C5

Assembly

C

(Continued)

9. Slide the rod guide down the shaft into the shock body. Be sure to

keep the piston submerged in oil the entire time.

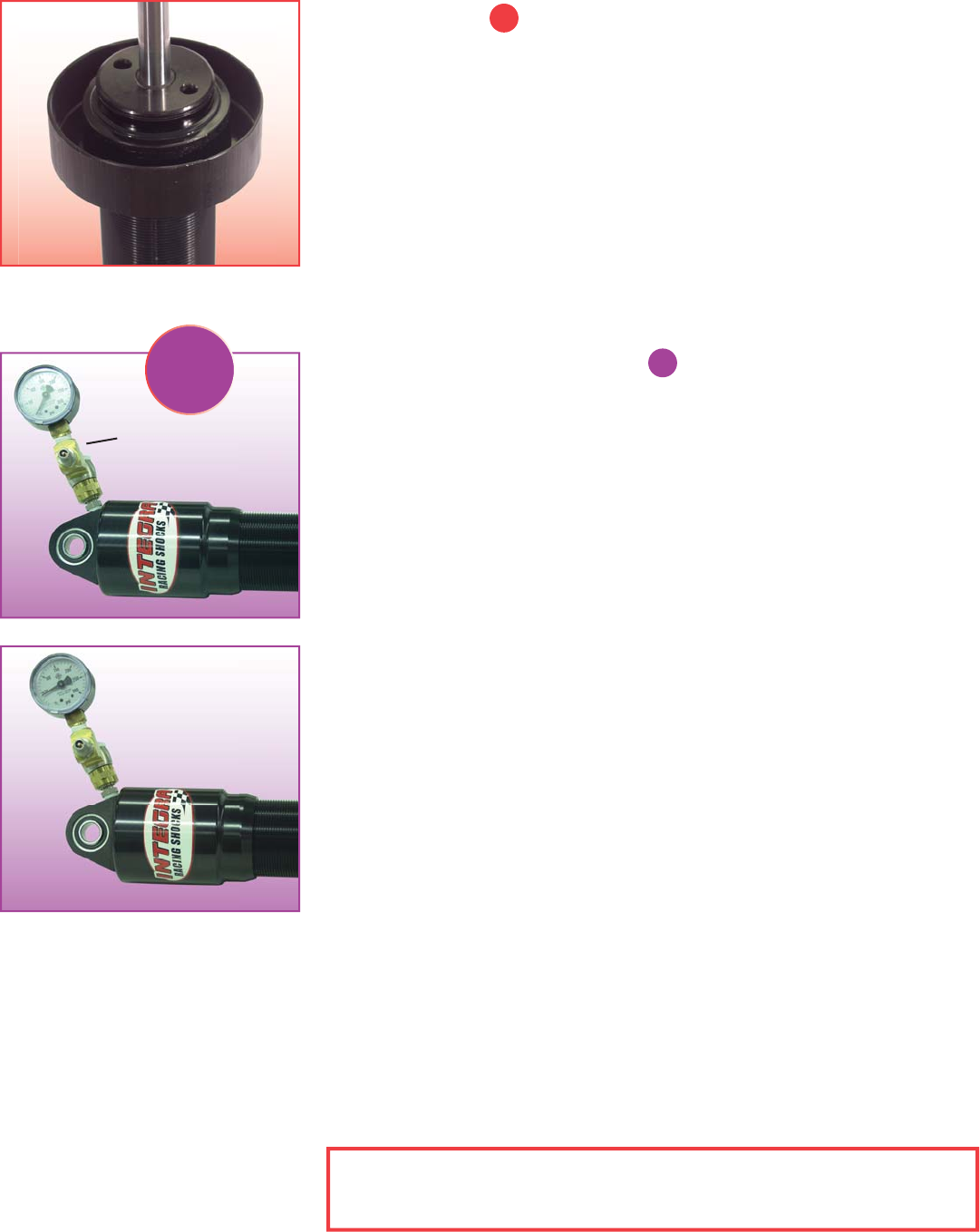

10. Tighten the rod guide into the shock body with the rod in the fully

extended position. Do this slowly so that the air below the rod guide

has an opportunity to escape past the threads

(C5).

11. Compress the rod to verify full travel, and to be certain the fl oating

piston has not moved during assembly. (If fl oating piston has

moved, piston rod will not fully compress into shock body.)

Damper Recharging

D

Once the damper has been completely reassembled and the rod guide

properly tightened, the damper must be charged with nitrogen gas:

1. Be sure the valve on top of the nitrogen tank is closed. Secure the

charging valve assembly to the nitrogen tank/regulator.

2. Back the pressure regulator on the nitrogen tank completely off.

3. Compress the rod into the damper completely.

4. Open the valve on the top of the nitrogen tank to approximately

200 PSI.

5. Back the wing nut all the way off (counter clockwise) on the infl ation

unit (part # 310-30310).

6. Screw the infl ation unit onto the damper fi ll valve. Do not over tighten.

Tighten the valve assembly only enough to eliminate any air leakage

(D1).

7. Turn the wing nut clockwise until it stops. This will push in the valve

core of the Schrader valve and allow gas to enter the shock.

8. Pressurize the shock to the desired pressure through the valve stem

on the infl ation unit. ***use nitrogen gas only***

(D2)

9. Back the wing nut all the way off (counter clockwise) on the infl ation

unit.

10. Remove infl ation unit from the shock. *** You may hear a small

amount of gas escape when the unit is removed from the shock. If the

wing nut was completely backed off, this is gas that was stored in the

unit and will not affect the setting. ***

11. Compress the rod to verify full travel in the damper without

interference. The pressure inside the damper should extend the rod

without any assistance.

IF YOU HAVE ACCESS TO A DAMPER DYNAMOMETER,

BE SURE TO TEST THE DAMPER FOR PROPER OPERATION.

D1

D

D2

Part #

310-30310