Maintenance

MaintenanceMaintenance

Maintenance

Prior to performing any maintenance procedures,

follow Pressure Relief Procedure, page 55.

PreventativePreventative

Preventative

MaintenanceMaintenance

Maintenance

ScheduleSchedule

Schedule

The operating conditions of your particular system

determine how often maintenance is required.

Establish a preventive maintenance schedule by

recording when and what kind of maintenance is

needed, and then determine a regular schedule for

checking your system.

• Inspect hydraulic and uid lines for leaks daily.

• Clean up all hydraulic leaks; identify and repair the

cause of the leak.

• Inspect uid inlet strainer screens daily. See below.

• Keep component A from exposure to moisture to

prevent crystallization.

• Check hydraulic uid level weekly. Check

hydraulic uid level on a dipstick. Fluid level

must be between indent marks on dipstick.

Rell as required with approved hydraulic uid

(see Technical Specications, page 66 and the

Approved Anti-Wear (AW) Hydraulic Oils table in

the Reactor Repair-Parts manual 334946. If uid is

dark in color, change uid and lter.

• Change break-in oil in a new unit after the rst 250

hours of operation or within 3 months, whichever

comes rst. See the table below for recommended

frequency of oil changes.

TableTable

Table

66

6

FrequencyFrequency

Frequency

ofof

of

OilOil

Oil

ChangesChanges

Changes

AmbientAmbient

Ambient

TemperatureTemperature

Temperature

RecommendedRecommended

Recommended

FrequencyFrequency

Frequency

0° to 90° F

(-17° to 32° C)

1000 hours or 12 months,

whichever comes rst

90° F and above

(32° C and above)

500 hours or 6 months,

whichever comes rst

ProportionerProportioner

Proportioner

MaintenanceMaintenance

Maintenance

FluidFluid

Fluid

InletInlet

Inlet

StrainerStrainer

Strainer

ScreensScreens

Screens

Inspect uid inlet strainer screens daily, see

Flush Inlet Strainer Screen, page 58.

GreaseGrease

Grease

CirculationCirculation

Circulation

ValvesValves

Valves

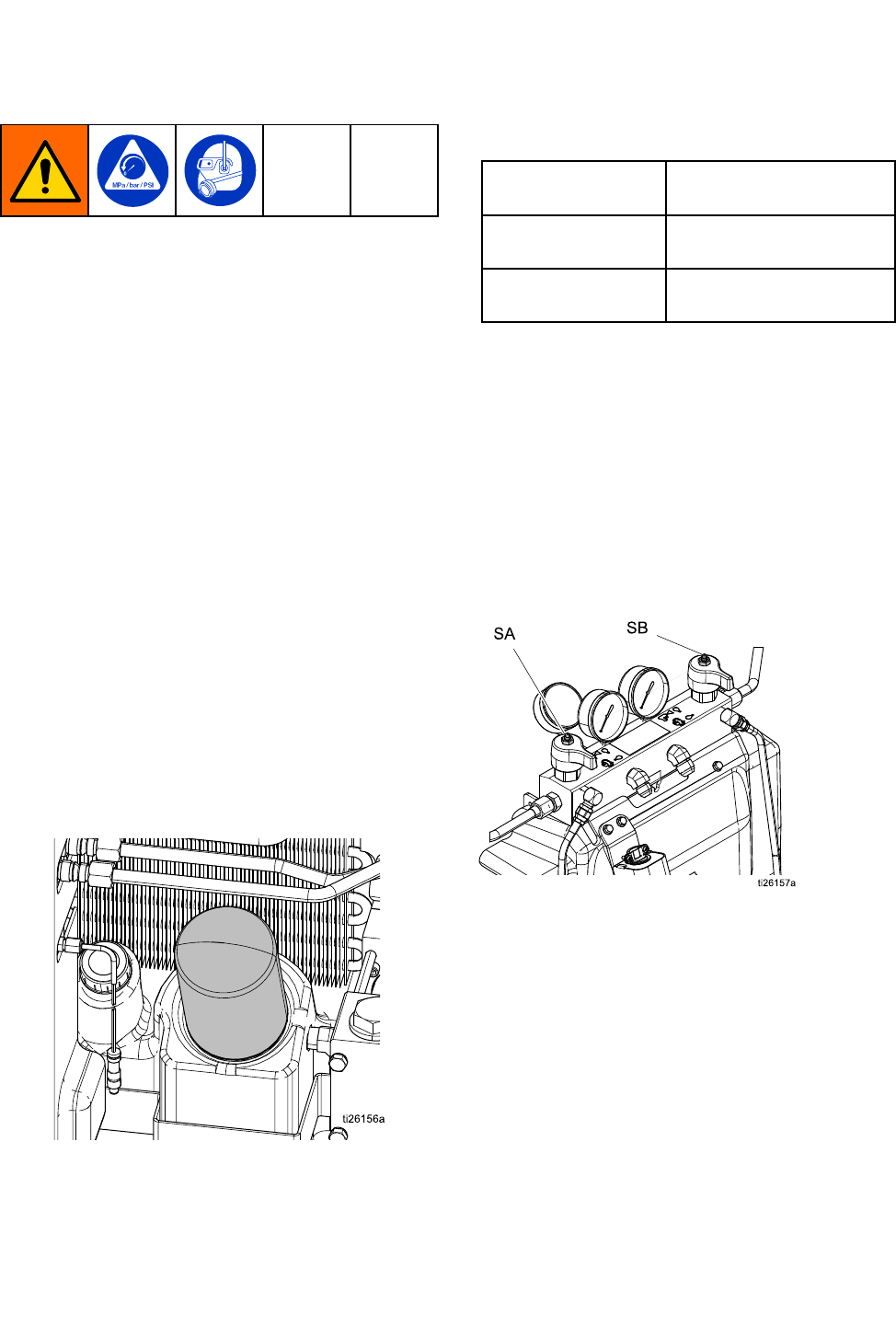

Grease circulation valves (SA and SB) with Fusion

grease (117773) weekly.

ISOISO

ISO

LubricantLubricant

Lubricant

LevelLevel

Level

Inspect ISO lubricant level and condition

daily. Rell or replace as needed. See

Pump Lubrication System, page 59.

MoistureMoisture

Moisture

To prevent crystallization, do not expose component

A to moisture in air.

GunGun

Gun

MixMix

Mix

ChamberChamber

Chamber

PortsPorts

Ports

Clean gun mix chamber ports regularly. See gun

manual.

334945B57