33

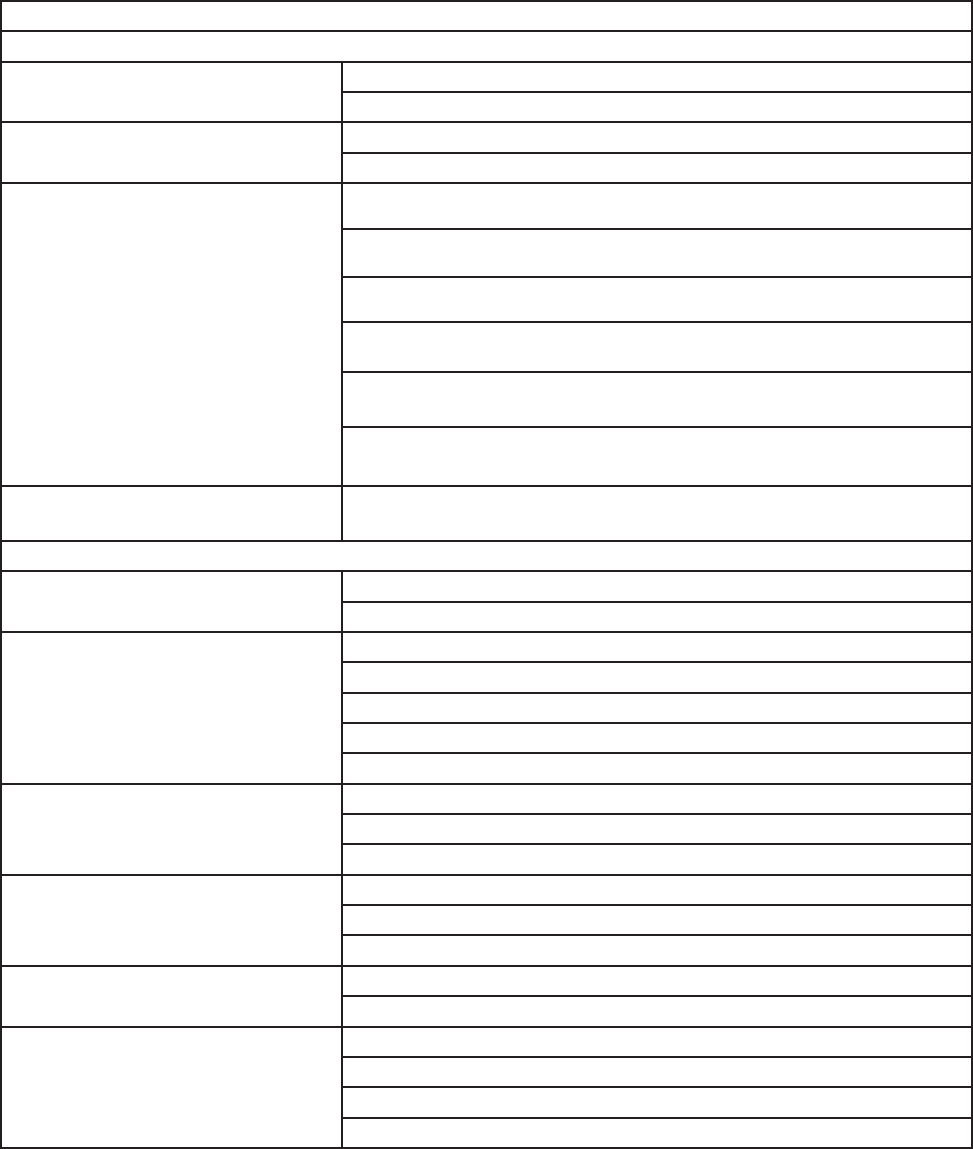

F. Diagnostic Charts

The diagnostic charts below list possible reasons for problems with ice production and

shutdown. Before consulting the diagnostic charts, check for correct installation, proper

voltage per unit nameplate, and adequate water supply.

1. Auxiliary Codes A-1 and Earlier

No Ice Production - Possible Cause

Startup

1. Power Supply a) Unplugged, off, blown fuse, or tripped breaker.

b) Not within specications.

2. Power Switch a) "OFF" position.

b) Bad contacts.

3. Bin Control Thermostat Assembly

(with integrated heater)

NOTICE! Some units contain

a sticker that states: "The

bin control heater has been

disconnected. DO NOT

reconnect the bin control

heater." In this case, leave

the bin control heater

disconnected or replace

the bin control thermostat

assembly with 3A2561A03.

a) Open with bin lled with ice.

b) Ambient temperature too cool.

c) Out of position.

d) Out of adjustment. See "IV.C. Bin Control Check."

e) Bad contacts.

f) Bad thermostat heater (if applicable).

4. Optional Drain Pump HS-0248

Safety

a) Open.

Freeze Cycle

1. Water Supply a) Water supply off or improper water pressure.

b) External water lters clogged.

2. Gear Motor a) Gear motor external protector (2.4~3.0A) tripped.

b) Gear motor internal protector open or windings open.

c) Bad gear motor capacitor.

d) Locked bearings.

e) Spline coupling or gear broken and auger not turning.

3. Suction Temperature Safety

(Low Water/Freeze-Up Safety)

a) Open due to water supply cut-off.

b) Open due to evaporator freeze-up (gear motor not operating).

c) Bad contacts.

4. Fan Motor a) Motor winding open.

b) Bearing worn out or locked rotor.

c) Fan blade does not move freely.

5. Compressor Relay a) Open coil.

b) Open contacts.

6. Compressor a) Compressor external protector open or defective.

b) Motor winding open.

c) PTC relay contacts bad or coil winding open.

d) Inefficient.