7. Look across the case and gauge tool. The tip of the lever should be even with the bottom

surface of the gauge. If you are re-using the same major parts of the regulator, this

measurement will most likely be correct, and no adjustment will be needed. In fact, bending the

lever should be avoided unless necessary to get the tip of the lever in the proper position.

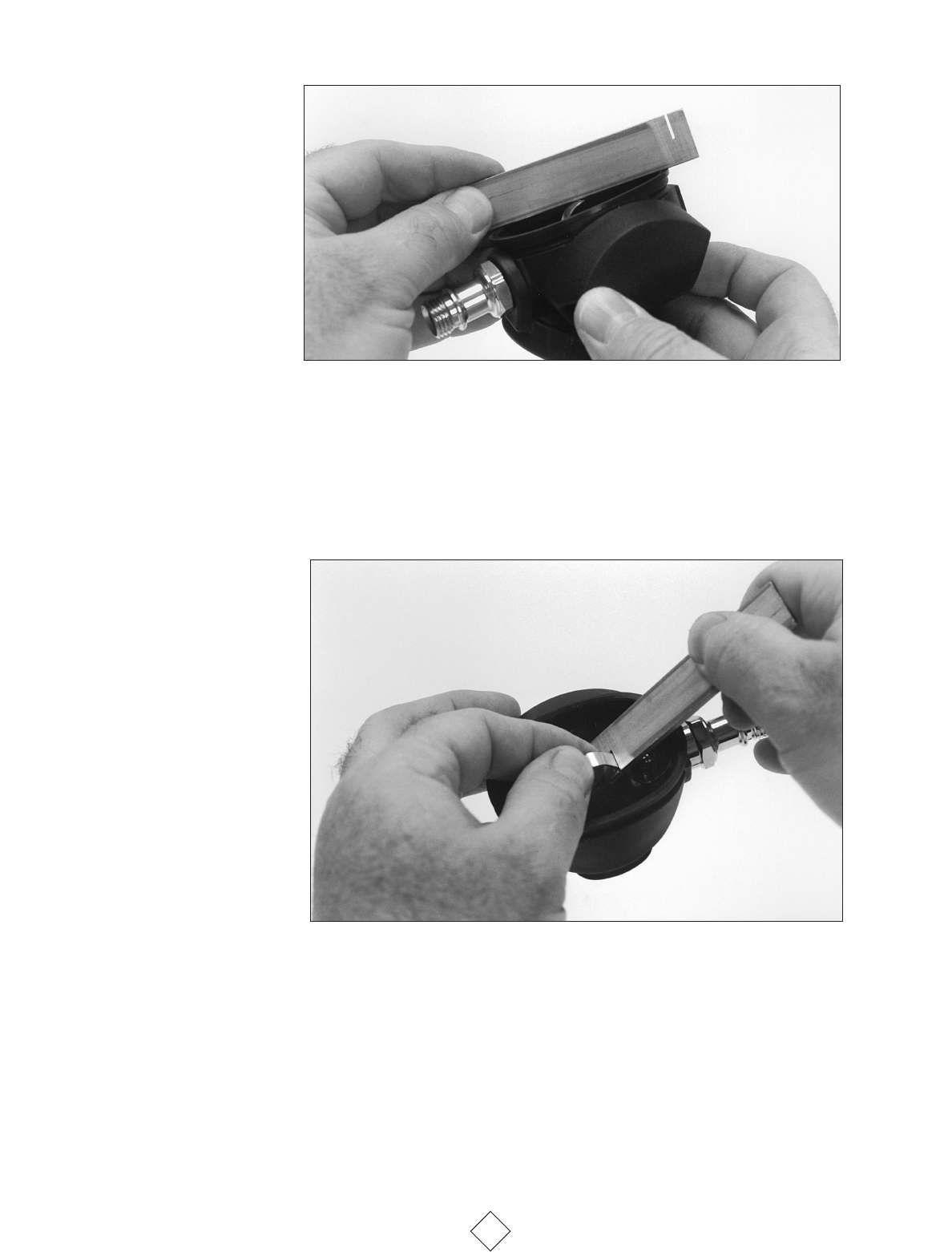

8. If you have installed a new lever, and the lever tip is noticeably high, bend it lower by installing

the lever in the slot of the tool as shown in Photo #5.

9. Holding the tool in one hand, with the tip of the lever toward the fingers, bend the lever

carefully. Do not hold on to the case when making this adjustment, as this can result in the

lever bending at the wrong area (near the lever support instead of at the mid-point of the lever).

If necessary, bend the lever upward using the same holding method. On newer levers there are

two indentations at the proper bend point.

10. After the regulator is assembled, turn on the air. If the regulator hisses slightly, but stops hissing

when the diaphragm is removed, the lever is too high. Use the lever bending tool to bend the

lever slightly downward.

17

Photo #5

Photo #4