12 308-017

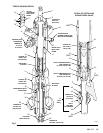

Reassembly (Refer to Fig 7)

1. Place

a 13 mm (1/2 in.) dia. brass rod lengthwise in

a

vise. Install a new piston seal (15*) on the piston

seat.

Apply thread

sealant to the threads of the piston

seat. Place the piston guide (14) securely on the

brass

rod. Using

a 32 mm crow’

s-foot, screw the pis

-

ton seat (16) into the piston guide. Torque to 27-34

N.m (20-25 ft-lb).

2. If

it was necessary to remove the priming piston

rod

(24)

from the piston (13), apply thread sealant to the

threads

of the rod. Place the flats

of the piston (13) in

a

vise. Hold the flats of the rod with a 12 mm

wrench,

and screw the rod into the piston. T orque to 45-53

N.m (33-39 ft-lb).

3. Use

a vise with soft jaws

to hold the displacement rod

(1)

by its flats. Install the spacer (33, see the

follow

-

ing

note) on the rod. Install the

assembled piston gui

-

de/seat on the piston (13). Apply thread sealant to

the threads of the displacement rod, and screw the

piston

assembly onto the rod, using a 19 mm wrench

on the flats of the piston. T orque to 120-130 N.m

(88-95 ft-lb). There will be a small gap between the

top

of the piston (13) and the shoulder of the rod

(1).

NOTE: The piston spacer (33) is not required when

pumping

fluids with a viscosity greater than 1 mil

-

lion

centipoise.

4. Screw the handle of the bleeder valve (35) into the

valve housing. The handle has two sets of threads.

When

reassembling,

be sure to screw the handle ful

-

ly

into the valve housing.

NOTE: It

is not ordinarily necessary to remove the outlet

nipple

(8)

and o-ring (9*). However

, if they were

replaced because of damage, lubricate the o-

ring

(9*) and place it on the nipple (8). Screw the

fitting into the outlet housing (10). T orque to

70-75 N.m (51-55 ft-lb).

5. Lubricate

the o-rings (1

1*) and install them on the

cyl

-

inder (12). Apply thread lubricant to the top threads of

the

cylinder

. Using a 400 mm wrench on the flats of

the cylinder, screw it into the outlet housing (10).

Torque

to 256-297 N.m (190-220 ft-lb).

6. Lubricate

the throat packings and glands, and install

them in the outlet housing (10) one at a time in the

following

order

,

with the lips of the v-packings fac

-

ing down:

male gland (6**), UHMWPE v-packing

(5**),

r

v-packing (3**),

UHMWPE (5**),

(3**),

UHMWPE (5**), and female gland (4**).

Apply

thread lubricant to the packing nut (2) and install the

nut

loosely in the outlet housing.

7. Carefully

insert the displacement

rod (1) into the bot

-

tom

of the cylinder (12). Push the rod up into the cyl

-

inder

and through the outlet housing (10), until it pro

-

trudes from the packing nut (2). Be careful not to

damage the piston seal (15*) while performing this

step.

8. Apply thread lubricant to the bottom threads of the

cylinder (12). Be sure the o-ring (11*) is in place on

the

cylinder

. Guide the intake valve housing (17) up

onto

the priming piston rod (24) and screw it onto the

cylinder, using an adjustable wrench. T orque to

256-297

N.m (190-220 ft-lb).

9. With

the beveled side facing up, press the seal (42)

into the recess of the intake packing nut (18) until it

snaps

into place. The

nose of the seal should be flush

with

or slightly recessed into the face of the packing

nut.

10. Apply

sealant to the threads of the intake packing

nut

(18).

With the threads facing down toward the pump

intake, slide the nut up onto the priming piston rod

(24)

until it clears the flats of the rod.

11. Lubricate a new intake valve seal (20*) and slide it

onto the rod, being careful not to damage the seal

when

passing over the flats of the rod. Slide the seal

up

until it reaches the packing nut (18). Apply

sealant

to the female threads of the intake valve body (19),

and

slide it onto the rod until it reaches the nut (18).

12. Place

a 26 mm wrench on the flats of

the packing nut

(18) and a 28 mm wrench on the flats of the valve

body (19). Screw the nut into the body, making cer-

tain

they remain in position above the flats of the rod

(24).

T

orque to 45-53 N.m (33-39 ft-lb). Slide the as

-

sembled

intake check valve up the priming piston

rod

until

it

reaches the stop (T); this may be dif

ficult due

to

high friction between the seal and rod.

13. Position the intake valve seat (22) so its large bev-

eled

side faces down toward the pump intake.

Slide

the

seat (22) onto the priming piston rod (24) and into

the

intake

valve housing (17) until it seats on the low

-

er

lip of the housing. Lubricate a new seal (21*) and

push

it up into the gap around the bottom outer edge

of

the seat (22).

14. Apply

thread lubricant to the

threads of the intake cyl

-

inder (23) and screw the cylinder into the intake valve

housing

(17), using an adjustable wrench. T

orque to

256-297

N.m (190-220 ft-lb).

15. Slide

the priming piston guide (31) onto

the rod (24)

until

it stops. Then install the priming piston (25) with

the flat side of the priming piston (25) facing up to-

ward

the pump. Apply thread sealant to the threads

of the priming piston rod (24). Hold the rod steady

with a 12 mm wrench on the flats, and screw the

priming piston nut (30) onto the rod with a 22 mm

wrench. T

orque to 45-53 N.m (33-39 ft-lb).

16. Reconnect the displacement pump to the air motor

as

explained on page 9.

17. Allow

2 hours for the thread sealant to cure before re

-

turning

the pump to service.

PTFE

PTFE