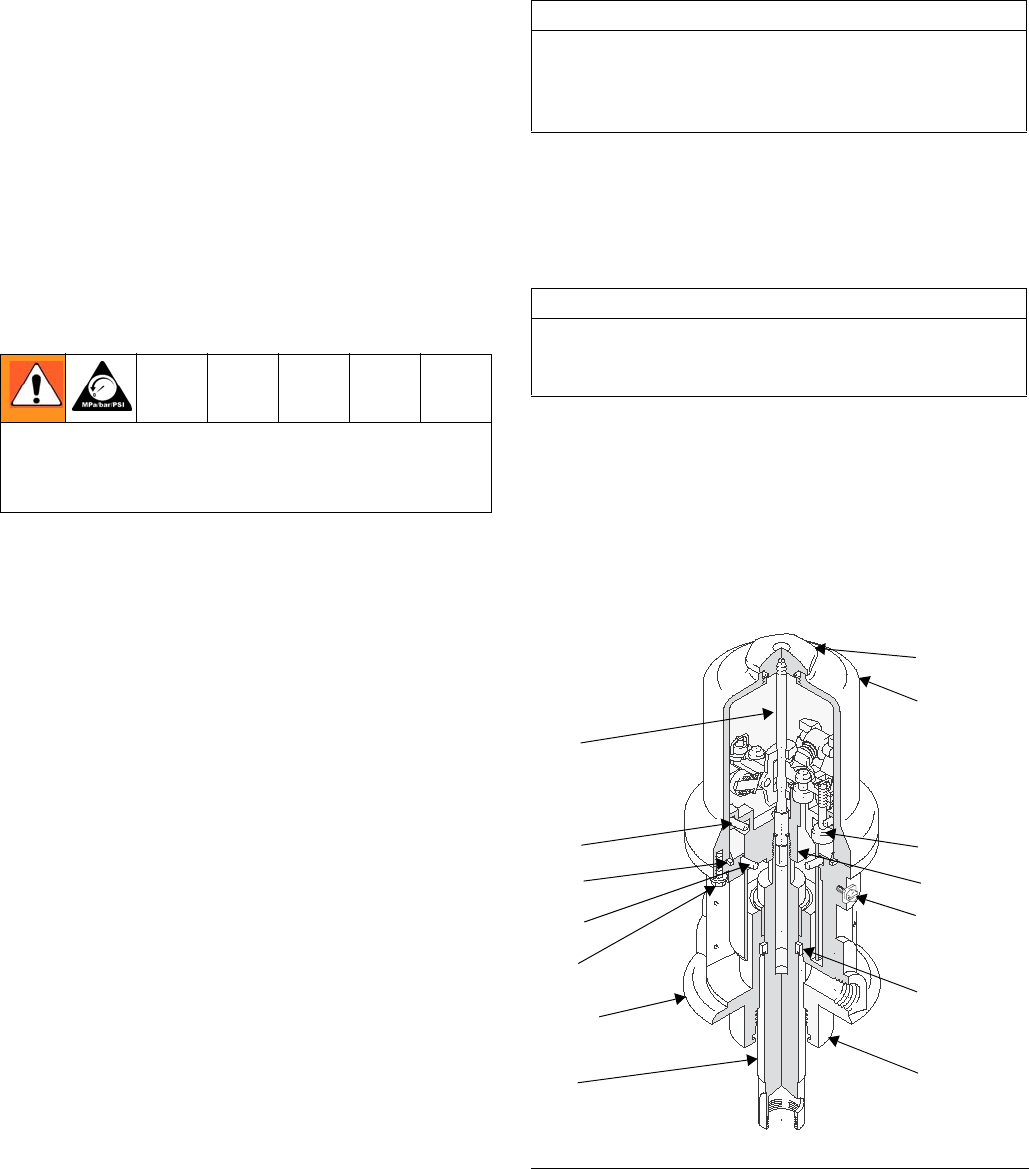

Disassembly

1. Flush the pump, and relieve the pressure.

2. Disconnect the ground wire from the grounding

screw (28a), disconnect the hoses, remove the

pump from its mounting, and clamp the air motor

base in a vise horizontally by closing the vice jaws

on the flange.

3. Use a strap wrench on the fluid cylinder (105) to

screw it out of the air motor base (28). See Parts,

page 14.

4. Pull the displacement rod (29) down as far as it will

go. See F

IG. 3.

5. Using wrenches on the flats of the displacement

rod (29) and on the flats of the fluid piston (107),

unscrew the fluid piston from the displacement rod.

Remove the ball (100) from the end of the displace-

ment rod, and remove the packing o–ring (102*)

from the fluid piston. See Parts, page 14.

6. Clamp the air motor upright in the vice by closing

the vice jaws below the flange.

7. Unscrew the cylinder cap nut (39) from the top of

the air motor cylinder (35).

8. Pull up on the cylinder cap nut (39) to expose the

trip rod, grasp the trip rod with padded pliers (Part

No. 248198), and unscrew the cylinder cap nut from

the trip rod.

9. Remove the six screws (9) holding the air motor

cylinder (35) to the air motor base (28), and care-

fully pull the cylinder straight up off of the

piston (34).

10. Pull the air motor piston/displacement rod assembly

(29, 34) clear of the air motor base (28) by pulling up

on the air motor piston.

11. Remove the o–rings (13*, 103*) and u–cup

packing (16*) from the air motor base (28). Use nee-

dle–nose pliers to remove the u–cup packing from

the bottom of the air motor base.

To reduce the risk of serious injury whenever you are

instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 6.

CAUTION

Do not damage the plated surface of the trip rod (40).

Damaging the surface of the trip rod can result in

erratic air motor operation. Use the special padded

pliers to grasp the rod.

CAUTION

To avoid damaging the cylinder wall, lift the cylinder

straight up off of the piston. Never tilt the cylinder

while you are removing it.

F

IG. 3

39

35

32*

34

28a

16*

28

40

18*

19

13*

9

flange

29

05725B