18

Operation (Continued)

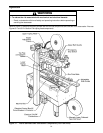

Figure 3-7 – Compression Rollers

Box Sealing

1. Feed boxes to machine at minimum 455 mm

[18 inch] intervals.

2. Reload and thread tape as necessary.

3. Be sure machine is cleaned and lubricated

according to recommendations in "Maintenance"

section of this manual.

Notes –

1. Machine or taping head adjustments are

described in "Adjustments" Section I for

machine or Section II for taping heads.

2. Box drive motors are designed to run at a

moderate temperature of 40°C [104°F]. In

some cases, they may feel hot to the

touch.

5. ADJUST COMPRESSION ROLLERS

Adjust the top flap compression rollers against

top edge of box and tighten knobs to secure

rollers in operating position as shown in

Figure 3-7.

• To reduce the risk associated with pinch

and entanglement hazards:

− Do not leave the machine running while

unattended

WARNING

• To reduce the risk associated with pinch

and entanglement hazards:

− Keep hands clear of the upper head support

assembly as boxes are transported through

the machine

− Always feed boxes into the machine by

pushing only from the end of the box

− Keep hands, hair, loose clothing and jewelry

away from box compression rollers

− Keep hands, hair, loose clothing, and jewelry

away from moving belts and taping heads

CAUTION

• To reduce the risk associated with pinch,

entanglement, and hazardous voltage:

− Never attempt to work on any part of the

machine, load tape, or remove jammed boxes

from the machine while the machine is

running

WARNING