Chapter 4 Maintenance Series 830/840/860 Instruction Manual

4-6 IM-83/84/86-H

Sensor Maintenance

The sensor tube is straight and has a relatively large, 0.031 inch

ID, which makes inspection and cleaning easy. Sensor mainte-

nance consists of:

• inspecting and cleaning the sensor flow path

• checking the sensor for proper electrical function

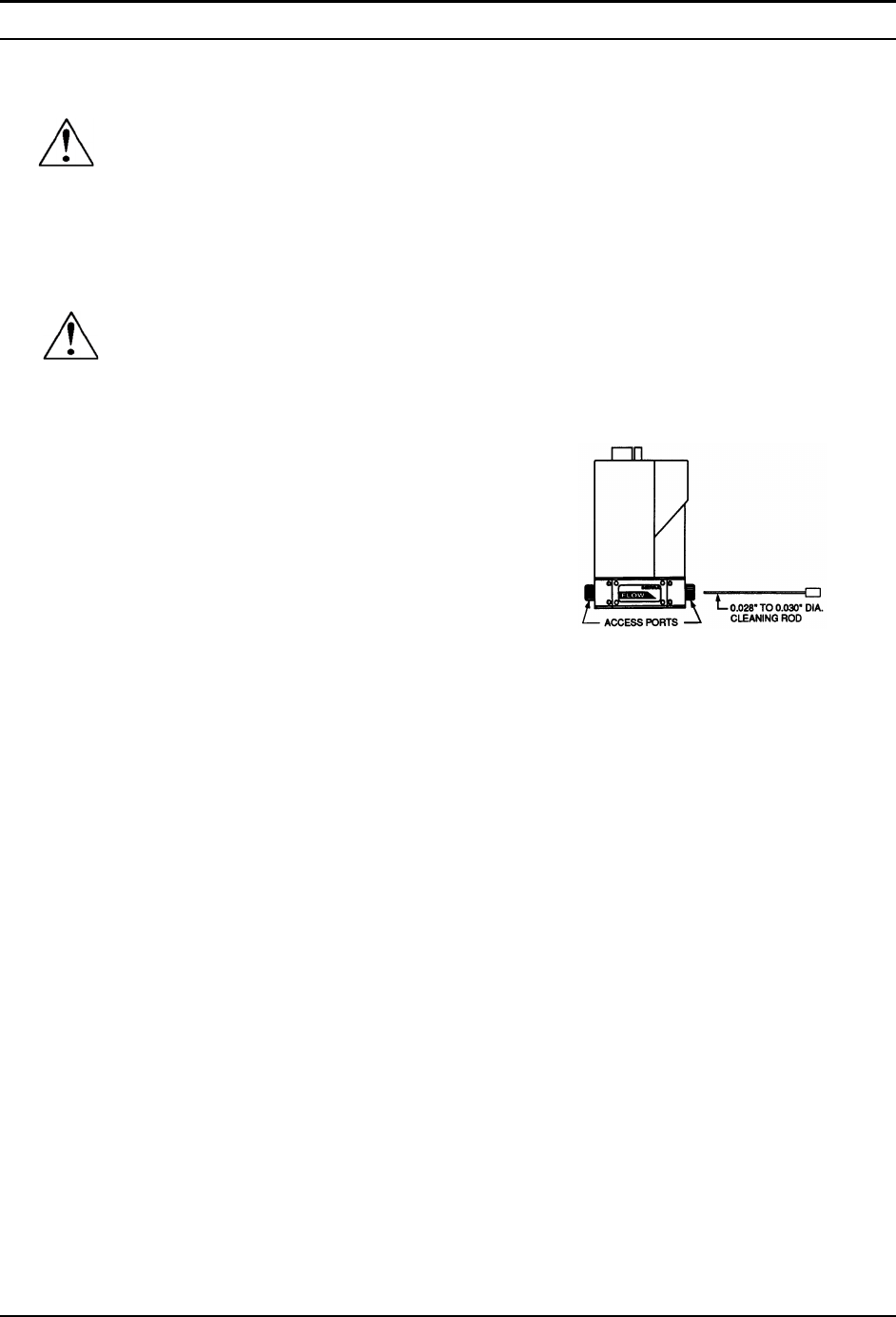

Sensor Cleaning and Inspection

Cleaning is accomplished by simply rodding out the sensor with

the Sensor Cleaning Stylette, part number “CK”, available from

Sierra for this purpose. (A 0.020 inch to 0.028 inch diameter piano

wire may also be used.) To access the sensor for inspection or

cleaning:

1. Remove the unit from the system.

2. Remove the two socket head ac-

cess port plugs with a 1/4 inch

Allen wrench.

3. Visually inspect the sensing ports

and sensor.

4. Use a hemostat or tweezers to push the cleaning wire into the

downstream opening of the sensor tube. Do not force the clean-

ing wire; move it back and forth–DO NOT TWIST OR

ROTATE.

5. Flush the sensor tube with a non-residuous solvent. In cases

where solids are deposited in sensor, units should be returned

to factory for complete cleaning and re-calibration.

6. Blow dry all parts with dry nitrogen and re-assemble.

7. When the transducer is re-installed in the system, leak test the

connection.

8. Check transducer calibration.

Caution!

Do not remove the sen-

sor cover, this could shift

transducer calibration.

Caution!

When using toxic or cor-

rosive gases, purge the

unit thoroughly with inert

dry gas before discon-

necting from the gas line.