64

MODEL FCL-1056 SECTION 9.0

TROUBLESHOOTING

9.4.6 Sensor Temperature High or Low

The sensor RTD is most likely miswired.

1. Check wiring connections.

2. Check resistance between RTD in and return leads. The resistance should be close to the values given in

Section 9.10.2.

3. Replace sensor.

9.4.7 Broken Glass Disabled

The impedance of the pH glass electrode is a strong function of temperature. As temperature increases, the glass

impedance decreases. Because the broken glass fault message appears when the glass impedance becomes too

low, it is important that low impedance readings be properly corrected for temperature effects. However, there is a

high temperature cutoff beyond which the correction does not work. Once the temperature exceeds this value, the

broken glass fault is automatically disabled.

This warning should never appear in the FCL-02.

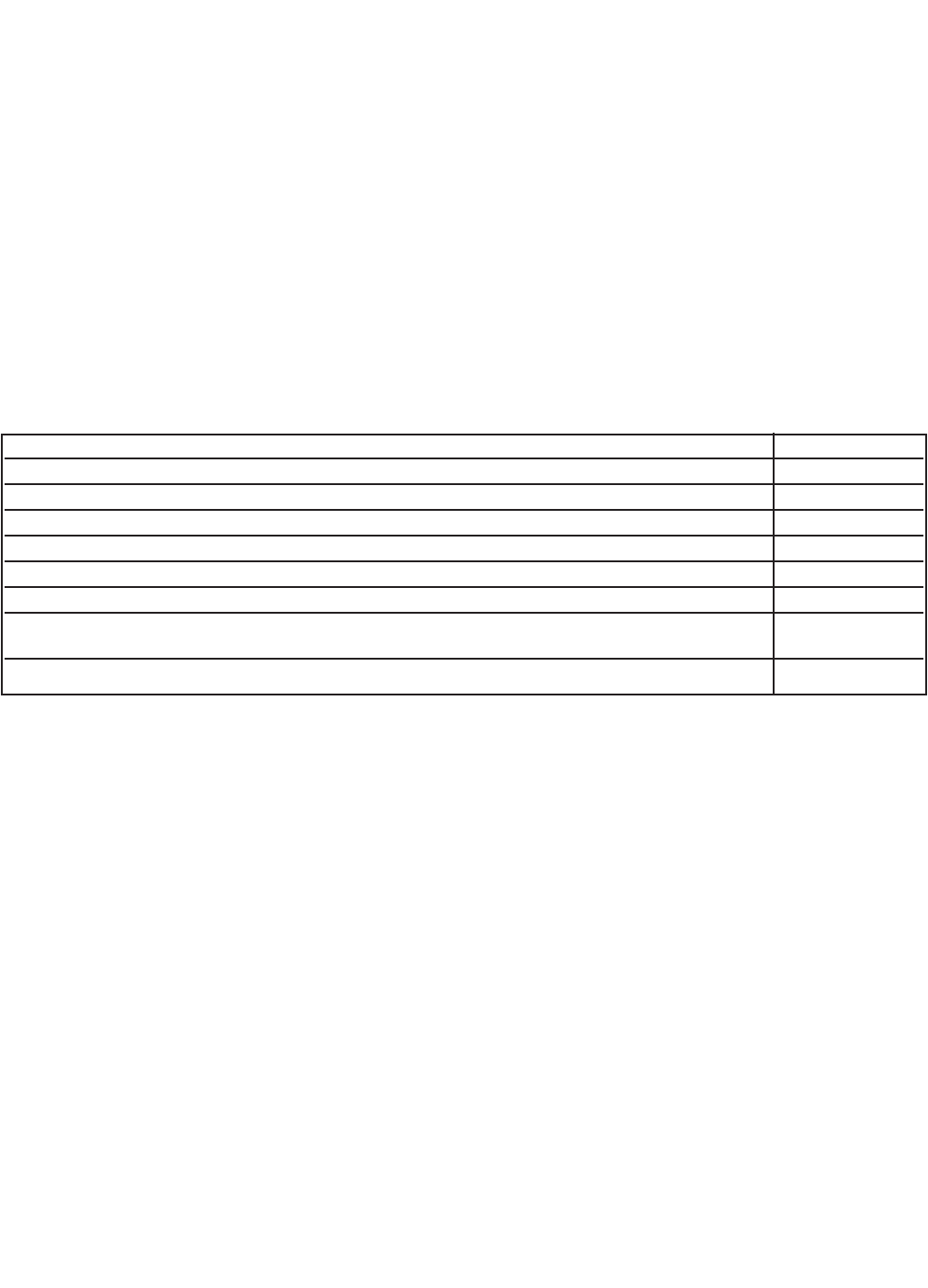

9.5 TROUBLESHOOTING WHEN NO ERROR MESSAGE IS SHOWING — CHLORINE

Problem See Section

Zero current was accepted, but the current is substantially greater than 10 nA 9.5.1

Error or warning message appears while zeroing the sensor (zero current is too high) 9.5.1

Zero current is unstable 9.5.2

Sensor can be calibrated, but sensitivity is significantly different from 350 nA/ppm 9.5.3

Process readings are erratic 9.5.4

Readings drift 9.5.5

Sensor does not respond to changes in chlorine level 9.5.6

Chlorine reading spikes following rapid change in pH 9.5.7

9.5.1 Zero current is too high

1. Is the sensor properly wired to the analyzer? See Section 3.2.

2. Is the zero solution chlorine-free? Take a sample of the solution and test it for free chlorine level. The

concentration should be less than 0.02 ppm.

3. Has adequate time been allowed for the sensor to reach a minimum stable residual current? It may take

several hours, sometimes as long as overnight, for a new sensor to stabilize.

4. Check the membrane for damage and replace it if necessary.

9.5.2 Zero current is unstable

1. Is the sensor properly wired to the analyzer? See Section 3.2. Verify that all wiring connections are tight.

2. Readings are often erratic when a new or rebuilt sensor is first placed in service. Readings usually stabilize

after about an hour.

3. Is the conductivity of the zero solution greater than 50 µS/cm? DO NOT USE DEIONIZED OR DISTILLED

WATER TO ZERO THE SENSOR. The zero solution should contain at least 0.5 grams of sodium chloride per liter.

4. Is the space between the membrane and cathode filled with electrolyte solution and is the flow path between

the electrolyte reservoir and membrane clear? Often the flow of electrolyte can be started by simply holding

the sensor with the membrane end pointing down and sharply shaking the sensor a few times as though shaking

down a clinical thermometer. If shaking does not work, try clearing the holes around the cathode stem. Hold

the sensor with the membrane end pointing up. Unscrew the membrane retainer and remove the membrane

assembly. Be sure the wood ring remains with the membrane assembly. Use the end of a straightened paper

clip to clear the holes at the base of the cathode stem. Replace the membrane.