15

INSTALLATION

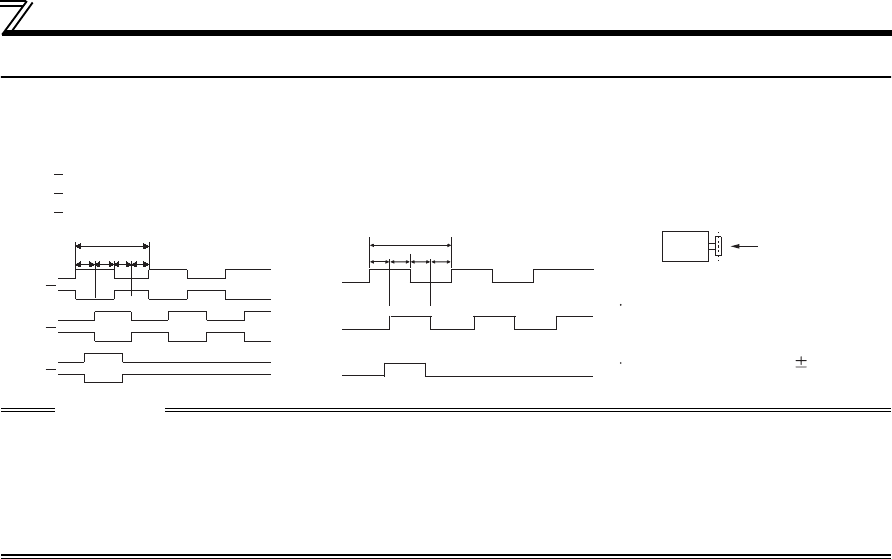

2.6 Encoder

(1) Position detection (pulse encoder)

CAUTION

⋅ When orientation control, encoder feedback control, vector control are used together, the encoder is shared

between these controls.

Use an encoder which has a pulse count of 1000 to 4096ppr (pulse per revolution).

⋅

The encoder should be coupled with the motor shaft or the spindle oriented with a speed ratio of 1 to 1 without any

mechanical looseness.

⋅ To ensure correct operation, the encoder must be set in the proper rotation direction and the A and B phases

connected correctly.

P

abcd

H

A

A

B

B

Z

Z

L

A/A signal 1000P/R to 4096P/R

B/B signal 1000P/R to 4096P/R

Z/Z signal 1P/R

A signal 1000P/R to 4096P/R

B signal 1000P/R to 4096P/R

Z signal 1P/R

Differential line driver Complementary

Output pulse specifications

A

Position detector

Encoder

When rotation is clockwise

as viewed from the shaft

end (A) of the encoder.

a, b, c, d should be (1/4

1/8)P

A

B

Z

abcd

P