Series 830/840/860 Instruction Manual Chapter 1 Introduction

IM-83/84/86-H 1-5

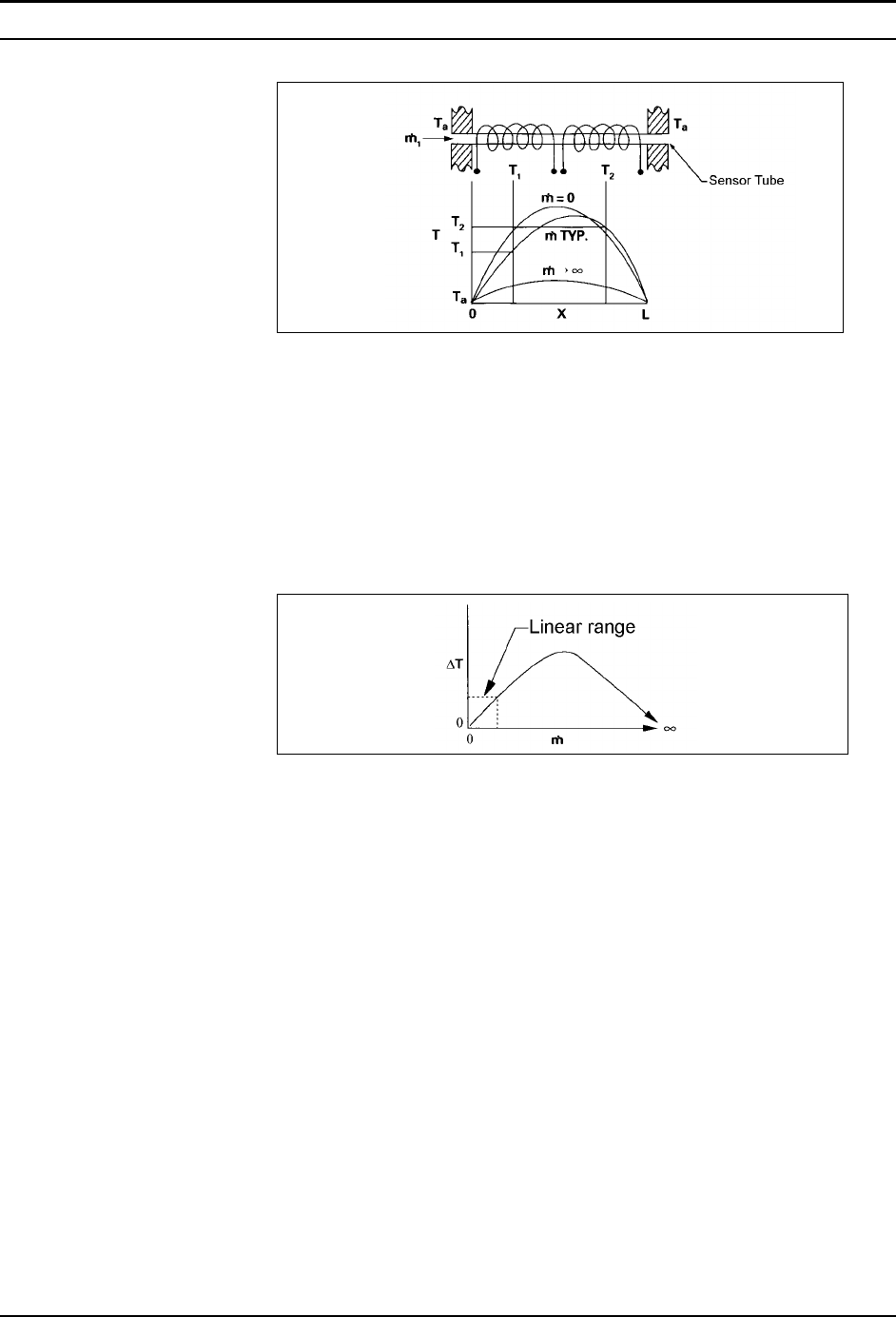

Figure 1-3. Sensor Temperature Distribution

Figures 1-2 and 1-3 show the mass flow through the sensor tube as

inversely proportional to the temperature difference of the coils. The

coils are legs of a bridge circuit with an output voltage in direct pro-

portion to the difference in the coils’ resistance; the result is the tem-

perature difference (∆T). Two other parameters, heat input (H) and

coefficient of specific heat (Cp) are both constant. The resulting out-

put is nearly linear over the transducer’s normal operating range.

Figure 1-4. Linear Range of the Transducer’s Output Signal

For mass flow controllers, once the gas flows through the monitor-

ing section, it is then controlled by the built-in servo-control valve.

For flows up to 500 slpm, Sierra’s proprietary high-efficiency Fast-

Trak Electromagnetic Valve is used. The normally closed Fast-

Trak valve is similar to an on/off solenoid valve, except that the

current to the valve coil, and hence the magnetic field, is modu-

lated so that the ferromagnetic valve armature, or valve plug, as-

sumes the exact height above the valve’s orifice required to main-

tain the valve’s command flow. The result is nearly infinite resolu-

tion. All controllers with the Fast-Trak valves are available with a

“Soft-Start” option for those processes that require it.

For higher flows of 50 to 200 scfm, controllers are equipped with Si-

erra’s microprocessor-controlled, motor-operated rotary valve. While

the rotary valve does not provide a completely positive shut-off, it

does offer accurate control for higher flow installations.