10. While pressing firmly onto the inflator

body, turn the black locking ring

clockwise to the locked position, and

pull on the inflator cap to ensure

it is locked onto the inflator body

(Figure 14).

11. Ensure that the status indicator on the

new inflator cap is green, the pull-

to-inflate lanyard is present, and the

locking ring is locked.

12. To test for leakage, inflate the LP

using the oral inflator tube – see Inflating. To avoid damage to the LP

do not use a compressor (the maximum pressure should not exceed 2

psi). After two hours there should be no noticeable drop in pressure in

the LP.

13. Deflate and repack the LP – see Deflating, and Repacking.

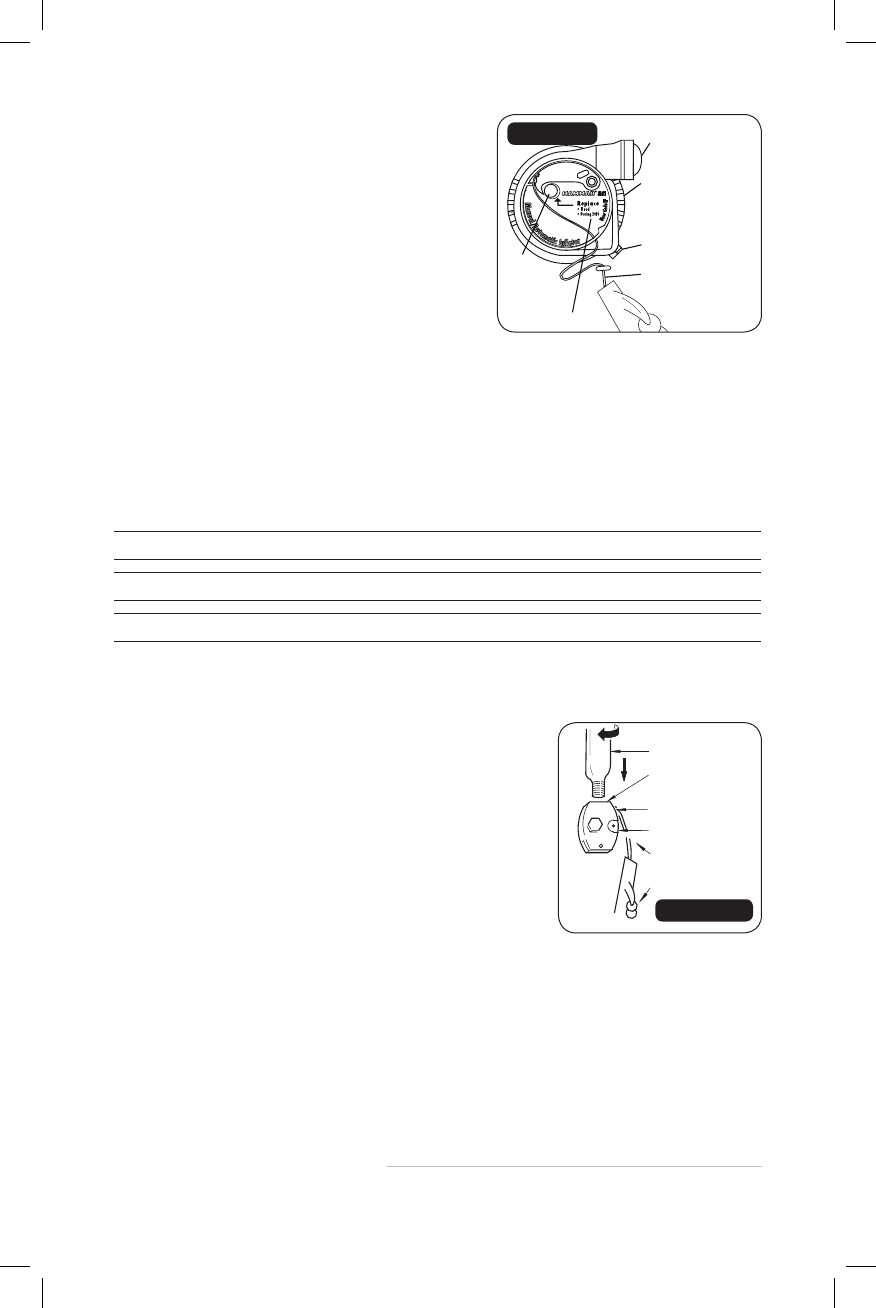

RE-ARMING THE MD3091

CAUTION: The LP must be deflated before being re-armed.

NOTE: An MA7170 re-arming kit is required for this procedure.

CAUTION: Follow the steps below in the exact sequence described.

1. Unscrew and discard the CO

2

cylinder (Figure 15).

2. Ensure the manual lever is in the up and ready position and the manual

inflator mechanism status pin is properly

installed. If missing or damaged, replace the

status pin (Figure 15).

3. To install the new CO

2

cylinder, screw it into

the top of the inflator and hand-tighten. To

avoid damage to the internal gasket, do not

over-tighten (Figure 15).

4. To test for leakage, inflate the LP using the

oral inflator tube – see Inflating. To avoid

damage to the LP do not use a compressor

(the maximum pressure should not exceed

2 psi). After two hours there should be no

noticeable drop in pressure in the LP.

5. Deflate and repack the LP – see Deflating, and Repacking.

Status

Indicator

Hydrostatic Water

Inlet Valve

Manual Ination

Lanyard

Beaded Manual

Ination Handle

Tabs

Black Locking Ring

Expiry Date

FiGURE 14

CO2 Cylinder

Inator Mechanism

Up-and-Ready

Status Pin

Ination Lanyard

Beaded Manual

Ination Handle

FiGURE 15

Compact Tactical LP Owners Manual

7