10

Installation and Set-Up

Receiving And Handling

After the machine has been uncrated, examine the

case sealer for damage that might have occurred

during transit. If damage is evident, file a damage

claim immediately with the transportation company

and also notify your 3M Representative.

PACKAGING AND SEPARATE PARTS

1. Remove straps and staples and lift fiberboard

cover off pallet.

2. Remove protective wrapping around machine.

3. Cut and remove cable tie from electrical conduit.

4. Cut cable ties that secure upper assembly to

machine bed on each side.

5. Remove tape drum bracket bolts (4) from top

crossbar and install tape drum bracket from

parts box as shown in Figure 2-1A.

Machine Set-Up

Note – A tool kit consisting of metric open end

and hex socket wrenches is provided with the

machine. These tools should be adequate to set-

up the machine, however, other tools supplied by

the customer will be required for machine

maintenance.

The following instructions are presented in the order

recommended for setting up and installing the case

sealer, as well as for learning the operating

functions and adjustments. Following them step by

step will result in your thorough understanding of the

machine and an installation in your production line

that best utilizes the many features built into the case

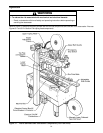

sealer. Refer to Figure 3-1 to identify the various

components of the case sealer.

6. Loosen and move both compression rollers out

so they don't catch on side guides.

7. Install height adjustment crank and locking knob

on top of left column as shown in

Figure 2-1B. Crank upper assembly up high

enough to allow clear access to lower taping

head. Remove and discard the two cushion

shipping blocks.

8. Using 17 mm wrench, remove nuts from top of

side guides. Replace with black knobs from

parts box. Figure 2-1C.

9. Cut and remove cable ties on both upper and

lower taping heads. (Applying/buffing rollers are

held retracted for shipment.)

Hold taping head BUFFING ROLLER and cut

and remove cable tie that holds applying/

buffing arms retracted. See Figure 2-1D.

Allow buffing/applying arms to extend slowly.

10. Install machine stops onto columns as shown in

Figure 2-1E. Use the lowest hole position and

bolt into the lowest threaded insert on the

column.

• To reduce the risk associated with

mechanical and electrical hazards:

− Read, understand and follow all safety and

operating instructions before operating or

servicing the case sealer

WARNING

• To reduce the risk associated with sharp

blade hazards:

− Keep hands and fingers away from tape cutoff

blades under orange blade guards. The

blades are extremely sharp

WARNING