4. INSTALLATION

40

3. Using a 4 mm, #23, or 9/64" bit, drill three

holes 22 mm (7/8") deep at the locations

indicated. To prevent drilling too deeply,

wrap masking tape around the bit 22 mm

(7/8") from the point.

Fiberglass hull: Minimize surface crack-

ing by chamfering the gelcoat. If a cham-

fer bit or countersink bit is not available,

start drilling with a 6mm or 1/4" bit to a

depth of 1 mm (1/16").

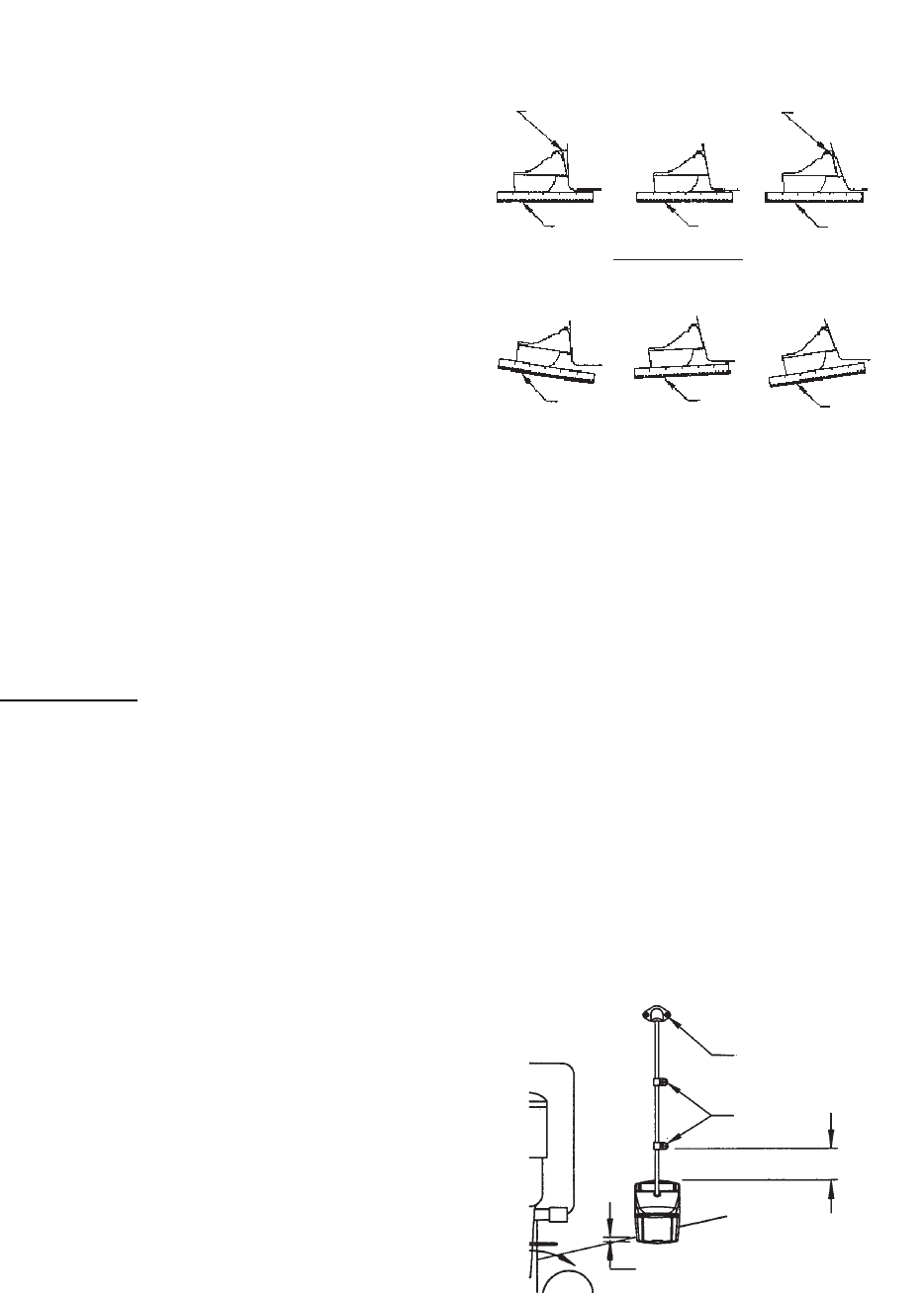

4. If you know your transom angle, the

bracket is designed for a standard 13°

transom angle.

11°-18° angle: No shim is required. Skip

to step 3 in "Adjustments".

Other angles: The shim is required. Skip

to step 2 of "Adjustments".

If you do not know the transom angle,

temporarily attach the bracket and sensor

to the transom to determine if the plastic

shim is needed.

5. Using the three #10 x 1-1/4" self-tapping

screws, temporarily screw the bracket to

the hull. DO NOT tighten the screws com-

pletely at this time. Follow the step 1-4 in

"Attaching the sensor to the bracket", be-

fore proceeding with "Adjusting".

Adjustments

1. Using a straight edge, sight the underside

of the sensor relative to the underside of

the hull. The stern of the sensor should be

1-3 mm (1/16-1/8") below the bow of the

sensor or parallel to the bottom of the hull.

Note: Do not position the bow of the sen-

sor lower than the stern because aeration

will occur.

2. To adjust the sensor's angle relative to

the hull, use the tapered plastic shim pro-

vided. If the bracket has been temporarily

fastened to the transom, remove it. Key

the shim in place on the back of the brack-

et.

2°-10° transom angle (stepped tran-

som and jet boats): Position the shim

with the tapered end down.

19°-22° transom angle (small alumi-

num and fiberglass boats): Position the

shim with the tapered end up.

Sensor position and transom angle

3. If the bracket has been temporarily fas-

tened to the transom, remove it. Apply a

marine sealant to the threads of the three

#10 x 1-1/4" self tapping screws to pre-

vent water seeping into the transom.

Screw the bracket to the hull. Do not tight-

en the screws completely at this time.

4. Repeat step 1 to ensure that the angle of

the sensor is correct.

Note: Do not position the sensor farther

into the water than necessary to avoid in-

creasing drag, spray, and water noise

and reducing boat speed.

5. Using the vertical adjustment space on

the bracket slots, slide the sensor up or

down to provide a projection of 3 mm (1/

8"). Tighten the screws.

Vertical adjustment and cable routing

2°-10°

transom

angle

11° transom angle

NO SHIM

19°-22°

transom

angle

shim with

taper down

shim with

taper up

YES

YES

YES

parallel parallel

parallel

12°-18° transom angle

NO SHIM

NO NO

YES

angle

reversed

slight

angle

angle too

steep

Cable cover

Cable

clamp

50 mm (2")

Hull projection 3 mm (1/8")