25

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer, refer to your local

yellow pages business listings or go to the Find a Dealer section online at www.Wayne-Dalton.com

Tools Needed:

INSTALLATION

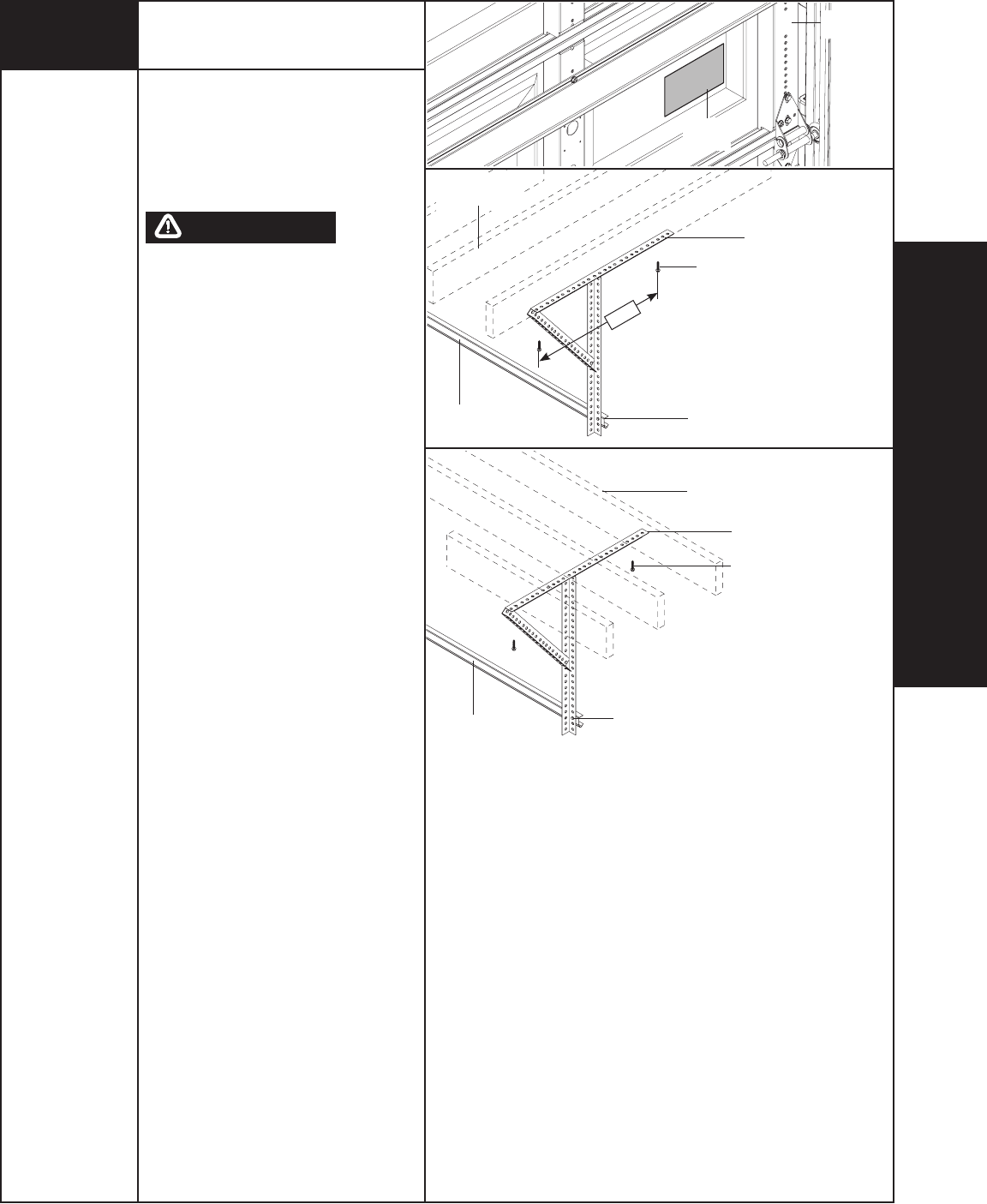

Horizontal

track

Bolt must extend into the track

to serve as a roller stop

Sound framing members

Perforated angle

Perforated angle -bolted using

(2) 5/16” x 1-5/8” hex head

lag screws to ceiling members

and parallel to width of door.

Attach vertical perforated angle

between the (2) 5/16” x 1-5/8”

hex head lag screws, securing

perforated angle to ceiling

members.

Horizontal

track

Perforated angle

Perforated angle - bolted using (2)

5/16” x 1-5/8” hex head lag screws

to ceiling member and parallel to

width of door. Space lag screws no

further than 24” apart.

Sound framing

members

Bolt must extend into

the track to serve as a

roller stop

24”

Rear Support Continued...

To adjust spring tension, fully close door. Apply vice

grips to track above third roller. Insert a winding bar

into the winding cone. On single spring doors, cable

tension must be maintained by placing vice grips

on torsion tube before loosening set screws in the

winding cone. Push upward on the winding bar while

carefully loosening the set screws in the winding

cone.

BE PREPARED TO SUPPORT THE FULL FORCE OF

THE TORSION SPRING ONCE THE SET SCREWS ARE

LOOSE.

Carefully adjust spring tension 1/4 turn. Retighten

both set screws in the winding cone and repeat

for the other side. RECHECK DOOR BALANCE DO

NOT ADJUST MORE THAN 1/2 TURN FROM THE

RECOMMENDED NUMBER OF TURNS.

If the door still does not operate easily, lower the

door into the closed position, UNWIND THE SPRING(S)

FULLY (Reference the insert “Removing The Old Door/

Preparing The Opening” section on torsion spring

removal), and recheck the following the items:

1.) Check the door for level.

2.) Check the torsion tube for level.

3.) Check the track spacing.

4.) Check the counterbalance cables for equal

tension.

5.) Check the track for potential obstruction of the

rollers.

6.) Clamp locking pliers onto track and rewind

springs.

IMPORTANT: IF DOOR STILL DOES NOT OPERATE

PROPERLY, THEN CONTACT A TRAINED DOOR SYSTEM

TECHNICIAN.

Intermediate

section

Windload

label

WARNING