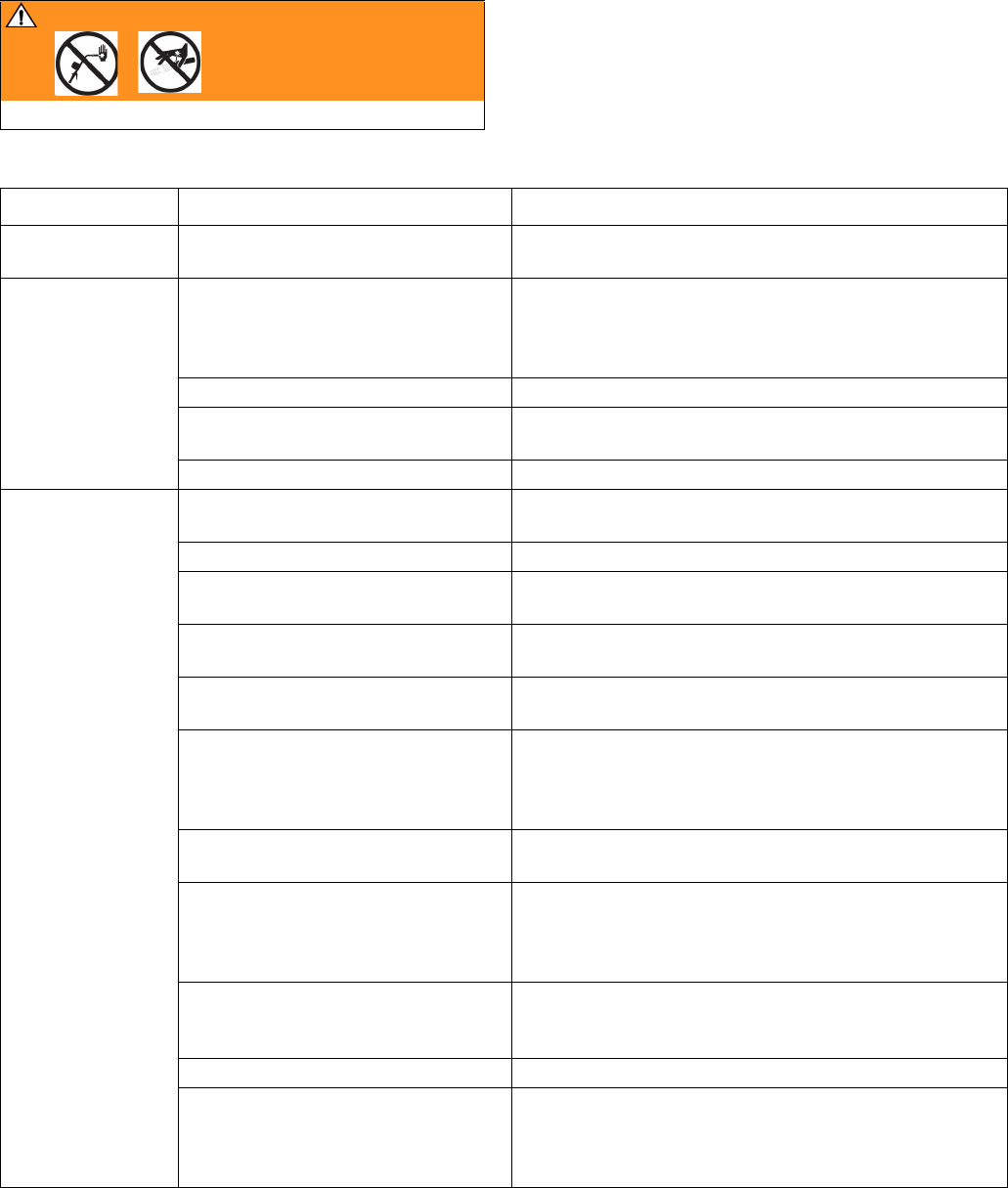

Troubleshooting

16 309497L

Troubleshooting

Relieve pressure before you check or repair the meter.

Follow the Pressure Relief Procedure, page 8.

Be sure all other valves and controls and the pump are

operating properly. If using the chart below to trouble-

shoot is not successful, contact your Graco distributor

for repairs or component replacement.

WARNING

Read warnings, page 3.

Problem Cause Solution

Battery display

bars do not appear.

Battery has low charge. Recharge battery.

Meter display does

not activate.

Battery is dead. Attempt to recharge a dead battery using procedures

outlined in the Battery Charger Instruction Manual

(309502). If procedure does not restore a normal

charge, replace the battery.

Battery inserted too soon. Wait 30 seconds and reinstall fully charged battery.

Cable connections are loose or dis-

connected.

Ensure cables are properly connected. See page 22.

Electronic display is damaged.

Replace with Bezel Repair Kit (246438). See page 33.

Slow or no fluid

flow from meter.

CleanLine filter system is clogged. Clean or replace the CleanLine filter. Refer to the Clean-

Line Filter System Instruction Manual (310652).

Meter is not in dispense mode. See dispense options, page 14.

Matrix meter filter is clogged. Clean or replace the Matrix meter filter element. See

Cleaning or Replacing the FIlter page 21.

Pump pressure is low. Turn up air pressure to the pump. SeeTechnical Speci-

fications page 35.

Pump or reel fluid shut-off valve is

not fully open.

Fully open pump or reel fluid shut-off valve.

Meter hydraulic valve is not function-

ing.

If meter bars are lit indicating flow, the nozzle tip is fully

open, and the fluid flow has been verified to the meter

valve inlet, then the meter hydraulic valve has failed and

the meter should be replaced.

Electronic board connections may be

loose or disconnected.

Verify that all connectors are connected or re-seated to

the board connections. See page 22.

Trigger membrane switch is dam-

aged - flow bars DO NOT show on

the meter display when the trigger IS

actuated.

Replace the trigger membrane using the Trigger Repair

Kit (246439 N. A., 249883 Australia). See page 33.

Meter valve is blocked with debris -

flow bars DO show on the meter dis-

play when trigger IS actuated.

Flush the valve with mineral spirits at high pressure and

flow. Warning: do not exceed the maximum working

pressure of the meter (1500psi - 103 bar).

Quick close nozzle is closed. Open nozzle, see F

IG. 21 on page 15.

A hydraulic quick disconnect was

used to connect the meter to the dis-

pense hose, allowing debris to clog

meter.

Quick disconnects should not be used with Matrix prod-

uct, doing so voids the warranty.