14 308639

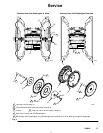

Service

Ball Check Valve Repair

Tools Required

D Torque wrench

D 15-mm socket wrench

D O-ring pick

NOTE: A Fluid Section Service Kit is available. See

the Repair Kit Matrix on page 21 to find the correct kit

for your pump. Parts included in the kit are marked

with an asterisk in the Parts Drawing on page 22, for

example (201*). Use all the parts in the kit for the best

results.

NOTE: To ensure proper seating of the balls (201),

always replace the seats (101) when you replace the

balls.

Disassembly (See Fig. 6)

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 9.

WARNING

Some of the pump parts and assemblies are heavy.

Use proper lifting equipment and techniques.

2. Using a 15-mm socket wrench, remove the bolts

(54) holding the outlet manifold (50) to the fluid

covers (51).

3. Remove the seats (101), balls (201), and o-rings

(102) from the fluid covers (51).

4. Remove the inlet manifold bolts (54).

5. Remove the seats (101), balls (201), and o-rings

(102) from the fluid covers (51).

Reassembly (See Fig. 6)

1. Clean all parts, and inspect for wear or damage.

Replace parts as needed.

2. Reassemble in the reverse order, following all

notes in Fig. 6. Be sure all parts are assembled

exactly as shown.

NOTE: To ensure proper seating, visually check

that the manifold (50 or 53) is centered on the fluid

covers (51) before you tighten the screws (54).

Torque to 55 to 60 ft-lb (75 to 81 NSm). See Torque

Sequence, page 25.

Fig. 6

1

2

The ball seat is on the same side as the step for the

o-ring (102).

06325

50

51

54

54

102

101

102

201

201

53

1

1

2

101

2

3

To ensure proper seating, visually check that the

manifold (50 or 53) is centered on the fluid covers

(51) before you tighten the screws (54).

3

3