h1000 pilot

description/installation

Page 27

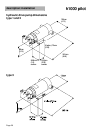

hydraulic drive pump installation

Note: When dealing with any hydraulic system great care must be taken to ensure that a high

degree of cleanliness is observed and no dirt, moisture or foreign objects are allowed to

enter the system. When bleeding your hydraulic steering system only use a good quality

ISO10 hydraulic oil, e.g. Q8 Dynobear or equivalent (10cSt at 40

0

C).

The procedure for installing the hydraulic drive pump is as follows:

1. Drain the steering system from the lowest point, usually at a cylinder coupling.

2. Fit T-pieces into the port and starboard delivery lines, couple the lines to the appropriate service

ports of the pump using flexible hydraulic hose.

3. Couple the reservoir port to the reservoir/balance line from the helm units. A low pressure,

transparent plastic tube can be used.

Note: Ensure that this line rises gradually with no down turns.

4. Refill the steering system as recommended by the manufacturer, using clean hydraulic fluid.

5. Fill the cylinder by temporarily removing the cylinder couplings and hoses at each end. Refit the

hoses securely.

6. Starting at the highest helm unit, fill the helm reservoir.

7. Slowly turn the steering wheel two turns to port and then to starboard, checking the level of fluid

in the helm unit reservoir at all times.

8. Next, turn the wheel fully in one direction until a slight pressure is felt, continuously monitor the

reservoir level.

9. Repeat in the opposite direction and continue in this manner until topping up is no longer

necessary.

10. When satisfied that the steering is fully bled manually, apply power to the pump unit.

11. Turning the wheel fully from lock to lock will cause the pump to self-purge.

12. Check the fluid level in the helm unit reservoir.

13. When the system appears to be fully functional, with the pump running and the helm hardover

check for leaks.

14. Secure all hoses and cables to prevent damage.