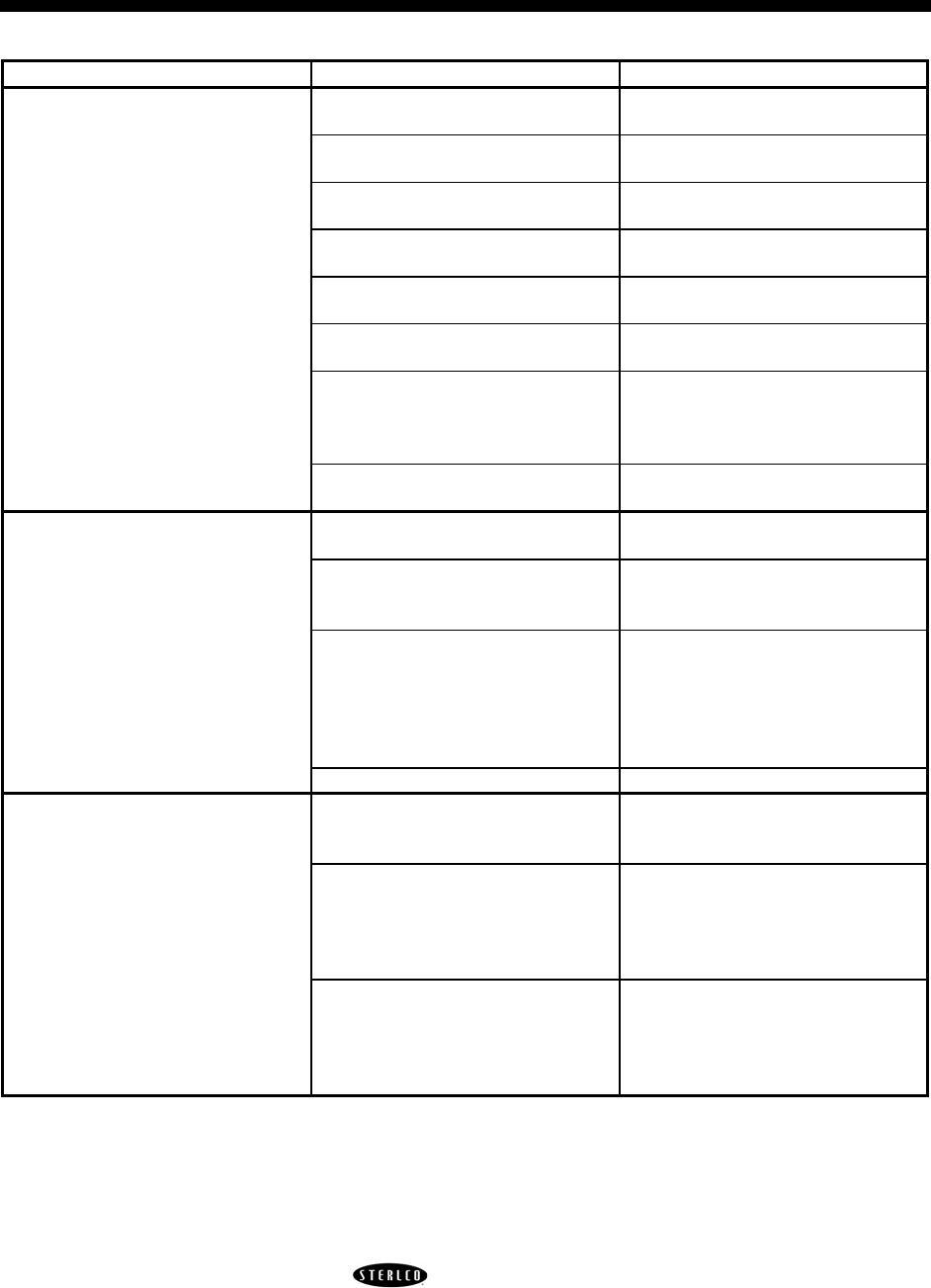

Page 52 6017 Series Hot Oil Large Temperature Control Units

7 Troubleshooting

Condition Possible cause Solution

Undersized connectors/lines.

Increase size of connectors/

water lines.

Long connecting lines between

unit and mold.

Move the unit closer to the mold

and shorten connecting lines.

Serpentine flow through mold.

Connect lines for parallel flow

instead of series flow.

Blocked line in mold.

Check mold for metal chips or

deposits. Clean mold.

Quick disconnect fitting with

check valve.

Remove and replace fitting or

valve.

Carbon build-up in unit piping or

fittings.

Clean or replace affected piping.

Replace fluid.

Faulty Sterlco TCU.

Check unit by opening the

manual bypass to determine if

the TCU contols the set point

temperature.

Temperature fluctuations/rapid

cycling from hot to cold.

Reversed probes.

Switch Return and Delivery

probes.

Loss of fluid in process.

Check all lines/connections/

fittings.

Vent valve open.

Allow vent timer to run out; or,

check valve operation when unit

is cold by opening the fill port.

Faulty/dirty solenoid valve;

usually detected when there is a

steady stream or trickle of water

out of the drain line.

Switch to Manual Cool mode

several times to flush valve. If

the leak continues, disconnect

the power to the unit, turn off the

water supply, and clean or

replace the solenoid.

Unit does not heat properly/can

not achieve set point.

Degraded fluid. Drain and replace fluid.

Defective heater contactor.

Visual inspection of coil and

contacts. Repair/replace

defective contactors.

Defective immersion heater.

Check resistance on all three (3)

legs of heater with an

ohmmeter. If not all equal,

contact factory for replacement

heater.

Unit does not heat.

Heater burnout.

Check heater tank for scorched/

discolored paint. Check

resistance on all three (3) legs

of heater with an ohmmeter.

Replace heater as needed.