U.S. ELECTRICAL MOTORS

INSTALLATION AND MAINTENANCE

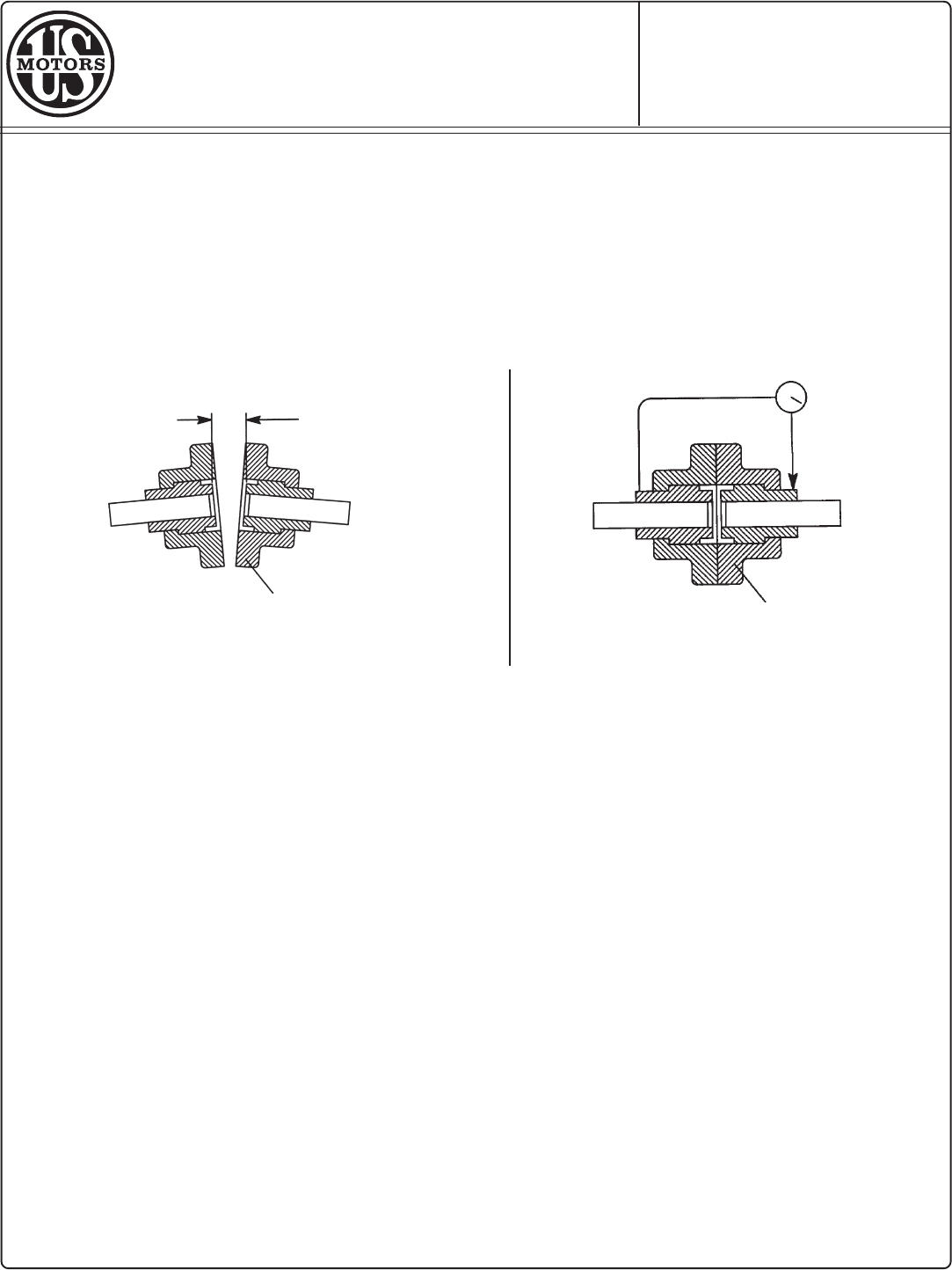

B. Parallel Alignment (See Figure 3B)

Fasten a dial indicator onto one coupling hub with the indicator button on the cylindrical surface of the

opposite coupling hub. Rotate shafts together and take readings at four points, 90° apart. Relocate motor

until total indicator movement in full rotation does not exceed .002". Transfer indicator to opposite hub and

repeat the parallel alignment procedure. Recheck angular alignment as described in Step A.

FIGURE 3

FLEXIBLE COUPLINGS

C. Soft Foot Check

Check and correct any "soft foot" condition to assure that equal pressure is exerted on each motor foot by the

following shimming procedure. Bolt all motor feet down solidly to the motor bedplate or foundation. Mount the

base of the dial indicator from the motor's foundation, and place and zero out the indicator on the motor shaft

or coupling. Back off one of the take off end bolts and check indicator for change in reading, a .001 inch

reading is maximum. Shim at foot if required and go to other take off end bolt. This procedure should be

repeated on the opposite end until no reading is greater than .001 inches.

D. Hot Alignment

It is possible for motor shaft height to change relative to the driven equipment and this should be compensated

for during the alignment procedure. Recheck parallel alignment (vertical) of coupled drive by repeating after

normal operating temperature is reached. If shimming is changed, repeat alignment procedure to the extent

necessary to assure proper alignment.

4. Electrical Connection

Refer to the motor nameplate for power supply requirements and to the connection diagram for connection

parameters. Be sure connections are tight. Recheck carefully and assure that they agree with the connection

diagram. Insulate all connections with electrical tape to insure that they will not short against each other or

to ground. Be sure the motor is grounded to guard against electrical shock. Refer to the National Electrical

Code Handbook (NFPA No. 70) and to local electrical codes for proper wiring, protection, and wire sizing. Be

sure proper starting equipment and protective devices are used for every motor. For assistance, contact the

motor starter manufacturer. Apply the above precautions to all accessories as well.

Initial

Installation

7

FLANGE

MOTOR

LOAD

FIGURE 3A

ANGULAR MISALIGNMENT

FIGURE 3B

PARALLEL ALIGNMENT

FLANGE

LOAD

MEASURE DISTANCE

BETWEEN FACES

MOTOR