Portable Hot Oil Temperature Control Units Page 31

Chapter 6: Preventive Maintenance

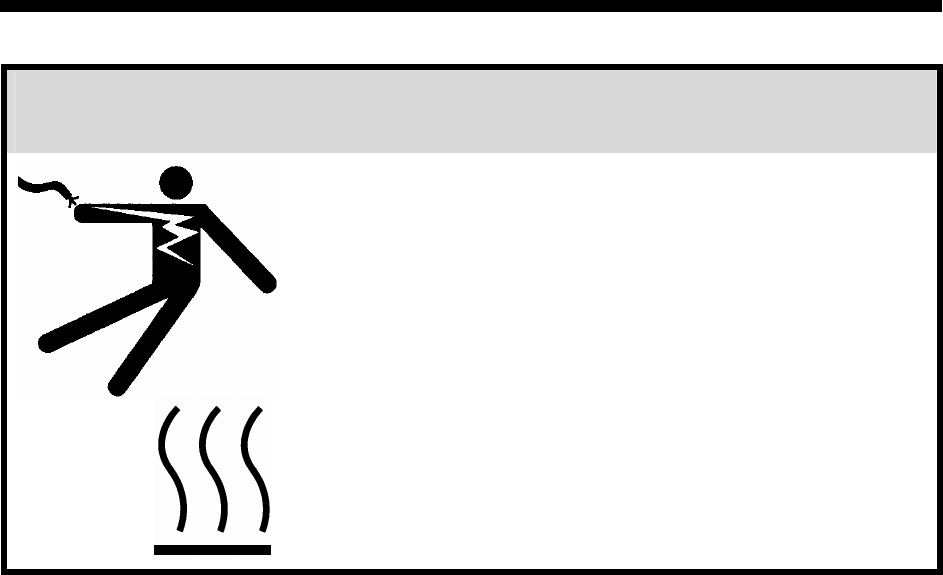

! WARNING

Make sure that your maintenance

technicians comply with lock-out/tag-out

procedures during any servicing or

maintenance of this unit and related

equipment, per OSHA article ART 1910.147.

Before you begin servicing this unit,

disconnect all power to the unit, let the unit

cool down completely, and turn off the

water.

Failure to follow these directives can result

in serious injury or death!

6-1 Periodic Checks

Making Daily Checks

• Check fluid level; add fluid as needed.

• Check all connecting lines, hoses, and connectors for wear or

damage.

Making Monthly Checks

• Check for leaks developing at the pump seal, gaskets, and other

similar locations.

• Check the pump drive V belt for any wear.

• Check the reservoir tank vent for any obstructions.

Making Quarterly Checks

• Check the heat transfer fluid for deterioration. If the fluid is

noticeably darker, or it seems significantly thicker, drain the

system and replace the fluid with fresh, new recommended heat

transfer fluid.

Do a routine check of the fluid every 1,000 hours of operation or

every three (3) months, whichever comes first. Contact the Service

Department for information on fluid testing.