8 308-017

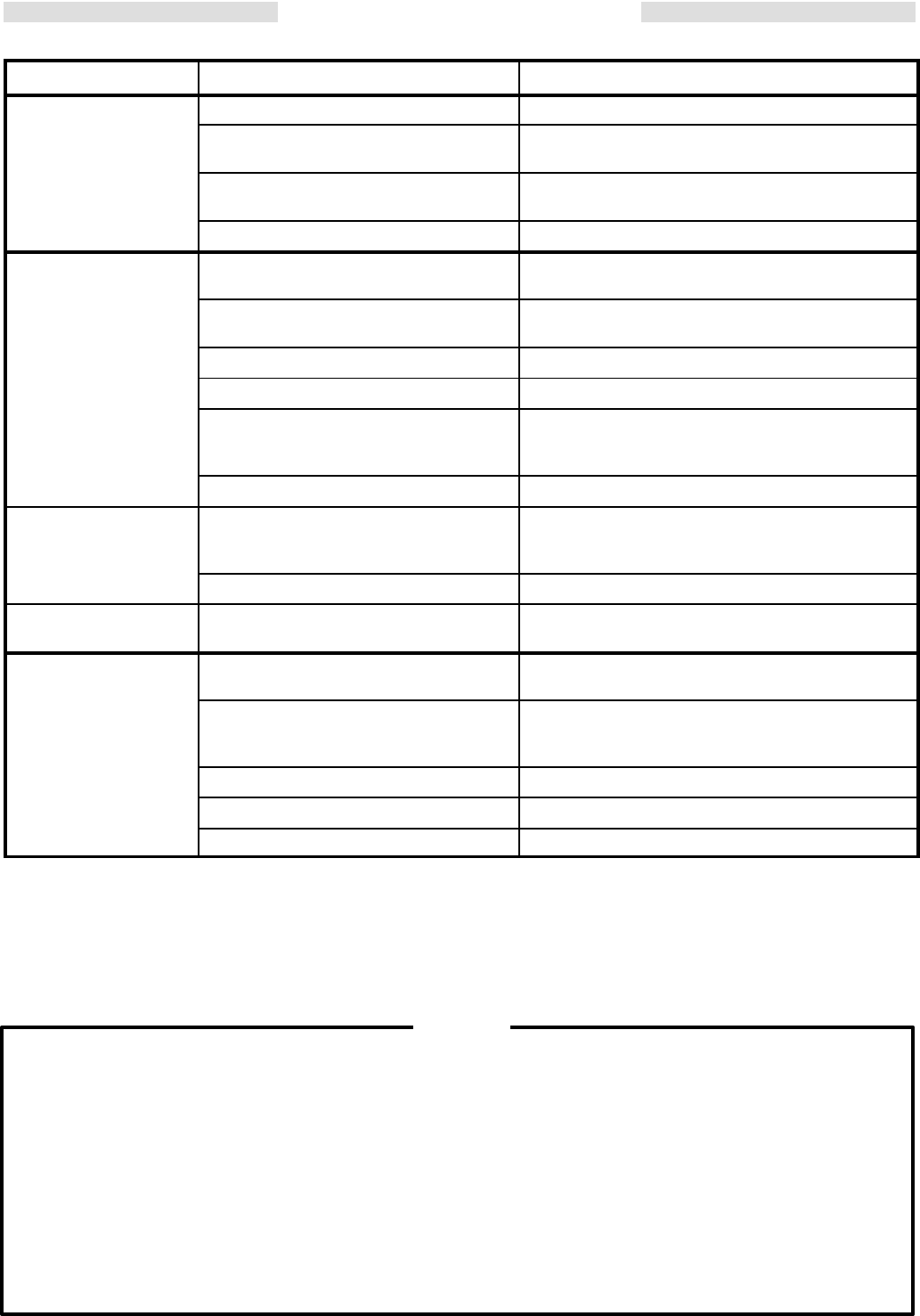

TROUBLESHOOTING

CHART

PROBLEM CAUSE SOLUTION

Pump

fails to operate

Restricted line or inadequate air supply

Clear; see

TECHNICAL DATA

on pages 24-29.

Obstructed fluid hose or gun/valve;

fluid hose ID is too small

Open, clear*; use hose with larger ID.

Fluid dried on the displacement rod

Clean; always stop pump at bottom of stroke;

keep wet-cup 1/3 filled with compatible solvent.

Dirty

, worn, or damaged motor parts

Clean or repair; see air motor manual, supplied.

Pump operates, but out-

put

low on both strokes

Restricted line or inadequate air supply

Clear; see

TECHNICAL DATA

on pages 24-29.

Obstructed fluid hose or gun/valve;

fluid hose ID is too small

Open, clear*; use hose with larger ID.

Bleeder valve open

Close.

Air leaking into supply container

Check wiper plate or ram plate seal.

Fluid too heavy for pump priming

Use bleeder valve (see page 6).

Use inductor or ram.

Remove piston spacer (33).**

W

orn packings in displacement pump

Replace packings.

Pump operates, but out-

put

low on downstroke

Fluid too heavy for pump priming

Use bleeder valve (see page 6).

Use inductor or ram.

Remove piston spacer (33).**

Held open or worn intake valve or seals

Clear valve; replace seals.

Pump operates, but out-

put

low on upstroke

Held open or worn piston valve or seals

Clear valve; replace seals.

Erratic or accelerated

pump

speed

Exhausted fluid supply

Refill and prime.

Fluid too heavy for pump priming

Use bleeder valve (see page 6).

Use inductor or ram.

Remove piston spacer (33).**

Held open or worn piston valve or seals

Clear valve; replace seals.

Held open or worn priming piston

Clear; service.

W

orn packings in displacement pump

Replace packings.

*To

determine if the fluid hose or gun is obstructed, follow the

Pressure Relief Procedure W

arning

below

. Disconnect the fluid hose

and place a

container

at the pump fluid outlet to catch any fluid. T

urn on

the air just enough to start the pump (about 1.4-2.8 bar [20-40 psi]).. If the pump starts

when

the air is turned on, the obstruction is in the fluid hose or gun.

**

Remove the piston spacer (33) only as a last resort, as the pump may not perform well without it.

NOTE:

If you experience air motor icing, call Graco T

echnical Assistance

(1-800-543-0339).

Pressure

Relief Procedure

To

reduce the risk of serious bodily injury

, including fluid injec

-

tion,

splashing in the eyes or on the skin, or injury from mov

-

ing

parts, always follow this

procedure whenever you shut of

f

the

pump, when checking or servicing

any part of the spray/

dispensing system, when installing, cleaning or changing

spray tips/nozzles, and whenever you stop spraying/dis-

pensing.

1. Engage

the spray gun/dispensing valve safety latch.

2.

Shut of

f the air to the pump.

3. Close the bleed-type master air valve (required in your

system).

4. Disengage

the gun/valve safety latch.

5.

Hold a metal part of the gun/valve firmly to the side of a

grounded

metal

pail, and trigger the gun/valve to relieve

pressure.

6. Engage

the gun/valve safety latch.

7. Open

the drain valve (required

in your system) and/or the

pump bleeder valve, having a container ready to catch

the

drainage.

8. Leave

the drain valve open until

you are ready to spray/

dispense

again.

If

you suspect that the spray tip/nozzle or hose is completely

clogged,

or that pressure has not been fully relieved after fol

-

lowing

the steps above,

VER

Y SLOWL

Y loosen the tip guard

retaining nut or hose end coupling and relieve pressure

gradually,

then loosen completely

. Now clear the tip or hose.

WARNING