6. HF-KN SERIES

6 - 4

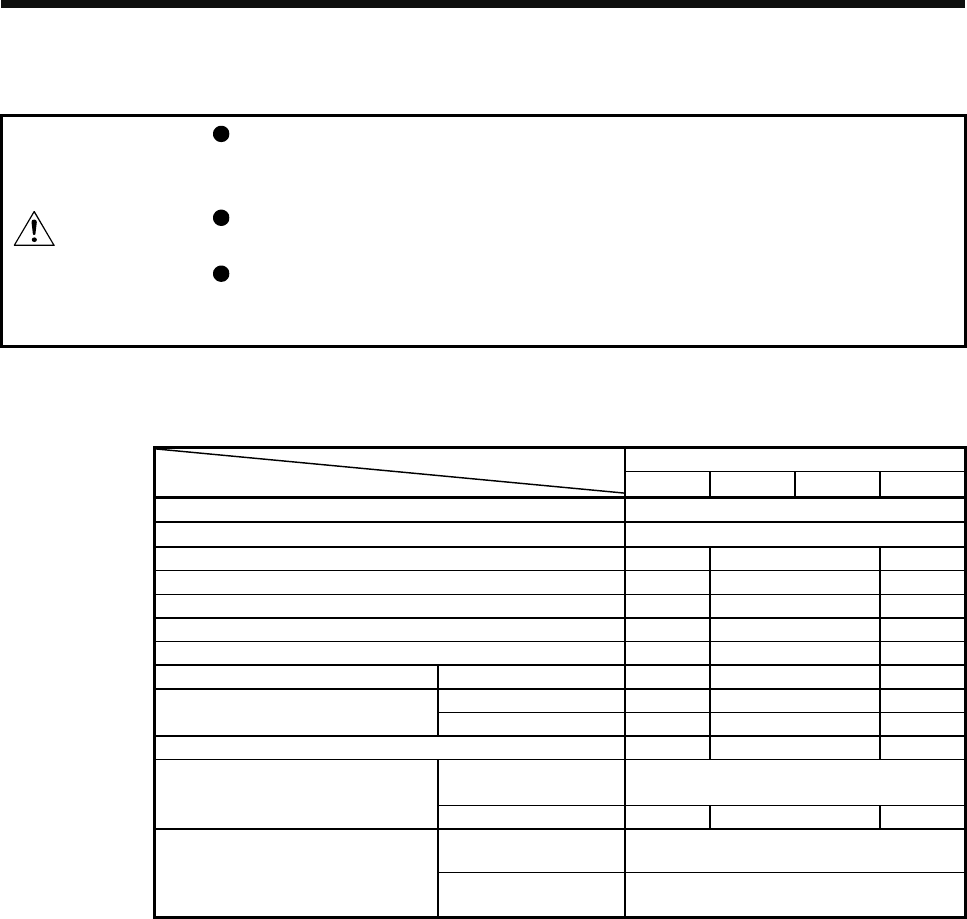

6.4 Electromagnetic brake characteristics

CAUTION

The electromagnetic brake is provided to prevent a drop at a power failure or

servo alarm occurrence during vertical drive or to hold a shaft at a stop. Do not

use it for normal braking (including braking at servo-lock).

Before operating the servo motor, be sure to confirm that the electromagnetic

brake operates properly.

The operation time of the electromagnetic brake differs depending on the power

supply circuit you use. Be sure to check the operation delay time with a real

machine.

The characteristics of the electromagnetic brake provided for the servo motor with an electromagnetic brake

are indicated below.

HF-KN series Servo motor

Item

13B(J) 23B(J) 43B(J) 73BJ

Type (Note 1) Spring actuated type safety brake

Rated voltage (Note 4)

24 V DC

0

-10%

Power consumption [W] at 20 °C 6.3 7.9 10

Coil resistance (Note 6) [Ω] 91.0 73.0 57.0

Inductance (Note 6) [H] 0.15 0.18 0.13

Brake static friction torque [N•m] 0.32 1.3 2.4

Release delay time (Note 2) [s] 0.03 0.03 0.04

Braking delay time (Note 2) [s] DC off 0.01 0.02 0.02

Per braking [J] 5.6 22 64

Permissible braking work

Per hour [J] 56 220 640

Brake looseness at servo motor shaft (Note 5) [degrees] 2.5 1.2 0.9

Number of brakings

[times]

20000

Brake life (Note 3)

Work per braking [J] 5.6 22 64

For the suppressed

voltage 125 V

TND20V-680KB

Selection example of surge absorbers

to be used (Note 7, 8)

For the suppressed

voltage 350 V

TND10V-221KB

Note 1. There is no manual release mechanism. When it is necessary to hand-turn the servo motor shaft for

machine centering, etc., use a separate 24 V DC power supply to release the brake electrically.

2. The value for initial on gap at 20 °C.

3. The brake gap will increase as the brake lining wears, but the gap is not adjustable. The brake life

indicated is the number of braking cycles after which adjustment will be required.

4. Always prepare a power supply exclusively used for the electromagnetic brake.

5. These are initial values. These are not guaranteed values.

6. These values are measured values and not guaranteed values.

7. Select the electromagnetic brake control relay properly, considering the characteristics of the

electromagnetic brake and surge absorber.

8. Manufactured by Nippon Chemi-Con Corporation.