Installation

312964C 9

Installation

1. Remove the bung fitting and screw in the TLM

hand-tight. DO NOT use a wrench to tighten as this

may damage the TLM. Do not use thread lock adhe-

sive as this may damage the TLM.

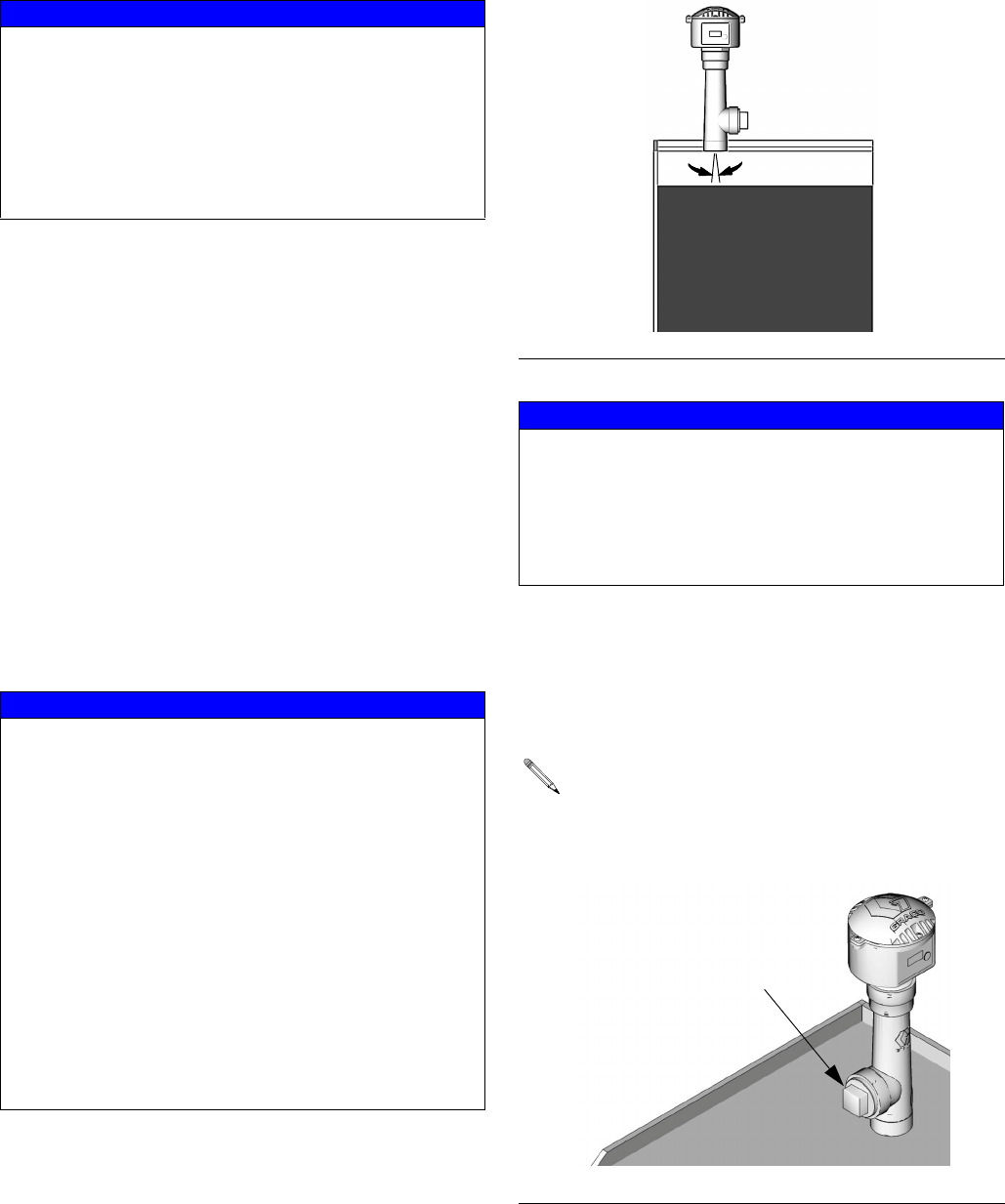

2. The TLM must be mounted within 2 degrees from

perpendicular to the surface of the fluid. A level that

measures degrees should be used. Place the level

on the top of the pipe fitting on the tank. If outside

the 2 degree specification, the fitting should be

changed.

Graco recommends that the height of the tank fitting

should not exceed 1/2 in. (1.27 cm). The fitting

height can be up to 2 in. (5.08 cm), provided the fit-

ting is within 2 degrees of the surface of the fluid.

Also, the taller the tank, the more critical the 2

degree specification becomes. See F

IG. 6.

The tank’s breather port might be the only available

location for mounting the TLM. The horizontal 2 in. npt

port (D) can be used to accommodate the breather. The

breather should be mounted in an upright position using

a 90° elbow fitting.

NOTICE

• Do not over tighten tank level monitor into tank

bung! Over tightening can cause permanent dam-

age and result in inaccurate readings.

• Do not use thread sealant or adhesive! Many of

these products are chemically incompatible with the

PC/ABS plastic.

• Use the Graco-supplied down tube 15U731 only. Do

not replace down tube with any other tube.

NOTICE

• The TLM will not operate correctly if tilted more than

2° from the surface of the tank liquid.

• The TLM will not read properly if:

- Fluid in the tank is agitated (i.e. filling a tank

with oil or anti-freeze). Be sure to take all TLM

readings when the fluid in the tank is calm.

- TLM is mounted next to the tank wall or in a cor-

ner.

- If there is any structural bracing or obstruction

between the TLM and the surface of fluid in

tank.

- If the down tube is not the Graco-supplied down

tube.

FIG. 6

NOTICE

Do not install the TLM in the tank’s fill port. Repeated

removal of the TLM will damage the unit and void the

warranty.

Port (D) is not to be used as a fill hole for oil deliveries.

See F

IG. 7.

Do not use the horizontal port for routing pressure

relief return tubes. This can result in inaccurate

readings.

F

IG. 7

2°

2°

TLM must be mounted with-

in 2° from perpendicular to

the surface of the fluid.

D

ti12034a