Installation & User Manual

June 2013 Ed 19UK

Page 27 of 28

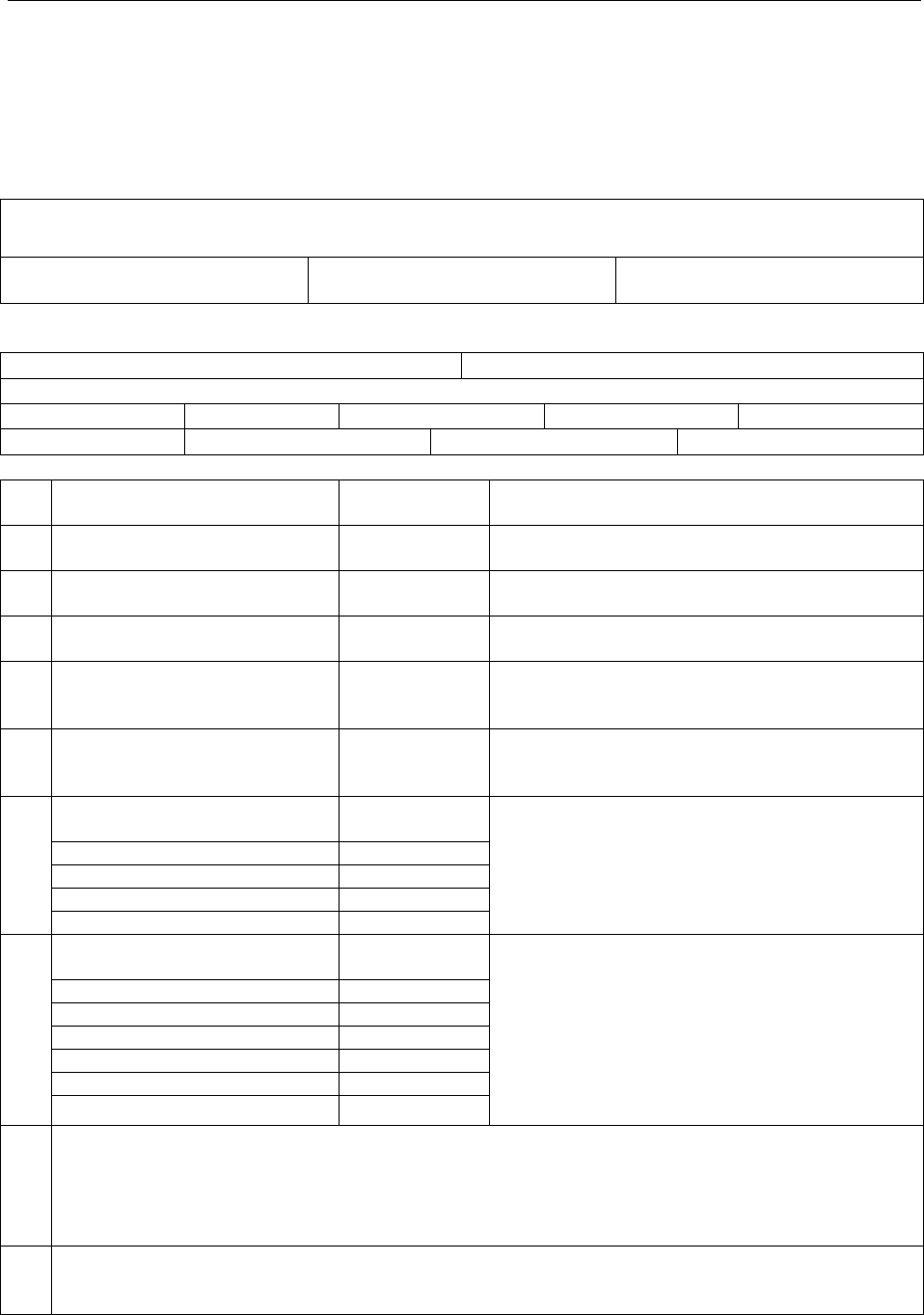

MAS2600 Test sheet

ATT.: Emerson Process Management

Marine Solutions

Damcos A/S, Service Department

FAX.: +45 5578 7272

Name:

Ship name:

Yard:

NB No:

MAS2600:

Transducer serial no.:

Amplifier serial no.:

Tank name:

Liquid in tank

HFO:

DO:

Ballast:

Other:

The tank is

Full:

Empty:

Other:

Measurements:

1

Measure voltage between terminal

5 and 6

V DC

Voltage should be in the range 14 to 33 V DC.

Check power supply.

2

Measure ripple voltage between

terminal 5 and 6

V AC

Voltage must not exceed 2 V AC. Check power

supply.

3

Measure sensor excitation voltage

between terminal 7 and 10

V DC Voltage should be in the range 3.0 to 6.2 V DC

4

Measure sensor excitation voltage

between terminal 8 and 9

mV DC Voltage should be in the range -15 to 100 mV DC

5

Measure current in supply lead to

terminal 5 mA DC

Current should be in the range 4 to 20 mA and the

same value as measured in point 6. If not the

amplifier may be defect.

6

Measure current in supply lead to

terminal 6 mA DC

Current should be in the range 4 to 20 mA and the

same value as measured in point 5. If not the

amplifier may be defect.

7

Measure sensor resistance with

sensor cable unconnected

If the resistance measured is less that 1 M Ohm the

sensor is defect.

Terminal 7 to cable shield

M Ohm

Terminal 8 to cable shield

M Ohm

Terminal 9 to cable shield

M Ohm

Terminal 10 to cable shield

M Ohm

8

Measure sensor bridge resistance

with sensor cable unconnected

If the resistance measured is less than 1 K Ohm or

greater that 50 K Ohm the sensor is defect.

Terminal 7 to Terminal 8

K Ohm

Terminal 7 to Terminal 9

K Ohm

Terminal 7 to Terminal 10

K Ohm

Terminal 8 to Terminal 9

K Ohm

Terminal 8 to Terminal 10

K Ohm

Terminal 9 to Terminal 10

K Ohm

9

Visual inspection of the transmitter:

Is the cable damaged?

Are there sharp bends on the cable?

Are there moisture/liquids in the breather tube?

Is the diaphragm damaged?

10

Comments: