190-00906-01 GTX 23 Installation Manual

Rev. C Page B-5

Secondary Method:

Solder a Flat Braid (Item 6) to the shield exposed through the window of the prepared cable assembly

(Item 4). Ensure a solid electrical connection through the use of acceptable soldering practices. Use

care to avoid applying excessive heat that burns through the insulation of the center conductors and

shorts the shield to the signal wire. Slide a minimum 0.75 inches of Teflon heat shrinkable tubing

(Item 5) onto the prepared wire assembly and shrink using a heat gun. The chosen size of heat

shrinkage tubing must accommodate both the number of conductors present in the cable and the Flat

Braid (Item 6) to be attached.

Teflon Heat Shrinkable Tubing:

Reference the following MIL-Spec for Teflon heat shrinkable tubing (M23053/5-X-Y).

4. At the same end of the shielded cable (Item 4) and ahead of the previous shield termination, strip

back “Float Min” to “Float Max” (Table B-2) length of jacket and shield to expose the insulated

center conductors (Figure B-2). The “Ideal Float” length may be best to build optimally.

Preferred Method:

The jacket and shield should be cut off at the same point so no shield is exposed. Slide 0.75 inches

minimum of Teflon heat shrinkable tubing (Item 7) onto the cable and use a heat gun to shrink the

tubing. The chosen size of heat shrinkage tubing must accommodate the number of conductors present

in the cable.

Secondary Method:

Leave a max 0.35 inches of shield extending past the jacket. Fold this 0.35 inches of shield back over

the jacket. Slide a solder sleeve (Item 7) over the end of the cable and use a heat gun approved for

solder sleeves to secure the connection. The chosen size of solder sleeve must accommodate the

number of conductors present in the cable.

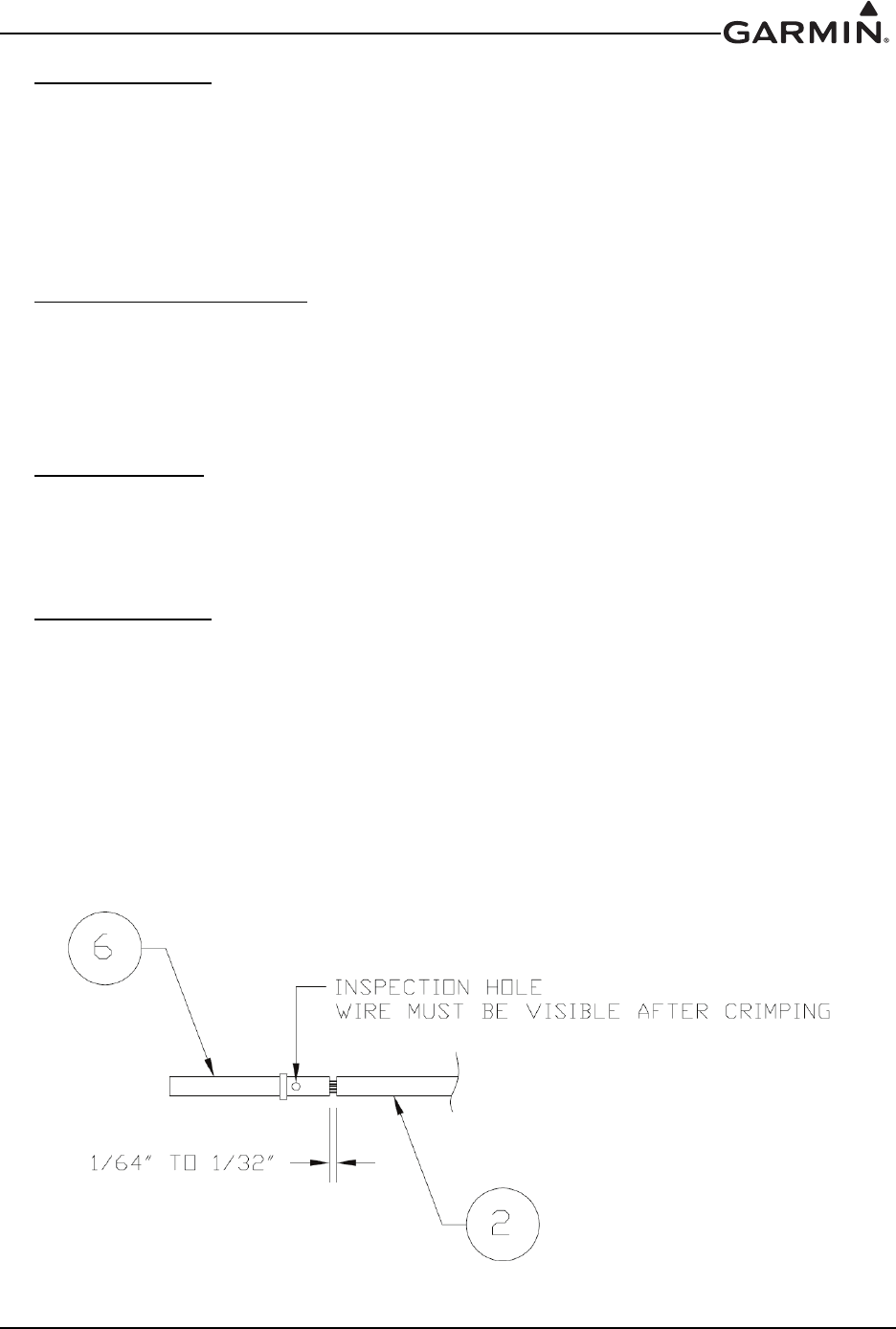

5. Strip back approximately 0.17 inches of insulation from each wire of the shielded cable (Item 4)

and crimp a contact (Item 8) to each conductor. It is the responsibility of the installer to determine

the proper length of insulation to be removed. Wire must be visible in the inspection hole after

crimping and the insulation must be 1/64 – 1/32 inches from the end of the contact as shown in

Figure B-3.

Figure B-3 Insulation/Contact Clearance