Setup

3A1569B 19

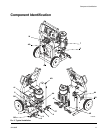

Recirculation / Pressure Relief

Lines

If Recirculating to Supply Drum: Connect high

pressure hose (R) to relief fittings (BA, BB) of both

PRESSURE RELIEF/SPRAY valves. Route hose back

to component A and B drums. Refer to manual 309852.

Alternate recirculation hoses (requires adapter

fittings):

249508 - ISO (A) (moisture guard) red hose, 1/4 in. (6

mm) ID; #5 JIC fittings (m x f); 35 ft (10.7 m) long.

249509 - Resin (B) blue hose; 1/4 in. (6 mm) ID, #6 JIC

fittings (m x f), 35 ft (10.7 m) long.

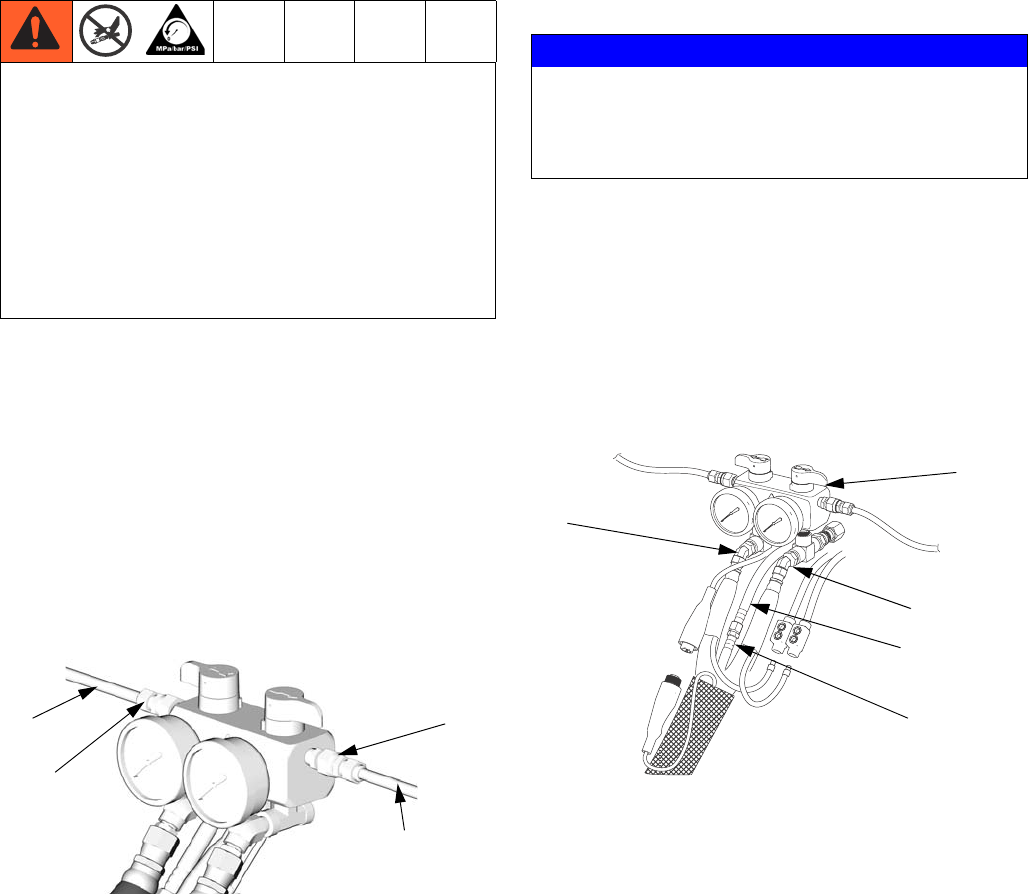

Install Fluid Temperature Sensor

(FTS)

Install FTS between main hose and whip hose. See

Heated Hose manual for instructions.

Connect Heated Hose

NOTE: See heated hose manual for detailed instruc-

tions for Graco heated hoses.

1. Turn main power OFF.

2. Assemble heated hose sections, FTS, and whip

hose. See Heated Hose manual for instructions.

3. Connect A and B hoses to A and B outlets on

Reactor fluid manifold (FM). Hoses are color coded:

red for component A (ISO), blue for component B

(RES). Fittings are sized to prevent connection

errors.

NOTE: Manifold hose fittings (VV, WW) allow use of 1/4

in. and 3/8 in. ID Reactor heated fluid hoses.

4. Connect heated hose air line (AH) to proportioner

air hose.

Do not install shutoffs downstream of the

PRESSURE RELIEF/SPRAY valve outlets (BA, BB).

The valves function as over pressure relief valves

when set to SPRAY. Lines must be open so valves

can automatically relieve pressure when machine is

operating.

If circulating fluid back to the supply drums, use high

pressure hose rated to withstand the maximum

working pressure of this equipment.

BB

BA

ti8441a

R

R

NOTICE

The fluid temperature sensor (FTS) and whip hose

must be used with heated hose; see page 19. Hose

length, including whip hose, must be 60 ft (18.3 m) min-

imum.

FM

VV

WW

ti17788a

AH

PH