12

Installation and Set-Up (Continued)

MACHINE BED HEIGHT

Adjust machine bed height. The case sealer is

equipped with four adjustable legs that are

located at the corners of the machine frame.

The legs can be adjusted to obtain different

machine bed heights from 610 mm [24 inch]

minimum to 890 mm [35 inch] maximum.

Note – Minimum machine bed height can be

reduced to 520 mm [20.5 inch] by moving

outer columns up one set of mounting holes.

However, this change also increases the

minimum box height of 120 mm [4.8 inch] to

165 mm [6.5 inch]. (See "Special Set-Up

Procedure – Box/Machine Bed Height Range".)

2. Loosen, but do not remove, two M8 x 1.25

socket head screws in one leg (use M6 hex

wrench). Adjust the leg length for the desired

machine bed height. Retighten the two

screws to secure the leg. Adjust all four legs

equally.

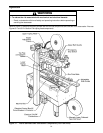

OUTBOARD TAPE ROLL MOUNTING

(Lower Taping Head)

Remove the tape drum bracket assembly, spacer

and fasteners from the lower taping head. Install

and secure on the infeed end of the lower frame,

as shown in Figure 2-2B.

Refer to Figure 2-2C and set the machine bed

height as follows:

Figure 2-2 – Machine Bed Height Adjustment and Lower Tape Drum Bracket Position

1. Use appropriate material handling equipment

and blocking techniques to raise the machine

frame to allow adequate leg adjustment.

• To reduce the risk associated with muscle

strain:

− Use the appropriate rigging and material

handling equipment when lifting or

repositioning this equipment

− Use proper body mechanics when removing

or installing taping heads that are moderately

heavy or may be considered awkward to lift

WARNING