30 GHP 10 Marine Autopilot System Installation Instructions

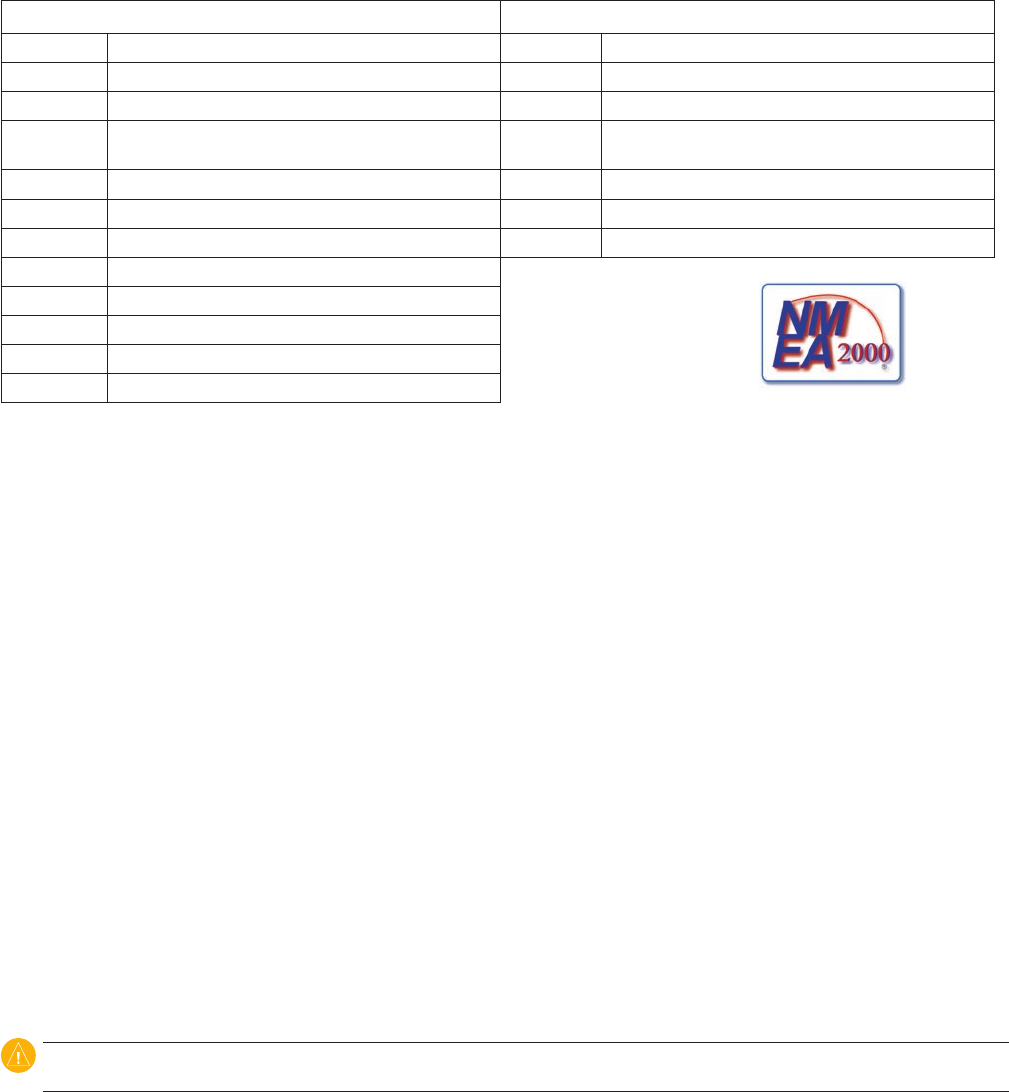

CCU

Receive Transmit

059392 ISO Acknowledgment 059392 ISO Acknowledgment

059904 ISO Request 059904 ISO Request

060928 ISO Address Claim 060928 ISO Address Claim

126208 NMEA - Command/Request/Acknowledge Group

Function

126208 NMEA - Command/Request/Acknowledge Group

Function

126464 Transmit/Receive PGN List Group Function 126464 Transmit/Receive PGN List Group Function

126996 Product Information 126996 Product Information

127258 Magnetic Variation 127250 Vessel Heading

127488 Engine Parameters - Rapid Update

129025 Position - Rapid Update

The GHP 10 and the GHC 10

are NMEA 2000 certied.

129026 COG & SOG - Rapid Update

129283 Cross Track Error

129284 Navigation Data

NMEA 0183 Information

The GHC 10, when connected to an optional NMEA 0183-compatible GPS device, uses the following NMEA 0183 sentences:

Receive—wpl, gga, grme, gsa, gsv, rmc, bod, bwc, dtm, gll, rmb, and xte.

Transmit

—hdg.

Installing an Unbalanced Kit on a 1.2 L or 2.0 L Pump

If your boat has an unbalanced cylinder steering system, then you need to install the optional unbalanced kit. Do not use a 2.1 L

pump on an unbalanced cylinder steering system.

To install the unbalanced kit:

1. Loosen and remove the four screws that hold the manifold to the pump body. Remove the manifold from the pump body.

2. Replace the O-rings on the pump body with the O-rings supplied in the unbalanced kit.

3. Place the unbalanced valve between the pump body and the manifold, with the O-rings on the unbalanced valve facing the

manifold. There are six O-rings—three on the pump body, and three on the unbalanced valve.

4. Use the four longer screws included in the unbalanced kit to connect the manifold and unbalanced valve to the pump body. Use

thread-locking compound and tighten the screws to 35 inch-pounds of torque.

Adjusting and Calibrating the Unbalanced Valve

The brass screws on the sides of the unbalanced valve adjust the valve. Compare the amount of screw protruding beyond the valve

body on both sides of the valve. Both screws should protrude the same distance. To recalibrate the screws, fully tighten both of them

until they stop. Be sure they protrude the same distance after they stop. If not, loosen the shorter screw until they protrude the same

distance. Unscrew each screw by two and one-half full turns. The valve is ready for use.

CAUTION: Do not unscrew the brass screws more than the specied amount. Do not operate the system with the brass screws fully

tightened.