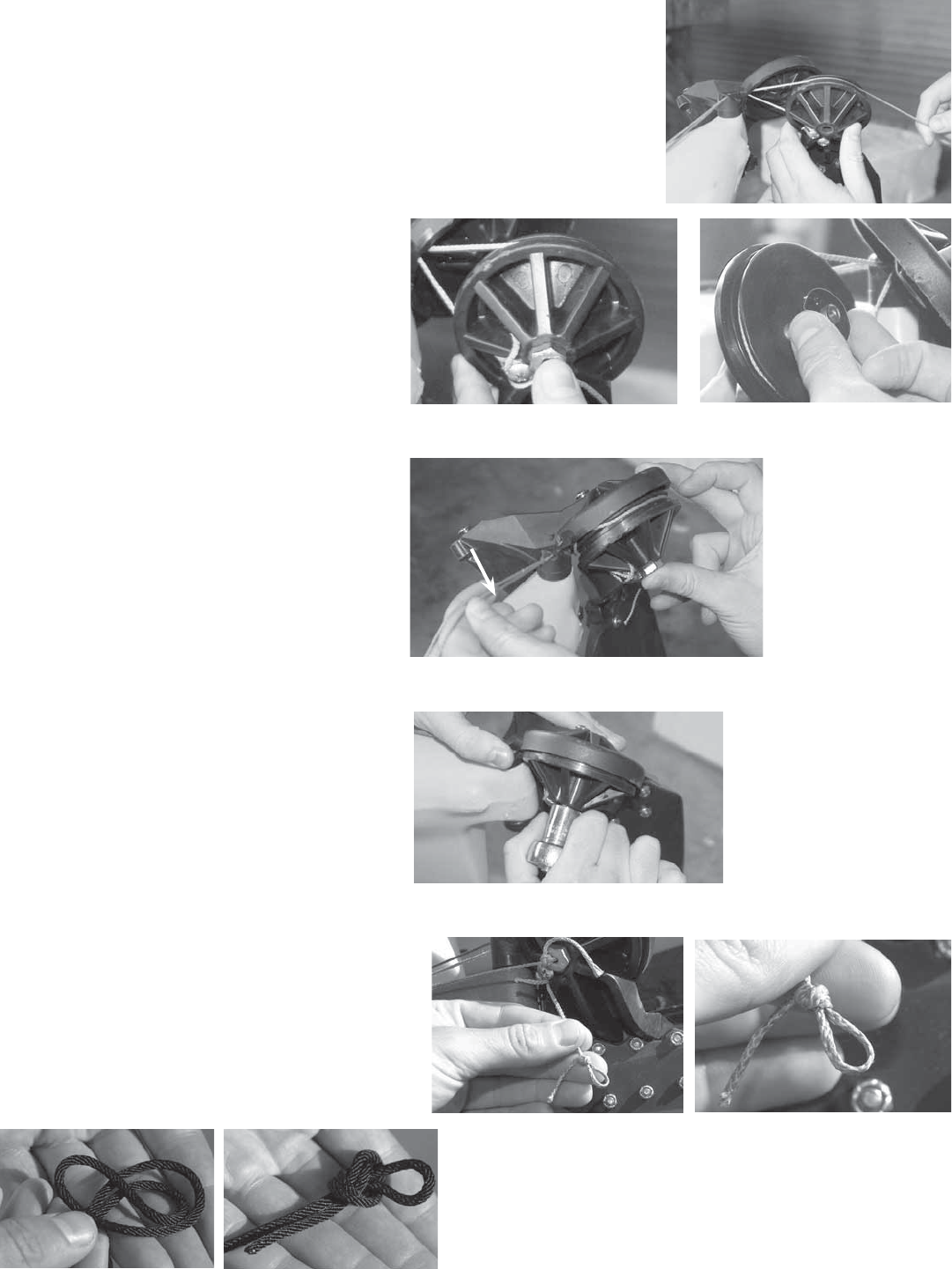

11. Now feed the UP control line through the same two holes above

the rudder pin to the inside of the rudder housing. Wrap the line so

that it goes over top and around the drum. Insert the end of the line

into the lower hole indicated in step 10 and tie a knot at the end of

the line.

12. Slide the bolt through the rudder por-

tion of the assembly and place the plastic

washer over the threaded end. Insert

then end of the bolt into the housing and

bolt the rudder assembly back together.

As you insert the rudder half into the

housing, you have to be careful to not

allow the rudder lines fall off the track

around the circular rudder drum. To pre-

vent this, pull up on the up/down control

lines that are exposed on the deck to

remove the slack and keep the lines tight

around the drum.

Thread in the bolt to hold the two halves

together. IMPORTANT NOTE: DO NOT

SCREW DOWN THE BOLT SO THAT

IT IS TIGHT. YOU ACTUALLY WANT IT

TO BE A FAIRLY LOOSE CONNECTION

ALLOWING AN 1/8”-1/4” OF

MOVEMENT. IF IT IS TOO TIGHT, THE

RUDDER WILL NOT GO UP PROPERLY.

13. Take the ends of the lines that you fed

through the rudder and make the loop so

that it is small enough to pass a screw head

through. The size of the loop isn’t that criti-

cal, but do not make it any more that 3/4”

big. See the pictures below on how to tie

the knot needed for this loop