26

Inside the Hull Mount - DualBeam PLUS™

6. Run the boat at various speeds and water depths while observing

the screen on the control head. If depth performance is required,

test the transducer in water at the desired depth. If the performance

is acceptable, move on to Step 7. If the performance is not

acceptable, repeat Steps 3 through 6.

7. Once you have determined the best mounting location using the

above steps, mark the position of the transducer.

3. Routing the cable

1. Once the mounting location is determined and you have marked the

position of the transducer, route the cable from the transducer to

the control head.

4. Permanently mounting the transducer

1. Make sure the position of the transducer is marked.

2. You may have to disconnect the cable to the control head and

reconnect it at the end of this procedure.

3. Remove the water from inside the hull and thoroughly dry the

mounting surface. If the surface is excessively rough, it may be

necessary to sand the area to create a smooth mounting surface.

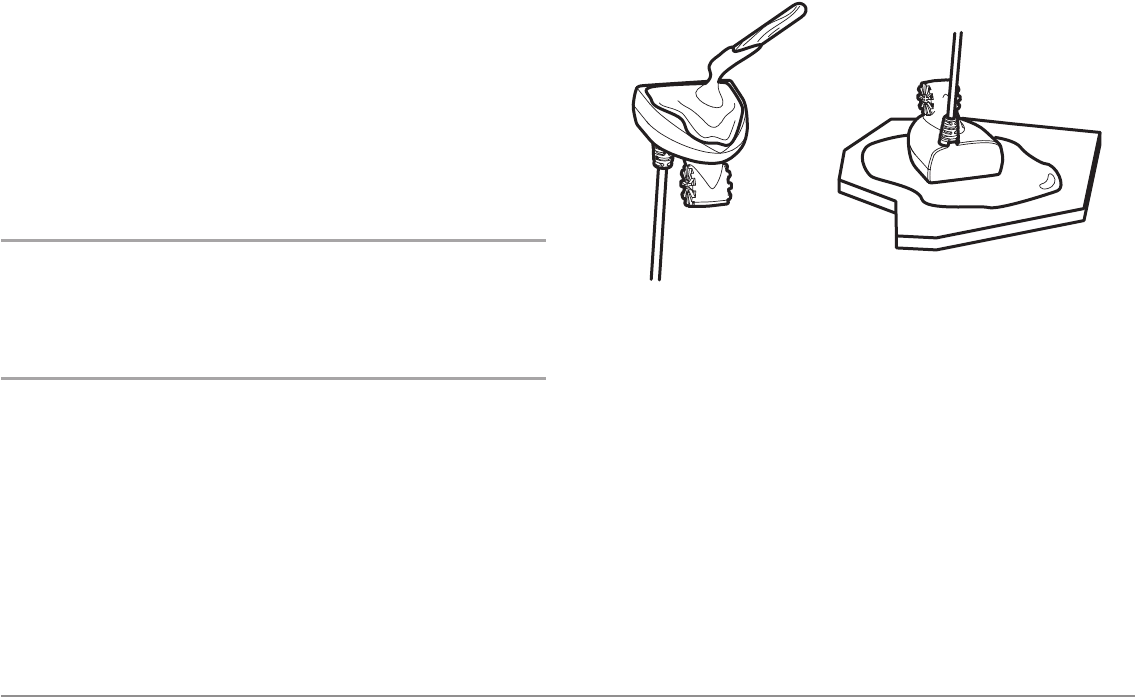

4. Slowly and thoroughly mix an ample quantity of two-part slow cure

epoxy. Avoid trapping air bubbles.

5. Coat the face of the transducer and the inside of the hull with epoxy.

6. Press the transducer into place with a slight twisting motion to

purge any trapped air from underneath, keeping the end of the

transducer that has the mounting knuckle pointed forward, towards

the bow of the boat.

NOTE: Proper operation requires the end of the transducer that has the mounting

knuckle to face towards the bow of the boat.

7. Weight the transducer so that it will not move while the epoxy is

curing.

NOTE: When the epoxy cures, no water is necessary inside the hull.

8. If you unplugged the transducer cable at the beginning of this

procedure, plug it back into the control head.

NOTE: Neither water, spilled gasoline, nor oil will affect the performance of the

transducer.