10 308-017

DISPLACEMENT

PUMP SER

VICE

Disassembly

When

disassembling the pump, lay out all removed parts

in

sequence, to ease reassembly

. Refer to Fig 6.

NOTE: Repair

Kit 222-773 is available to replace the pis

-

ton

and intake valve seals. For

the best results,

use all the new parts in the kit. Kit parts are

marked

with one asterisk, for example (1

1*).

Repair Kit 222-774 is available to replace the

throat

packings. For the best results, use all the

new

parts in the kit. Kit parts are marked with two

asterisks,

for example (3**).

1. Remove the displacement pump from the air motor

as explained on page 9. Place the pump in a vise,

with

the jaws on the outlet housing (10).

2. Hold

the flats of the priming piston rod (24) with a 12

mm wrench. Using a 22 mm wrench, unscrew the

priming

piston nut (30). Slide the priming piston (25)

and

piston guide (31) of

f the rod.

Inspect the surfaces

of

the guide (31) and piston (25) for scoring, wear

, or

other

damage.

3. Loosen the packing nut (2) using the wrench (1 10)

supplied,

or a hammer and brass rod. Remove the in

-

take

cylinder (23), using an adjustable wrench.

4. Unscrew

the intake valve housing (17) from the

cylin

-

der

(12),

using an adjustable wrench. Pull the hous

-

ing off the pump. The intake check valve assembly

(S)

should slide down the priming piston rod (24)

as

you remove the housing; if it does not slide easily ,

firmly

tap on

the top of the housing (17) with a rubber

mallet

to loosen.

5. Use an o-ring pick to remove the seal (21) from the

intake valve housing (17). Discard the seal; use a

new one for reassembly. Pull the intake valve seat

(22)

out the bottom of

the housing (17). If the seat is

difficult to remove, insert a hammer and brass rod

through the top of the housing and drive the seat

out.Take

care not to drop the check valve assembly

(S) as it comes free, and set it aside for later

.

6. Push

the displacement

rod (1) down as far as possi

-

ble, then pull it and the priming piston rod (24) out of

the

outlet housing (10) and cylinder (12).

7. Remove the packing nut (2), throat packings (3, 5)

and glands (4, 6) from the outlet housing (10). DO

NOT

remove the

fluid outlet nipple (8) and o-ring (9)

from

the housing unless they need replacement.

8. Unscrew

the handle of the bleeder valve (35) from

its

housing.

Clean the threads and the bleed hole in the

valve housing. It is not necessary to remove the

valve

housing from the outlet housing (10).

9. Use

a 400 mm adjustable wrench on the flats of the

pump

cylinder

(12) and unscrew the cylinder from the

outlet

housing (10). Remove the

o-rings (1

1). Inspect

the

inside surface of the cylinder for wear

, scoring or

other

damage by holding it up to the light at an angle

or

running a finger over the surface.

10. Inspect the outer surfaces of the displacement rod

(1) and priming piston rod (24) for wear , scoring or

other damage by holding them up to the light at an

angle

or running a finger over the surface.

11. Use

a vise with soft jaws

to hold the displacement rod

(1)

by its flats.

Place a 19 mm wrench on the flats of

the piston and unscrew the piston (13) and priming

piston rod (24) from the displacement rod (1). Re-

move

the spacer (33). Disassemble the piston guide

(14)

from the piston (13).

12.

It is not necessary to remove the priming piston rod

(24) from the piston (13) unless your inspection re-

veals scoring, wear, or other damage to either part.

To disassemble, place the piston flats in a vise and

unscrew

the rod, using a 12 mm wrench on the flats.

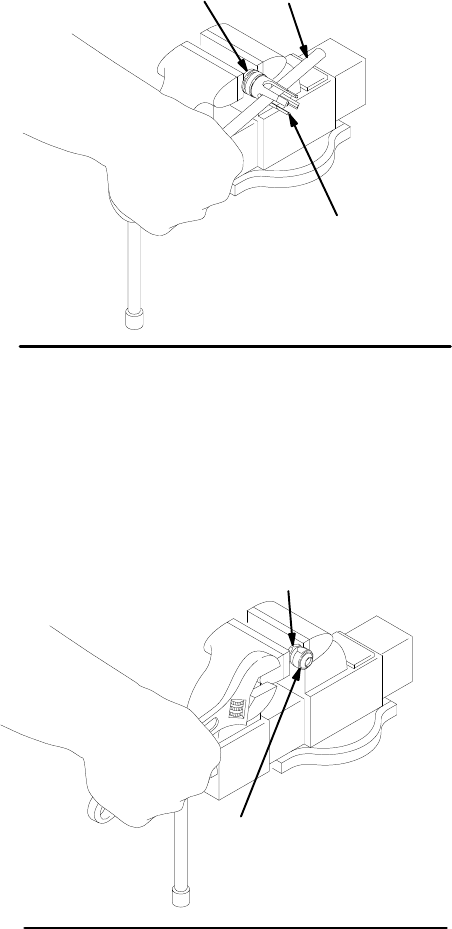

13. Place

the flats of the piston seat (16) in a vise. Using

a

13 mm (1/2 in.) dia. brass rod,

unscrew the piston

guide (14) from the piston seat (16). See Fig 4. Re-

move

the piston seal (15); always replace with a new

one. Inspect the mating surfaces of the piston (13)

and

piston seat (16) for nicks, scoring or wear

.

Fig 4

14

16

BRASS ROD

0205

14. To

disassemble the intake check valve (S), place the

nut

(18) in a vise and unscrew the intake valve body

(19),

using a 28 mm wrench. See Fig 5. Remove the

seals

(42, 20) from the nut and from the valve body;

always

replace them with new ones. Inspect the mat

-

ing surfaces of the intake valve body (19) and seat

(22)

for wear

, scoring, or other damage.

NOTE: The

seal (42) is press-fit in the nut

(18) and may

require

cutting to ease removal.

Fig 5

19

18

0206

15. Inspect all parts for damage and clean with a com-

patible

solvent. T

o reassemble, refer to page 12.