16 308639

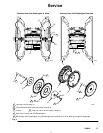

Service

Disassembly

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 9.

WARNING

Some of the pump parts and assemblies are heavy.

Use proper lifting equipment and techniques.

2. Remove the manifolds and disassemble the ball

check valves as explained in Ball Check Valve

Repair on page 14.

3. Using a 15-mm socket wrench, remove the

screws (54), and pull the fluid covers off the pump.

See Fig. 7.

For steps 4 to 9, see Fig. 8.

4. Using 15/16-in. wrenches or sockets, loosen but

do not remove one of the diaphragm plate bolts

(62). (whichever one turns)

5. Remove the fluid-side plate (52), diaphragm (301),

and air-side plate (57).

For models with PTFE diaphragms, also remove

the shim (302) and back-up diaphragm (303).

6. Pull the other diaphragm assembly and the

diaphragm shaft (14) out of the center housing (2).

Hold the shaft flats with a 7/8-in. wrench, and

remove the remaining fluid-side plate (52) from the

shaft. Disassemble the remaining diaphragm

assembly.

7. Inspect the diaphragm shaft (14) for wear or

scratches. If it is damaged, inspect the bearings

(13) in place. If the bearings are damaged, see

Removing and Replacing Bearings and Air

Gasket on page 18.

8. Reach into the center housing (2) with an o-ring

pick, and hook the u-cup seals (15), then pull them

out of the housing. This can be done with the

bearings (13) in place.

9. Clean all parts and inspect for wear or damage.

Replace parts as needed.

Reassembly (See Fig. 8)

1. Install each u-cup seal (15) so the lips face away

from the center of the pump. Lubricate the u-cup

seals.

2. Install a diaphragm assembly on one end of the

shaft (14) as follows:

a. Place a washer (63) and then a white o-ring

(64) on the diaphragm bolt (62). The o-ring

may fit very snugly on the bolt. Insert the bolt

into the fluid-side diaphragm plate (52) as

shown in Fig. 8. Grease the bolt threads.

b. Lay the diaphragm (301) into the grooves on

the fluid-side diaphragm plate (52) so that the

side marked AIR SIDE faces the center of the

pump.

For models with bolt–through PTFE

diaphragms, also install the shim (302) and

back-up diaphragm (303), as shown in Fig. 8.

Line up diaphragm tabs with tabs on air cover.

The bolts must go through the bolt–through

PTFE diaphragm.

c. Place the air-side diaphragm plate (57) and

washer (63) over the bolt. Screw the shaft

(14) onto the bolt handtight.

3. Grease the length of the shaft (14), and slide it

through the center housing (2).

4. Assemble the other diaphragm assembly to the

shaft as explained in step 2.

Step 5 is easiest if the pump is mounted vertically in a

vise.

5. Torque the bolts (62) to 100 to 120 ft-lb (136 to

163 NSm).

WARNING

Failure to properly torque the diaphragm bolts (62)

could result in a bolt failure. If a diaphragm bolt

fails, fluid is exhausted through the muffler. See

Air Exhaust Ventilation on page 7.

6. Install the fluid cover screws (54) hand tight.

Torque the screws to 55 to 60 ft-lb (75 to 81 NSm)

in a crossing pattern. See Fig. 7. See Torque

Sequence, page 25.

7. Reassemble the ball check valves and manifolds

as explained on page 14.