32

4. Repeat step 1 to ensure that the

angle of the sensor is correct.

Note: Do not position the sensor

farther into the water than necessary

to avoid increasing drag, spray, and

water noise and reducing boat

speed.

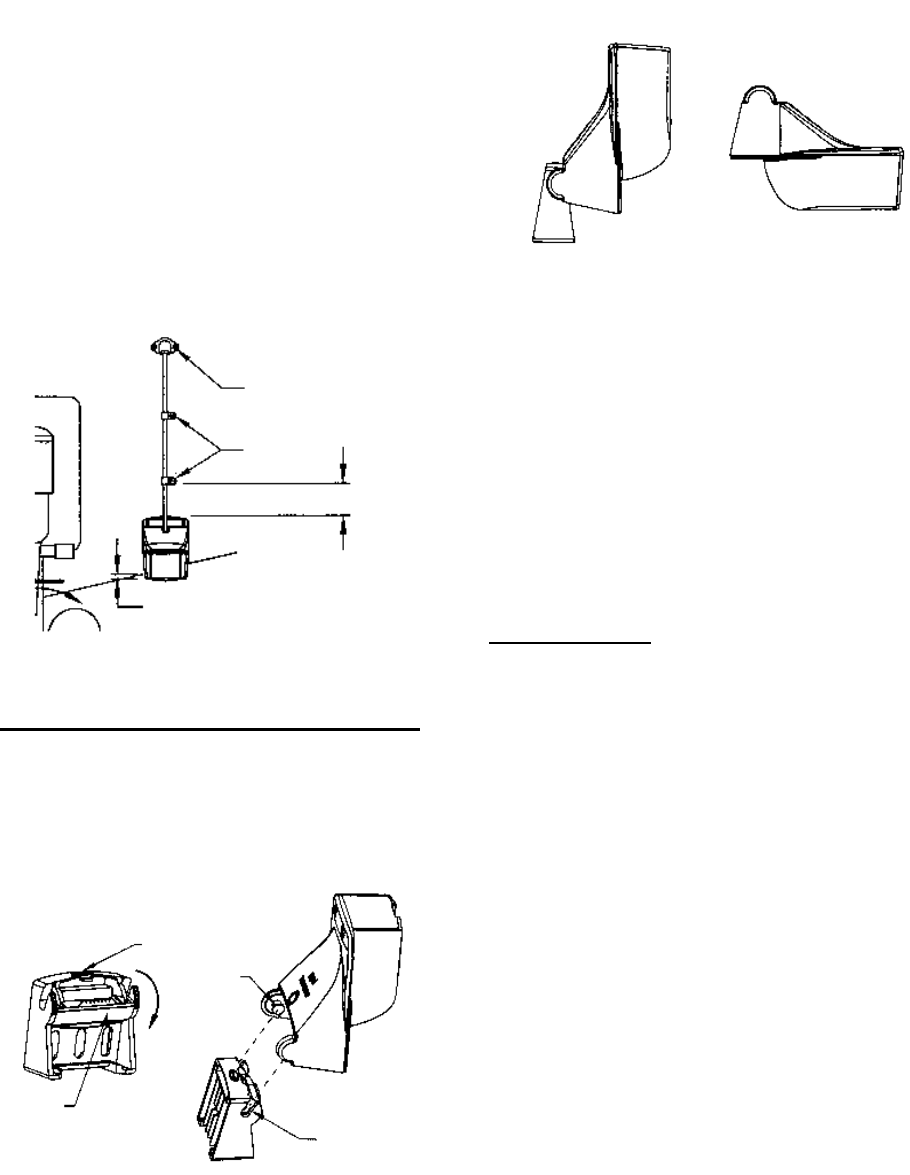

5. Using the vertical adjustment space

on the bracket slots, slide the sensor

up or down to provide a projection of

3 mm (1/8”). Tighten the screws.

Cable cover

Cable

clamp

50 mm (2")

Hull projection 3 mm (1/8")

Vertical adjustment and cable routing

Attaching the sensor to the bracket

1. If the retaining cover near the top of

the bracket is closed, open it by

depressing the latch and rotating the

cover downward.

Step 1 Step 2

Latch

Retaining

cover

Pivot

arm (2)

Slot (2)

Step 4

Step 3

Attaching the sensor to the bracket

2. Insert the sensor’s pivot arms into

the slots near the top of the bracket.

3. Maintain pressure until the pivot

arms click into place.

4. Rotate the sensor downward until the

bottom snaps into the bracket.

5. Close the retaining cover to prevent

the accidental release of the sensor

when the boat is underway.

Cable routing

Route the sensor cable over the

transom, through a drain hole, or

thorough a new hole drilled in the

transom above the waterline.

Never cut the cable or remote the

connector; this will void the warranty.

Always wear safety goggles and a dust

mask.

1. If a hole must be drilled, choose a

location well above the waterline.

Check for obstructions such as trim

tabs, pumps, or wiring inside the hull.

Mark the location with a pencil. Drill

a hole through the transom using a

19 mm or 3/4” bit (to accommodate

the connector).

2. Route the cable over or through the

transom.

3. On the outside of the hull secure the

cable against the transom using the

cable clamps. Position a cable clamp

50 mm(2”) above the bracket and

mark the mounting hole with a

pencil.