26

TT

TT

AA

AA

KK

KK

II

II

NN

NN

GG

GG

CC

CC

AA

AA

RR

RR

EE

EE

OO

OO

FF

FF

YY

YY

OO

OO

UU

UU

RR

RR

TT

TT

RR

RR

EE

EE

AA

AA

DD

DD

MM

MM

II

II

LL

LL

LL

LL

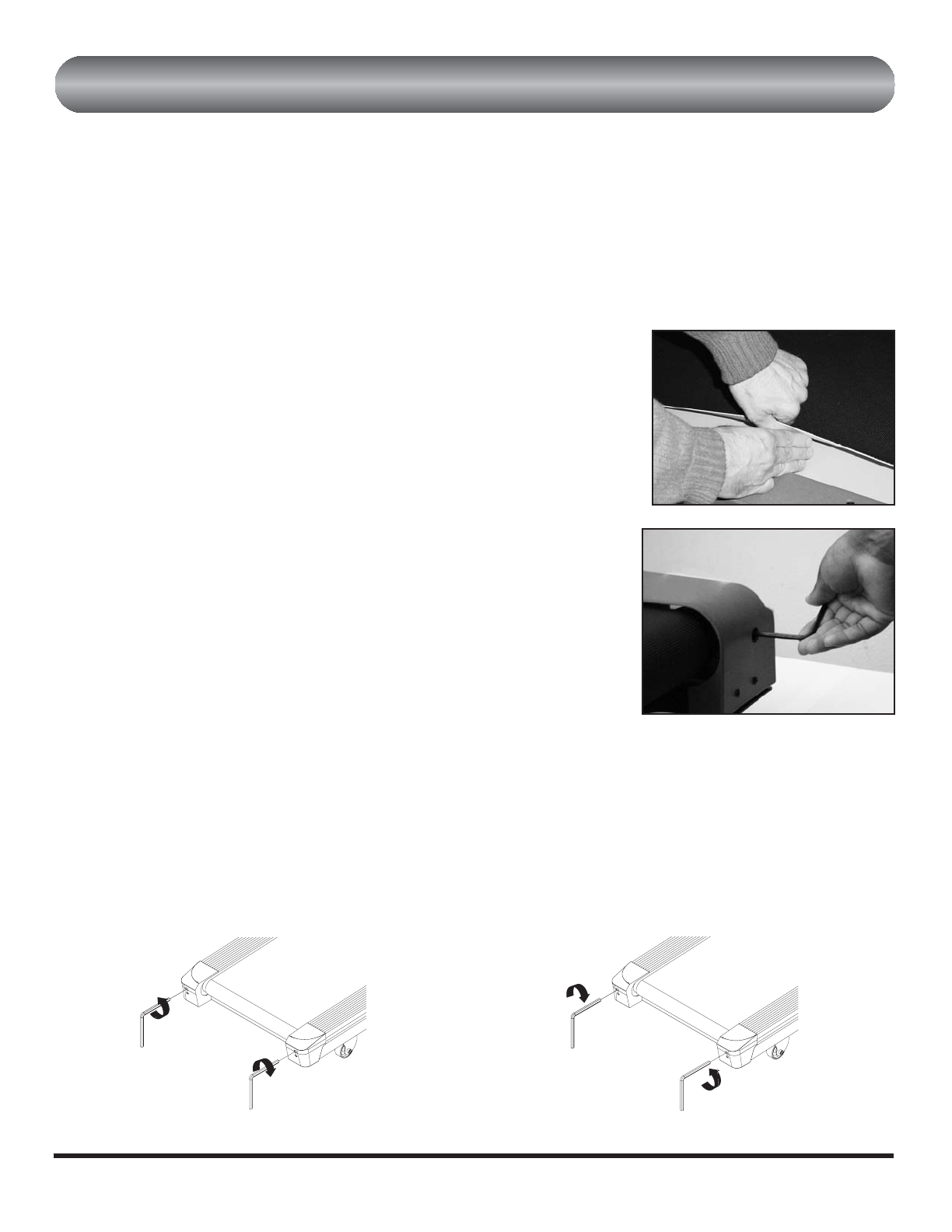

Just like changing the oil in your car or replacing a filter in your home’s heating and cooling system, a little

preventive maintenance will insure your treadmill will operate smoothly and quietly for years to come.

WALKING BELT TENSION

As walking belts tend to stretch slightly with use, the walking belt may occasionally need to be tightened. If

the walking belt is too loose, you may find the belt stops while running or walking, while the motor contin-

ues to run. DO NOT OVERTIGHTEN THE BELT. This will cause reduced motor performance and roller

damage.

When properly tensioned, you should be able to lift the side of the belt about

2-3 inches (5-7.5 centimeters). A quick test for belt tension: you should be

able to fit three fingers under the edge of the belt.

To tighten belt:

Use the hex key provided with the treadmill (or a 3/16 inch hex wrench).

Place the hex key in the hole in left end cap and into the socket of the

adjustment screw. Turn key one full turn clockwise. Then place hex key in

hole in right end cap and turn key one full turn clockwise. Check the ten-

sion of the belt. Continue back and forth until belt is at the correct tension.

Make sure to adjust both sides equally to ensure correct belt alignment.

WALKING BELT CENTERING

The walking belt may occasionally need to be centered.

First be certain that belt is tensioned properly (see above).

Run the treadmill at about 3.5 mph (6 kph)

Place the hex key through the hole in the left end cap and into the socket of the adjustment screw.

If belt has moved to the right:

Turn the right adjustment screw 1/2 turn clock-

wise, then turn the left adjustment screw 1/2 turn

counterclockwise.

If belt does not move, repeat until belt is centered.

If the belt has moved to the left:

Turn the right adjustment screw 1/2 turn counter-

clockwise, then turn the left adjustment screw 1/2

turn clockwise.

If belt does not move, repeat until belt is centered.

Then recheck tension of the belt (see above).

1/2 TURNS

THEN RECHECK TENSION OF THE BELT

UNTIL BELT IS CENTERED

1/2 TURNS

THEN RECHECK TENSION OF THE BELT

UNTIL BELT IS CENTERED