U.S. ELECTRICAL MOTORS

INSTALLATION AND MAINTENANCE

CORRECTION

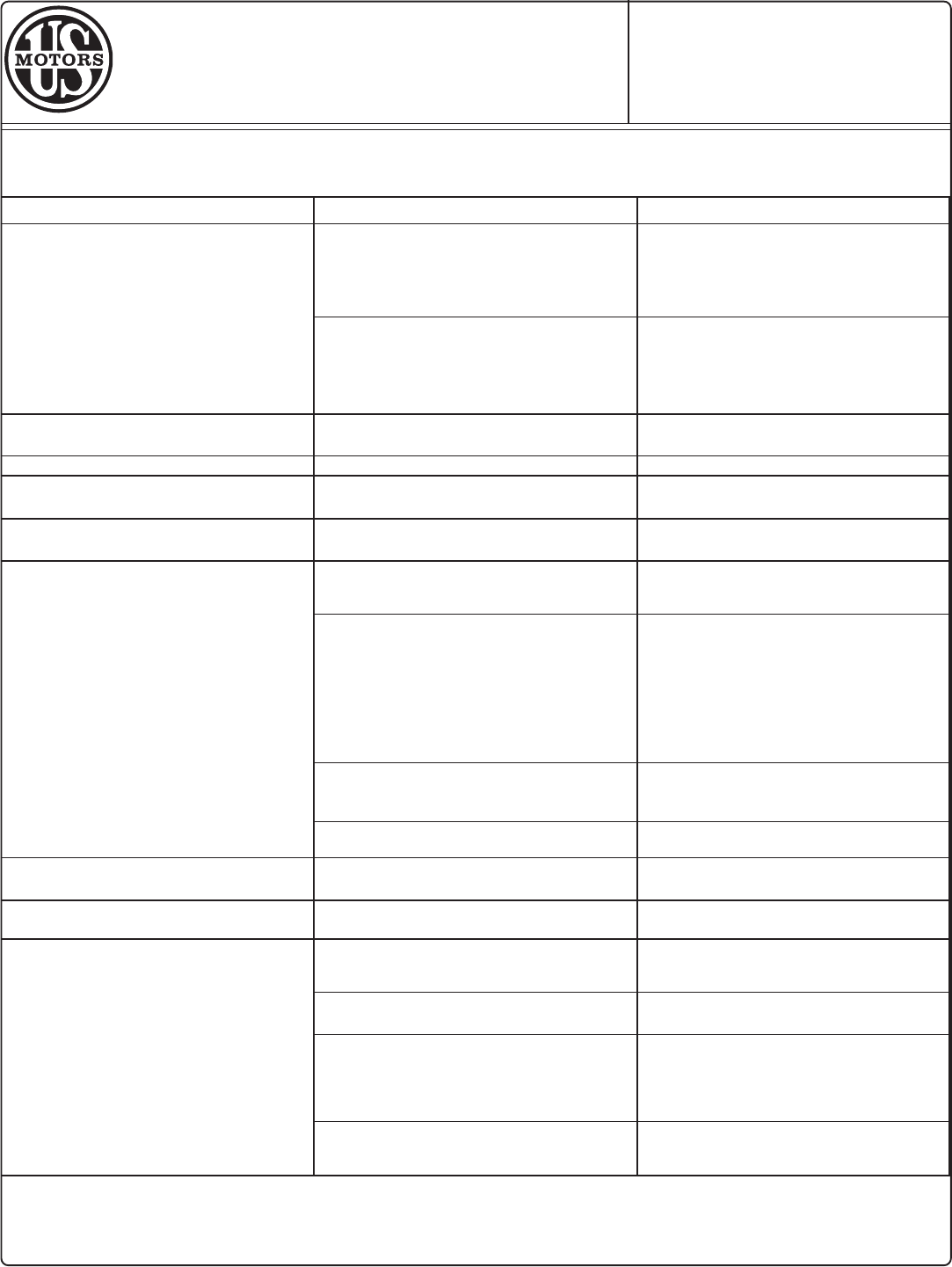

Check source of power supply. See

Safety instructions! Check overloads,

controls and fuses. Check voltage,

compare with nameplate voltage.

Disconnect motor from load to verify if

motor starts without load. Reduce

load-or replace motor with motor of

greater load capacity.

Check input voltage and proper motor

lead connection.

Balance rotor assembly.

Remove rotor assembly and clean

motor.

Replace bearing and regrease per

lubrication section.

Realign motor per initial installation

section.

Disconnect motor from driven equip-

ment. See section on safety. Run

motor unconnected and check vibra-

tion. If vibration drops dramatically,

then the driven equipment or align-

ment may be the cause of vibration.

Check base vibration level with motor

stopped.

Revise rigidity of motor base structure.

Balance rotor assembly.

Realign couplings, inspect couplings.

See initial installation section.

Realign unit. See initial installation

section.

Reduce belt tension.

Reduce thrust from driven machine.

Recheck alignment. See initial

installation section.

Relieve bearing cavity of grease to

level specified in lubrication section.

TROUBLE

Motor will not start

Excessive motor humming

Noise

Clicking

Rapid knocking

Vibration

Vibration

"following motor repair"

Fine dust under coupling with rubber

buffers or pins

Bearing overheating

XIV. TROUBLESHOOTING

Troubleshooting

POSSIBLE CAUSE

Does not rotate. Usually line trouble

single phasing at starter.

Rotates but does not come up to

speed. Load too heavy.

High voltage

Unbalanced rotor

Contaminants in air gap

Bad bearing; contaminated grease

Misalignment in coupling or feet

Vibration in driven equipment

Ambient Vibration

System natural frequency (resonance)

Rotor out of balance; balance weights

or fans shifted on rotor.

Misalignment

Misalignment

Excessive tension in belt drive

Excessive end thrust

Too much grease in bearing

16