U.S. ELECTRICAL MOTORS

INSTALLATION AND MAINTENANCE

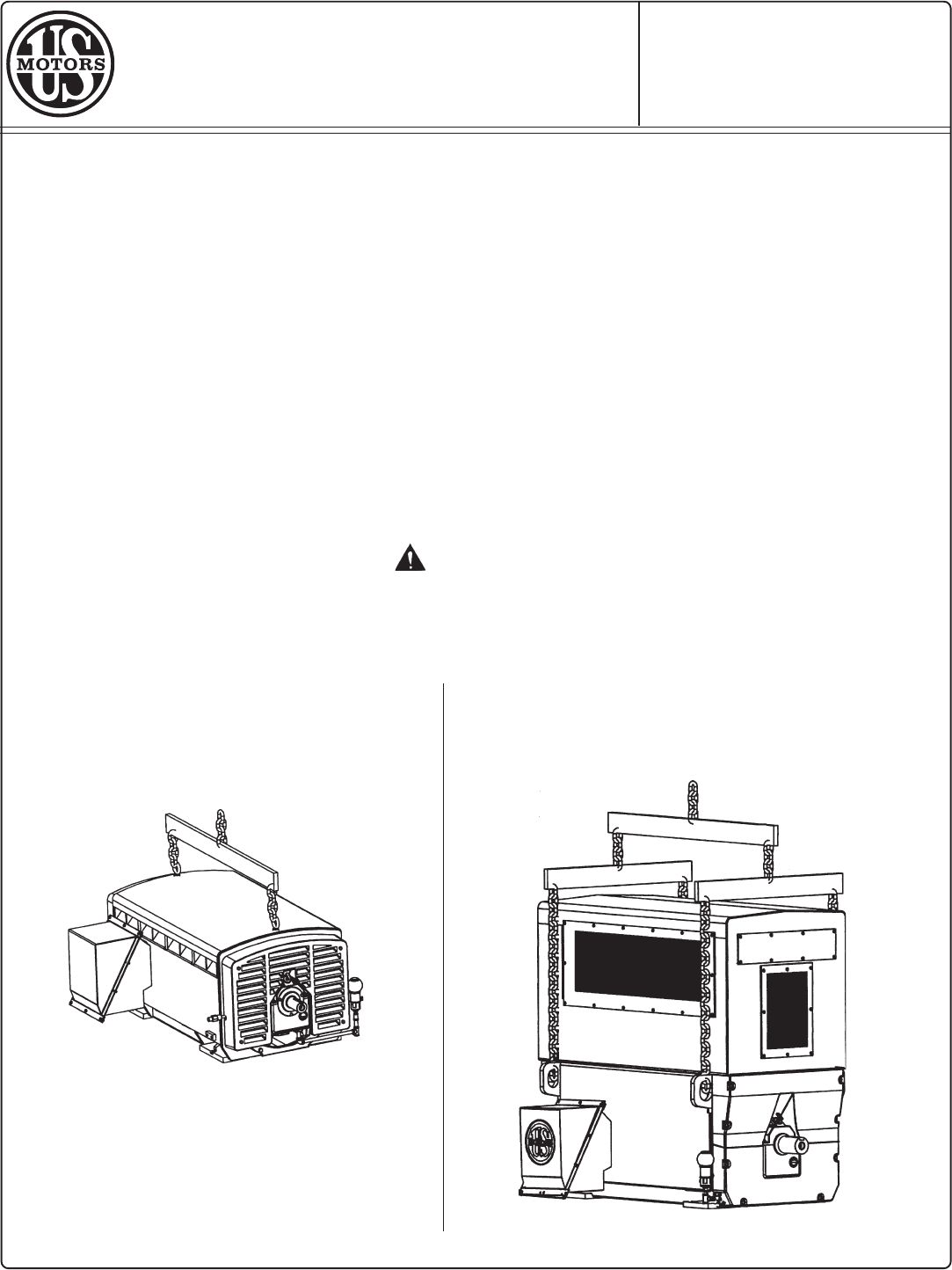

FIGURE 1B

Typical Construction With Four Lifting Lugs

FIGURE 1A

Typical Construction With Two Eyebolts

Shipment &

Handling

I. SHIPMENT

Prior to shipment, all Titan-II Motors undergo extensive electrical and mechanical testing, and are thoroughly

inspected. Upon receipt of the motor, carefully inspect the unit for any signs of damage that may have occurred

during shipment. Should such damage be evident, unpack the motor at once in the presence of a claims adjuster

and immediately report all damage and breakage to the transportation company and U.S Electrical Motors.

When contacting U.S Electrical Motors concerning the motor, be sure to include the complete motor identification

number, frame and type which appears on the nameplate (see installation record in this manual).

II. HANDLING

The equipment needed to handle the motor includes a hoist and spreader bar arrangement of sufficient strength

to lift the motor safely. The spreader bar arrangement should always be employed whenever multiple lifting lugs

or eyebolts are provided (See Figures 1A & 1B). The spreader bar should have the lifting hooks positioned to equal

the span of the eyebolts or lifting lugs. The eyebolts or lifting lugs provided are intended to lift the motor weight only.

See Table 6 for motor weights.

CAUTION

Lifting the motor by means other than specifically noted may result in damage to the

motor or injury to personnel. Note that the eyebolt on the top of WPII enclosure is intended

for lifting the tophat only.

1