20

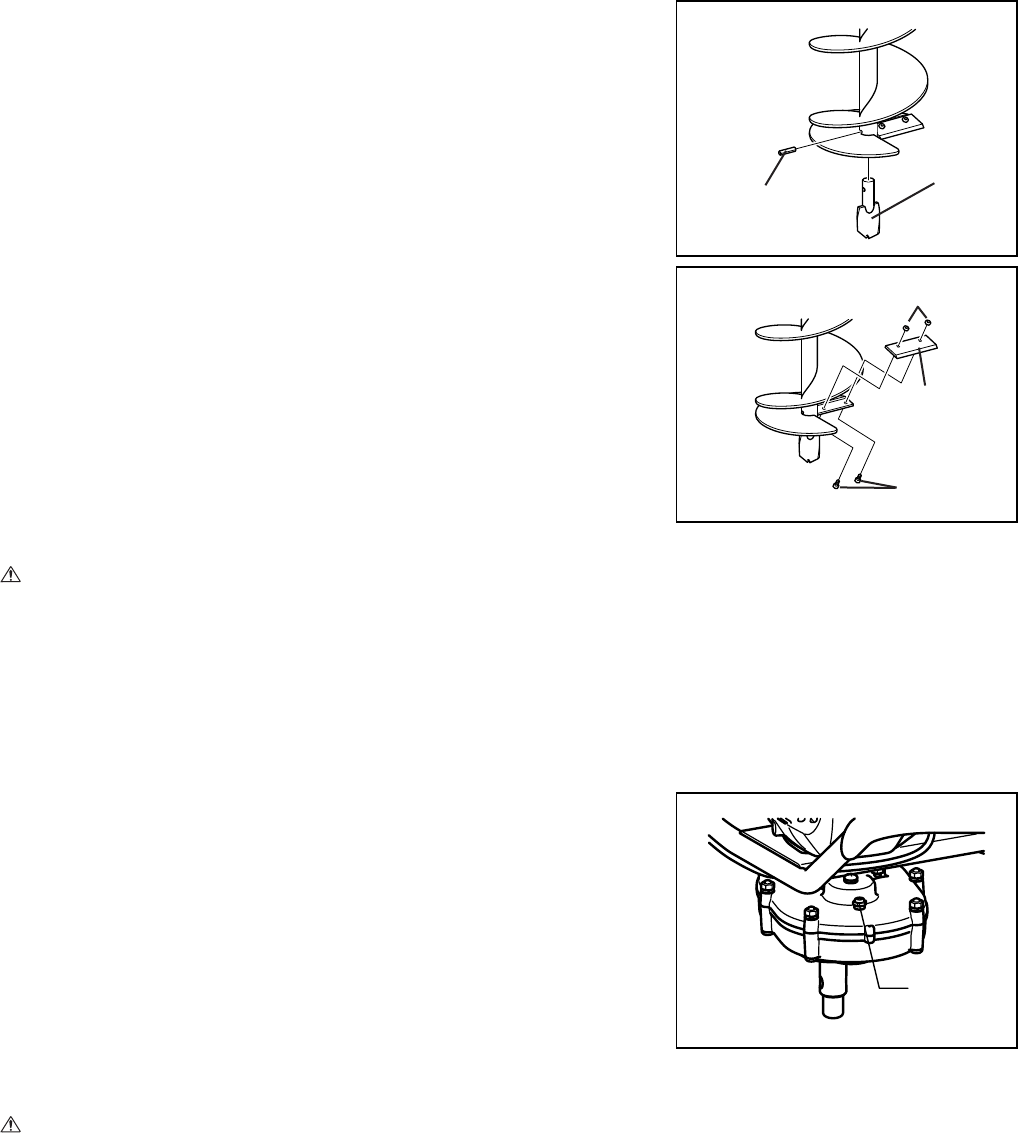

REPLACING A WORN SCREW BIT

Inspect the auger bit for worn or broken components. Check if the auger does not have a bent

or damaged axle. A bent or damaged axle causes the auger bit to “wobble” during use. Maxi-

mum allowable auger wobble is 7 mm (0.25") total indicated runout (TIR). An auger bit with a

total indicated runout wobble in excess of this value must be removed from service and

scrapped.

1) Using the hammer and drift-type punch, remove the roll pin from the auger bit.

2) Remove the worn screw bit from the auger bit. Align the hole of the replacement screw bit

with the hole drilled in the auger bit.

3) Install the roll pin with the hammer and drift-type punch.

REPLACING A WORN AUGER BLADE

All blades utilize 1/4 inch diameter capscrews, lock washers and standard nuts to retain the

blade to the auger bit.

Each blade incorporates a minimum of two capscrews. A worn auger that has only one cap-

screw is worn beyond its useful service life and must be discarded.

1) Using the 7/16 inch wrenches, loosen the capscrews to remove the worn blade from the

auger bit.

2) Remove any accumulated dirt.

3) Install the replacement blade with the capscrew threads facing up toward the hub. The

replacement blade extends past the outside diameter of the auger bit so that the blade

provides added component protection.

Tighten firmly with the wrenches.

CHANGING THE EARTH AUGER TRANSMISSION LUBRICANT

CAUTION:

• Observe all applicable safety precautions for the solvent. Dispose of the used transmission lubricant according to all applicable laws and reg-

ulations.

Earth auger uses a fully enclosed, double reduction transmission for multiplying and transmitting engine torque to the auger bit. The principle

involves engine horsepower and torque being transmitted through a centrifugal clutch and two sets of gear reductions into a final drive shaft.

Grease is provided for lubrication and heat dissipation for the bearings, gears and clutch assembly.

The transmission is originally filled with approximately 8 ounces (224 g) of high temperature lubricant. This lubricant contains an extreme pres-

sure additive which enables the gear teeth to cling at high rotational speeds.

Pressure relief valve

A pressure relief valve is located on the top surface of the transmission cover to relieve any

excess pressure created in the transmission due to heat rise. If this valve becomes clogged,

the following problems may occur:

a) Lubrication grease is forced out between the bearings and the final driveshaft.

b) The gasket that separates the two halves of the transmission pushes out, causing a loss of

lubrication grease.

To prevent these problems, clean the pressure relief valve at regular intervals with an

approved safety solvent.

Transmission lubricant

CAUTION:

• Before changing the transmission lubricant, drain the fuel from the fuel tank into an approved container. Wipe any excess spilled fuel and dis-

card them properly.

Interval of replacement: every 50 hours of operation

Change the transmission lubricant every 50 hours of operation, or more often as necessary, if the earth auger is operated in extremely dusty or

dirty conditions.

Roll pin

Screw bit

Hex nut

Blade

Screw

Pressure relief

valve