28 308-017

TECHNICAL

AND PERFORMANCE DA

T

A (MODEL 222–778)

Ratio 55:1

(Standard Bulldog Air Motor)

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum

fluid working pressure

347 bar (4950 psi)

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum

air input pressure

6.3 bar (90 psi)

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump

cycles per 3.8 liters (1 gal.)

40.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended

pump speed for continuous operation

40 cycles per min

.

. . . . . . . . . . . . . . . .

Maximum

recommended pump speed

60 cycles per min

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum

flow 5.7 liters/min (1.5 gpm) at 60 cycles/min

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air

motor ef

fective diameter

146 mm (5.75”)

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stroke

length

120 mm (4.7”)

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displacement

pump ef

fective area

4.5 cm

@

(0.697 in.

@).

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum

pump operating temperature

65.5_

C (150

_F).

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air

inlet size 3/4 npsm(f)

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid

outlet size

3/4 npt(m)

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weight 45.5

kg (100 lb)

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted

parts

Carbon Steel; E52100, 41L40, and 4140 Alloy Steel; Acetal;

.

. . . . . . . . . . . . . .

304, 316 and 17–4 PH Grades of Stainless Steel; Ductile Iron;

Zinc and Nickel Plating;

r

; Ultra–High Molecular W

eight Polyethylene

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

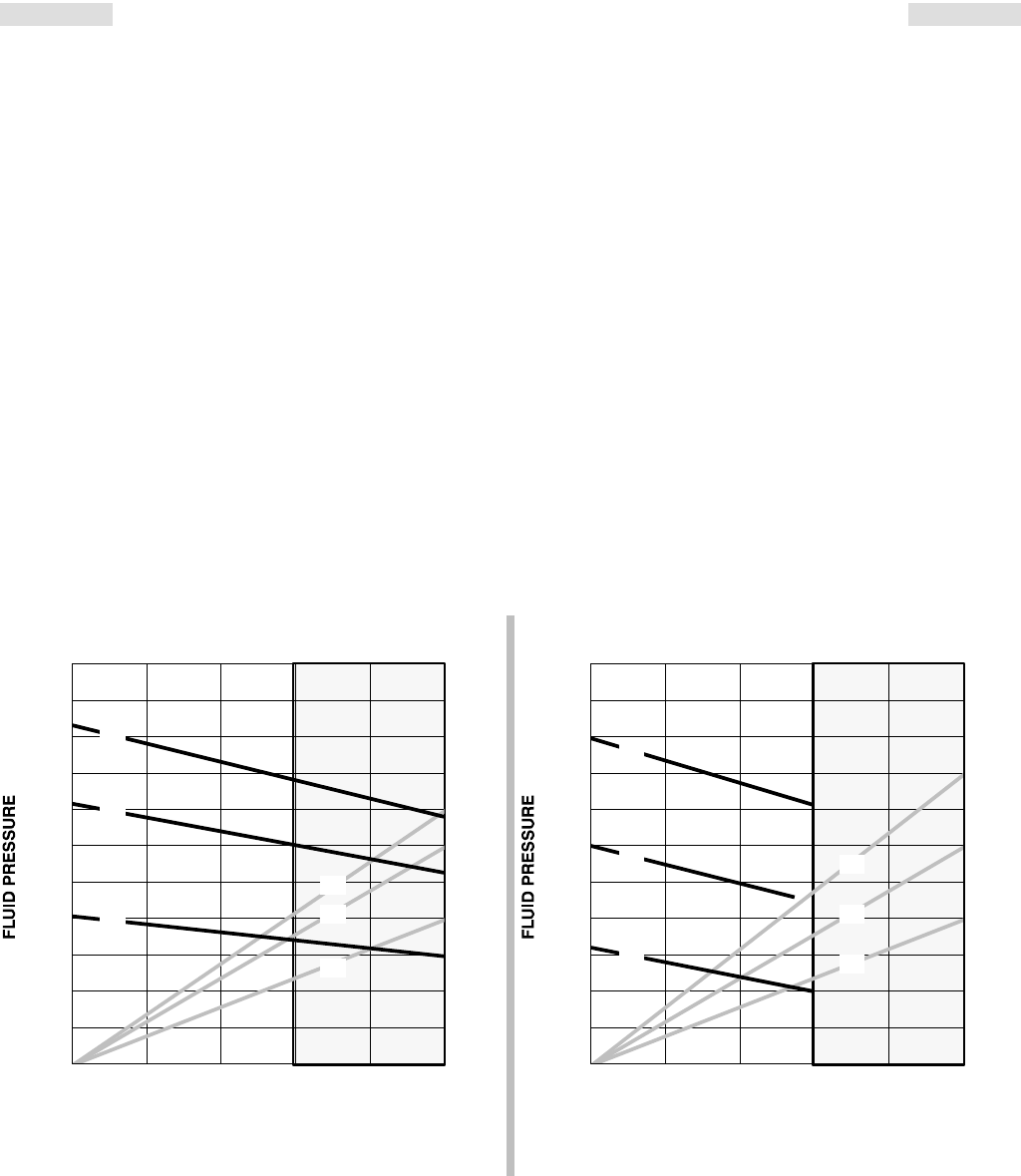

0.0 0.5 1.0 1.5 2.0 2.5

NOTE:

Recommended pump speed for continuous

operation: 40 cpm

Maximum recommended pump speed

(to shaded area): 60 cpm

FLUID FLOW

(TEST FLUID: 1900 CENTIPOISE OIL)

psi

bar

gpm

liters/min

To

find Fluid Outlet Pressure

(bar/psi) at a specific fluid flow

(lpm/gpm)

and

operating air pressure (bar/psi):

1.

Locate desired flow along bottom of chart.

2. Follow

vertical line up to intersection with selected fluid outlet pres

-

sure

curve (black). Follow left to scale to read fluid outlet pressure.

To

find Pump Air Consumption

(m

#

/min or scfm) at a specific fluid flow

(lpm/gpm)

and air pressure (bar/psi):

1.

Locate desired flow along bottom of chart.

2. Read

vertical line up to intersection with

selected air consumption

curve

(gray). Follow right to scale to read air consumption.

cycles/min

scfm

m

#

/min

15

45

60

1.9

315

0.42

1.26

1.68

20

75

2.10

3.8 7.6

35

105

385

60

30

0.84

FLUID FLOW

(TEST FLUID: 100,000 CENTIPOISE SEALANT)

KEY: Fluid Outlet Pressure – Black Curves A

6.3 bar (90 psi) Air Pressure

Air Consumption – Gray Curves B

4.9 bar (70 psi) Air Pressure

C

2.8 bar (40 psi) Air Pressure

A

B

C

A

B

C

70

5.7

40 80

9.5

140

175

210

245

280

350

90

2.52

105

2.94

120

3.36

135

3.78

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

0.0 0.5 1.0 1.5 2.0 2.5

psi

bar

gpm

liters/min

cycles/min

scfm

m

#

/min

15

45

60

1.9

315

0.42

1.26

1.68

20

75

2.10

3.8 7.6

35

105

385

60

30

0.84

A

B

C

A

B

C

70

5.7

40 80

9.5

140

175

210

245

280

350

90

2.52

105

2.94

120

3.36

135

3.78

PTFE

PTFE