U.S. ELECTRICAL MOTORS

INSTALLATION AND MAINTENANCE

IV. INSTALLATION LOCATION

When selecting a location for the motor and driven unit, keep the following items in mind:

1. The location should be clean, dry, well ventilated, properly drained, and provide accessibility for inspection,

lubrication, and maintenance. Ambient vibration should be kept to a minimum. Outdoor installations on Open

Dripproof motors require protection from the elements.

2. The location should also provide adequate space for motor removal without shifting the driven unit.

3. The temperature rise of a standard motor is based on operation at an altitude not higher than 3,300 feet above

sea level. See NEMA MG-1 20.40 for normal service condition.

4. To avoid condensation inside of motor, motors should not be stored or operated in areas subject to rapid

temperature changes unless they are energized or protected by space heaters.

5. The motor should not be installed in close proximity to any combustible material or where flammable gases and/

or dust may be present, unless motor is specifically built for that environment and is U. L. labeled accordingly.

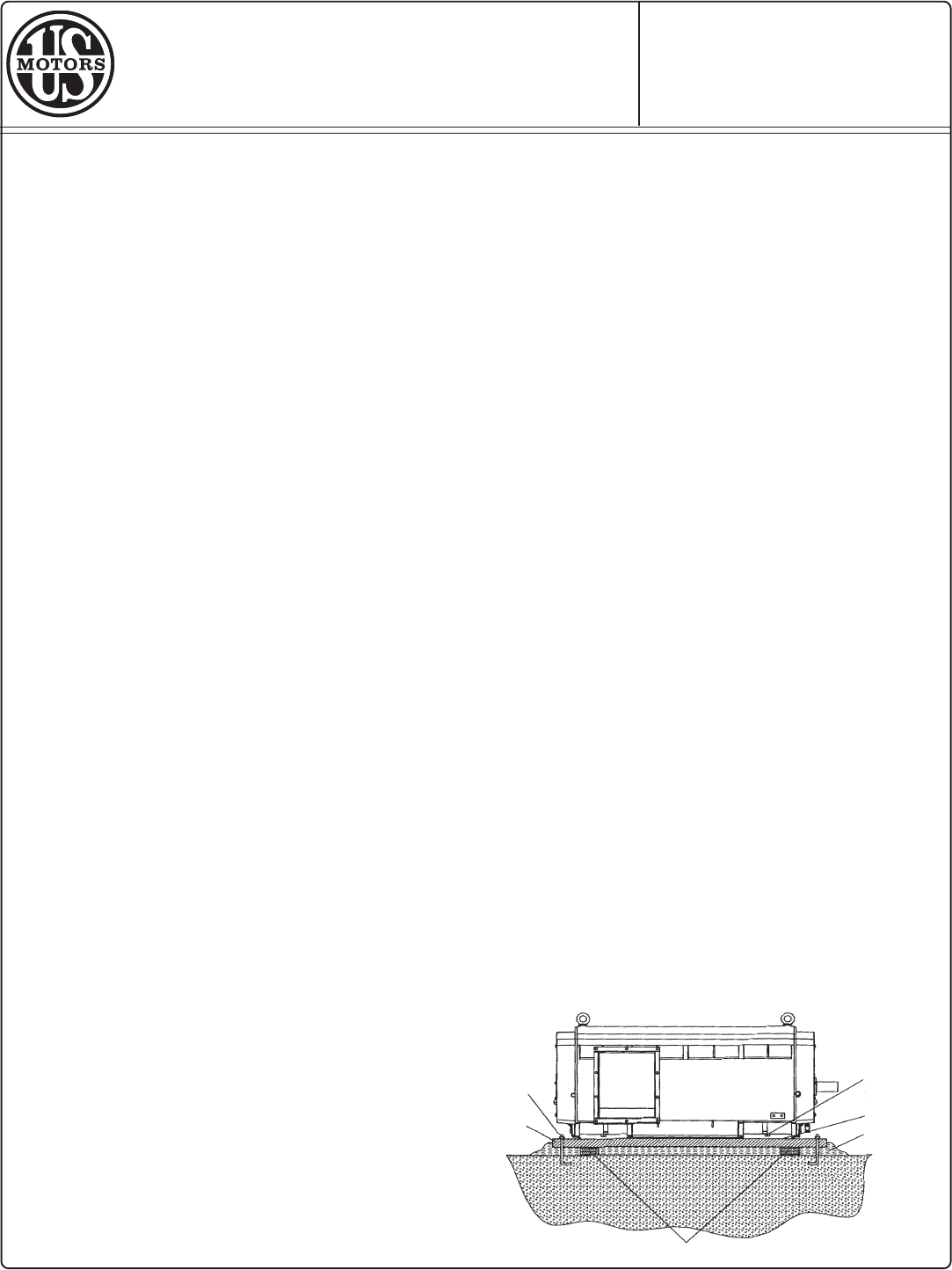

V. FOUNDATION

Concrete (reinforced as required) makes the best foundation, particularly for large motors and driven units. A

sufficient mass provides rigid support that minimizes deflection and vibration. It may be located on soil, structural

steel, or building floors, provided the total weight (motor, driven unit and foundation) does not exceed the allowable

bearing load of the support. (Allowable bearing loads of structural steel and floors can be obtained from engineering

handbooks; building codes of local communities give the recommended allowable bearing loads for different types of

soil). It is recommended that a fabricated steel base (sole plate) be used between motor feet and foundation. See

Figure 2. Base foot pads should be level and in the same plane.

Grouting

Grouting is the process of firmly securing equipment to a concrete base. This base is a continuation of the main

foundation, designed to dampen any machine vibration present and prevent the equipment from shaking loose

during operation. A serviceable and solid foundation can be laid only by careful attention to proper grouting procedure.

In practical terms, “grout” is a plastic filler which is poured between the motor sole plate and the foundation upon

which it is to operate. Being plastic, it is expected to fill all spaces and cavities before it sets or solidifies and

becomes an integral part of the principal foundation. In order to function properly, the principal foundation should be

allowed to fully set through chemical reaction and dehydration as recommended by the grout manufacturer, prior to

motor installation.

Installation

Location &

Foundation

5

FIGURE 2

TYPICAL MOTOR

MOUNTING

ARRANGEMENT

MOUNTING

BOLT

SOLE PLATE

MOTOR

MOUNTING

BOLT

SHIMS

GROUT

WEDGES