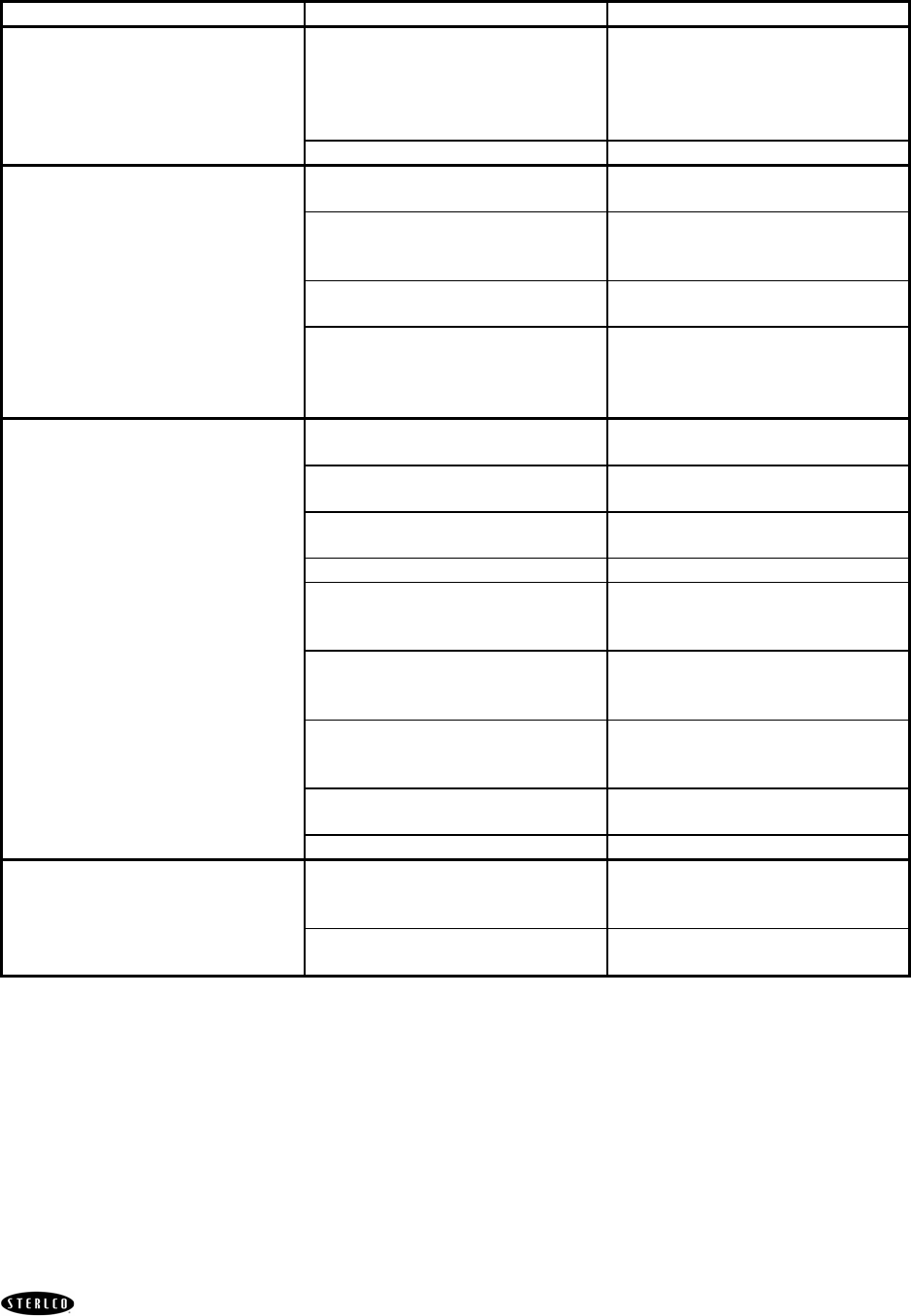

6017 Series Hot Oil Large Temperature Control Units Page 53

Condition Possible cause Solution

Controller heater output open.

Check the heater output with an

ohmmeter to ground. It should

read in the mega-ohm range.

Infinite or zero readings indicate

a defective output.

Unit does not heat.

(cont’d.)

Clogged Y strainer. Clean Y strainer.

Water supply to unit is turned

OFF.

Open water supply.

Water drain is plugged or

excessive back pressure in

drain line.

Clear drain line or eliminate

back pressure condition.

Heat exchanger tubes plugged

by lime deposits.

Remove tube bundles; clean/

replace as required.

Unit overheats/unable to cool.

Faulty solenoid valve.

Test solenoid valve by switching

to Manual Cool mode and listen

for valve operation. Replace if

faulty.

Leaks in connecting lines.

Inspect/replace faulty line or

connection.

Air in circulating lines.

Perform venting sequence in

Chapter 3.

Low fluid.

Check fluid level in sight glass.

Add fluid if required.

Defective Ful-Flo valve. See Chapter 3.

Water in fluid.

Drain water from low point in

piping (see Chapter 3), or boil

water off.

Vent solenoid open.

Allow vent timer to run out; or,

check valve operation when unit

is cold by opening the fill port.

Pump running in reverse.

Check motor; rewire if

necessary. See electrical

diagrams.

Pump repair/adjustment

needed.

Adjust head spacing or replace

worn pump components.

Rapid drop in pressure/no

pressure.

V belt broken/worn. Replace as required.

Water in fluid.

Drain water from low point in

piping (see Chapter 3), or boil

water off.

Noisy pump.

Severely degraded fluid.

Drain and flush system. Replace

fluid.