17

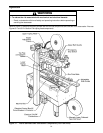

Operation (Continued)

Note – Upper head has unique feature for

overstuffed boxes. The head will raise up to

13 mm [1/2 inch] to compensate for this type

of condition.

3. RUN BOXES TO CHECK ADJUSTMENT

(Figure 3-5)

Turn electrical switch to "On" to start drive belts.

Move box forward under upper taping head until it

is taken away by drive belts. If box is hard to

move under head or is crushed, raise head

slightly. If box movement is jerky or stops under

upper head, lower upper head slightly to add

more pressure between box and drive belts.

4. TOP FLAP COMPRESSION ROLLERS

(Figure 3-6)

The top flap compression rollers have two

mounting positions to provide side compression

through the full range of box widths.

The rollers have been pre-assembled in position

"B" to accommodate box widths from 200 mm

[8 inch] to 545 mm [21.5 inch] maximum.

To accommodate box widths less than 200 mm

[8 inch] to 140 mm [5.5 inch] minimum, move all

four rollers to position "A".

Adjust the top flap compression rollers against

top edge of box and tighten knobs to secure

rollers in operating position.

Important – Before turning drive belts on, be

sure no tools or other objects are on the conveyor

bed.

Important – If drive belts are allowed to slip on

box, excessive belt wear will occur.

Figure 3-6 – Compression Rollers

Figure 3-5 – Check Adjustments

• To reduce the risk associated with pinch

and entanglement hazards:

− Keep hands clear of the upper head support

assembly as boxes are transported through

the machine

CAUTION

• To reduce the risk associated with pinch

and entanglement hazards:

− Keep hands, hair, loose clothing and jewelry

away from box compression rollers.

CAUTION