Repair

311594Z 33

Motor Installation

NOTE: A NEMA 182/184 TC Frame is required to mate

with gear reducer. If the pump is purchased without a

motor you must order a kit to mate with the gear

reducer. See T

ABLE

1.

1. After removing the old coupler, thoroughly clean the

input shaft and motor shaft, removing any debris.

This ensures proper clearance and fit for the new

coupler.

NOTE: Do not reuse the old keys or setscrews. Use

only the parts supplied with the new coupler kit.

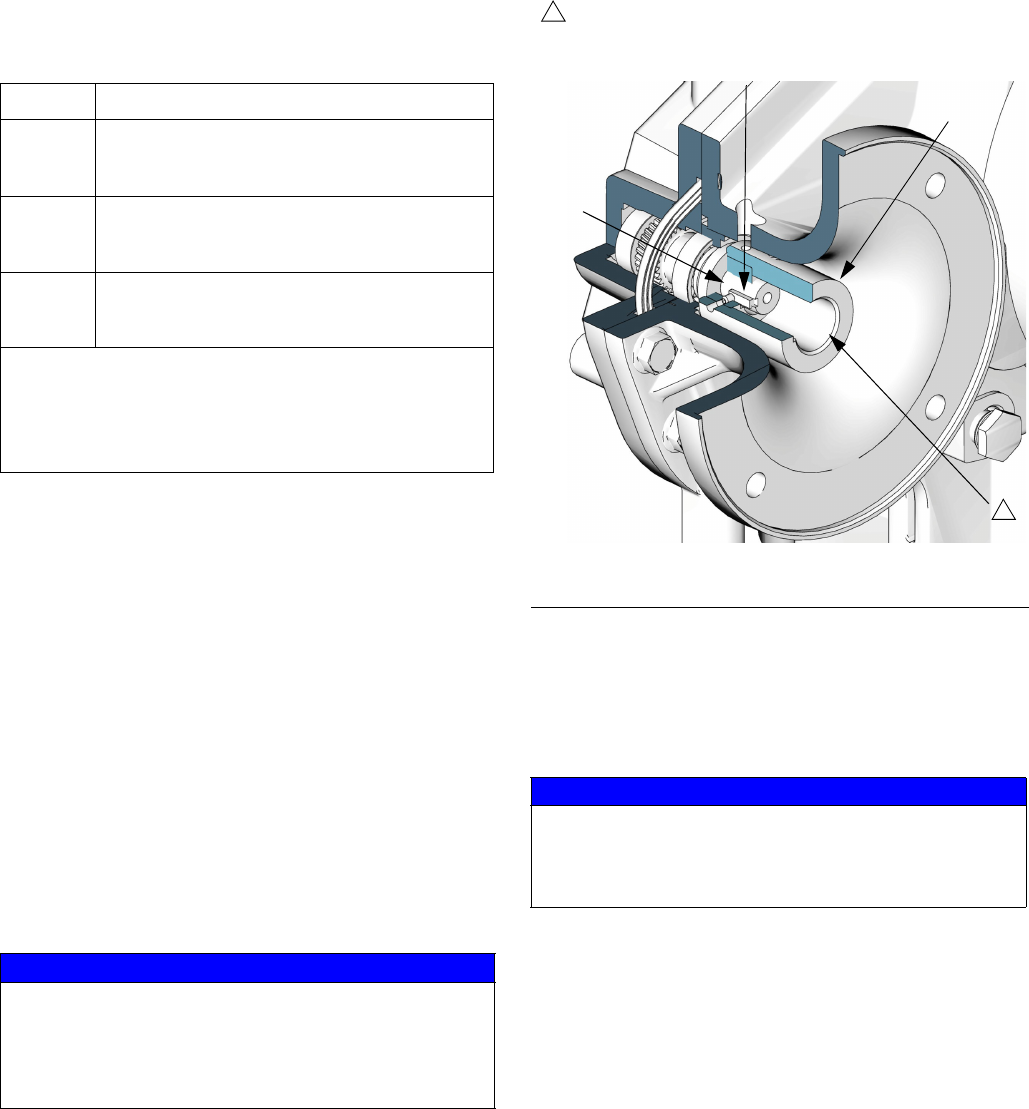

2. See F

IG

. 23. Assemble the key (20) in the input

shaft (105) keyway. Assemble the two setscrews

(31) in the coupler (28), ensuring that they do not

encroach on the keyway or the input shaft bore of

the coupler.

3. Slide the coupler into the gear reducer so the key

and input shaft mate with the coupler. Slide on until

coupler bottoms out on the tapered step of the shaft.

4. Tighten setscrews to 66-78 in-lb (7.4-8.8 N•m).

Apply antiseize lubricant (LPS

®

-04110 or equiva-

lent) to bore of coupling.

NOTE: When installing an IEC 112M/B5 or 100L/B5

Frame electric motor, ensure that the motor adapter

(MA) and screws (MS) are in place before mounting the

motor on the gear reducer. See F

IG

. 21.

5. Lift the motor (19) into position. Align the key (36,

F

IG

. 28) on the motor shaft with the mating slot of

the motor coupler, and the four mounting holes with

the holes in the gear reducer (1). Slide the motor

into place.

6. While one person supports the motor (19), install

the screws (37). Torque to 75-80 ft-lb (102-108

N•m).

Table 1: Motor Adapter Kits

Kit No. Description

16C487 Coupler Kit for NEMA 182-184 TC Frame

3 or 5 HP motors. Includes 2.25 in. (57.2

mm) key★. See manual 311605.

15H880 Coupler Kit for NEMA 182/184 TC Frame

3 or 5 HP motors. Includes 1.75 in. (44.5

mm) key★. See manual 311605.

24E453 Mounts IEC 112M/B5 or 100L/B5 Frame 3

or 5 HP motor to gear reducer★. See

manual 311605.

★NOTE: All kits include the 0.62 in. (15.7 mm) key

(120376). Some kits include an additional motor shaft

key. Measure the length of the motor keyway to deter-

mine the correct key length. Key length should be at

least 90% of keyway length.

NOTICE

Ensure that neither the input key (20) or the end of the

coupler (28) motor shaft bore extend past the end of

the input shaft (105). This could cause the motor shaft

to bottom out on the coupler, causing excessive heat

and bearing damage.

F

IG

. 23. Motor Coupler Installation

NOTICE

When installing the electric motor, always ensure that

the motor shaft key cannot move out of position. If the

key works loose it could cause excessive heat and

equipment damage.

ti8913b

105

28

20

Apply antiseize lubricant (LPS

®

-04110 or equivalent)

to bore of coupling (28).

15

15