5-1

Chapter 5

Operation

Precautions

1. Do not over pressure the piston

2. Do not increase or decrease the pressure in the gauge rapidly. Always use a metering

valve for flow control. If possible, hold a hand lightly on the weights to protect the

piston from injury. The maximum rate is 0.7 MPa (100 psi) per minute.

3. Before operation, be sure the retaining ring of the high pressure piston is securely

in place.

4. Do not operate the gauge with a dirty or sticky piston.

5. Do not rotate the pistons against the upper or lower stop longer than necessary

because the bearings, of necessity, are not lubricated.

6. Because of extremely small tolerances between mating parts, every effort should be

made to insure careful handling of gauge parts. All parts, especially those concerned

with the piston and cylinder, should be kept scrupulously clean. Acid from finger

prints can etch a piston or cylinder. Handle piston and cylinder using cotton gloves

on the hands to prevent acid etching of piston and cylinder walls.

7. Pistons and cylinders are matched assemblies. Each piston will operate properly only

in its particular cylinder.

8. Any sound which indicates metal-to-metal contact between the piston and cylinder is

a signal for the operator to stop the gauge immediately. Failure to do so may cause

damage to the piston and/or cylinder.

9. Always give the serial number of the instrument when ordering replacement parts.

10. The circular weight-loading table of the Low Range Piston must never be permitted

to enter the bore of the mating cylinder. The assembly must always be handled as

described in Chapter 6, Piston/Cylinder Cleaning Instructions. Precautions must

always be taken to prevent uninformed and inexperienced persons from carelessly

picking up this assembly for inspection.

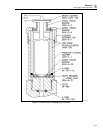

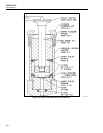

11. The Low Range Piston/Cylinder (2460-5) must always be assembled in the cylinder

housing with the O-ring relief on the cylinder in the downward position.

See Figure 5-1.