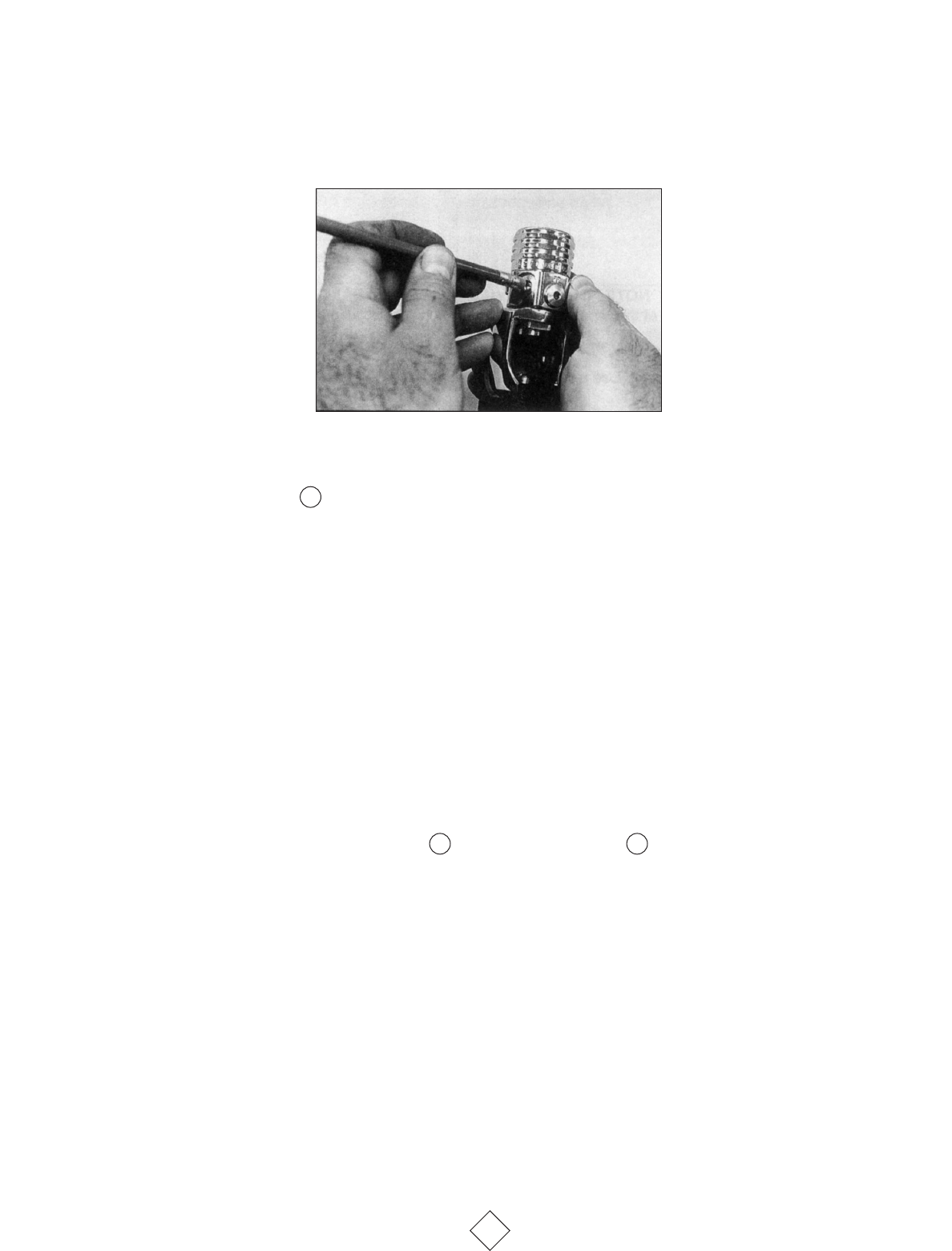

The sealing surface on the body where the one-way valve seals must be totally clean of

deposits. If any deposits remain on the sealing surface after initial cleaning, take a

fine abrasive

polishing stick or a pencil with a new eraser and polish the surface to remove deposits (see

Photo #3).

13. Blow all residue from the body after polishing.

14. Remove the large O-ring from the body. This O-ring can usually be reused.

15. If necessary, clean all metal parts of the first stage

except piston in an ultrasonic cleaner or

cleaning solution. Remove the O-rings before cleaning any metal parts; most cleaning

solutions can damage the O-ring material. See Section 6.3 for recommendations on cleaning

solutions. If major visible corrosion or deposits exist on parts, use a bristle brush, wooden, or

plastic stick to rub the deposits off. Allowing acidic cleaning solutions to do all of the work if

deposits are severe, will result in damage to internal chrome plating which will make parts even

more susceptible to future corrosion.

16. Remove the regulator parts from the cleaning solution. Blow all internal passageways dry with

clean, dry compressed air.

17. Inspect the bores in which the piston and orifice O-rings move for corrosion or wear. If the

bores are leaking air because of wear, replace the parts. If some corrosion deposits persist,

carefully wipe them away with a plastic scrubbing cloth. Blow any resulting dust out of the

regulator parts.

18. Remove and discard the two black O-rings from the moving orifice . Save the white

backup washer; it can be reused. Inspect the moving orifice’s sealing surface (located at the

top edge of the orifice cone). Any nicks, scratches, or corrosion at the top of the cone can

allow air to pass, which will result in creeping hose pressures. Polish out the defects using a

fine abrasive polishing stick or pencil eraser. When polishing, apply a light pressure to prevent

excessive wear on the cone. Use compressed air to blow away any dust created by the

polishing process. You do not have to polish or smooth the relatively rough lower/outer edge of

the orifice cone. This is not a sealing surface.

8

Photo #3

18

4

7